Sealing cover film capable of being peeled after uncovering

A sealing cap and easy-peeling technology, which is applied in the sustainable packaging industry, sustainable manufacturing/processing, packaging recycling, etc., can solve the problems such as easy spillage of the contents, to avoid easy spillage or leak detection, convenient use, The effect of recycling convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

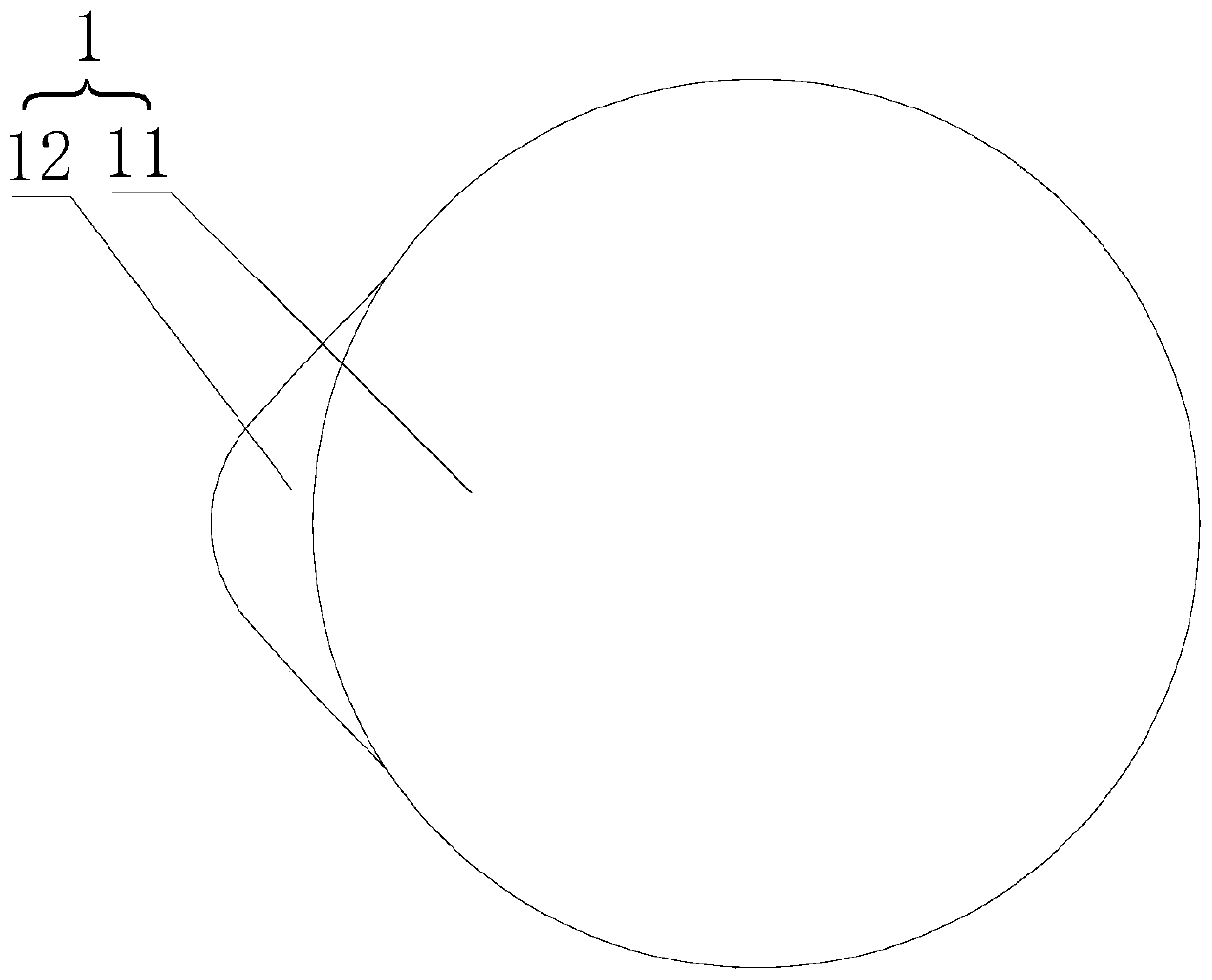

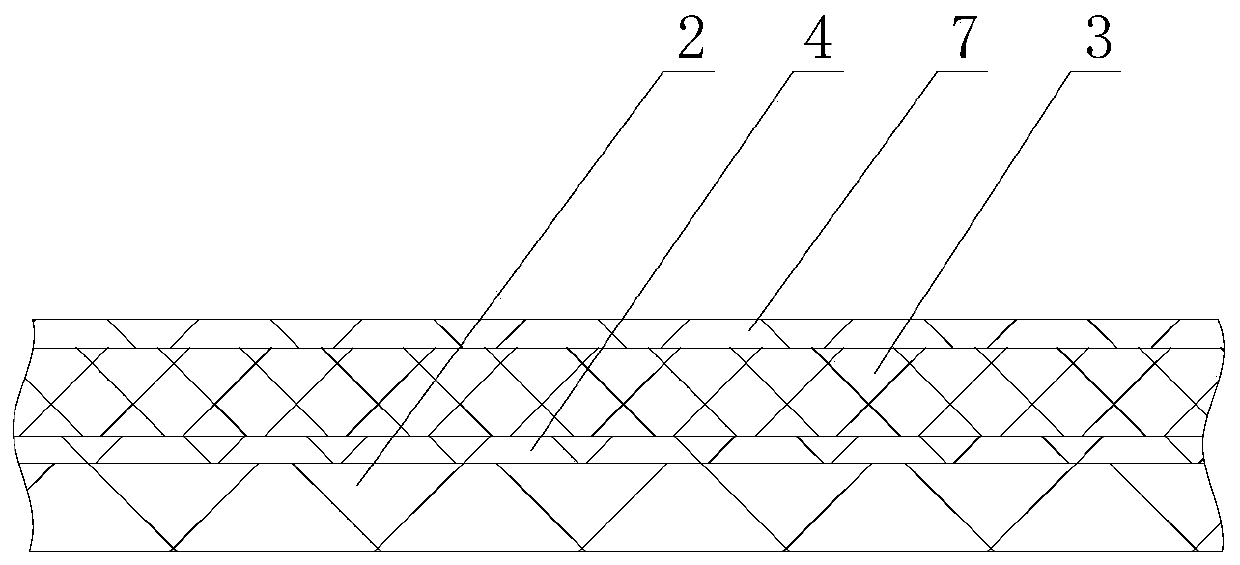

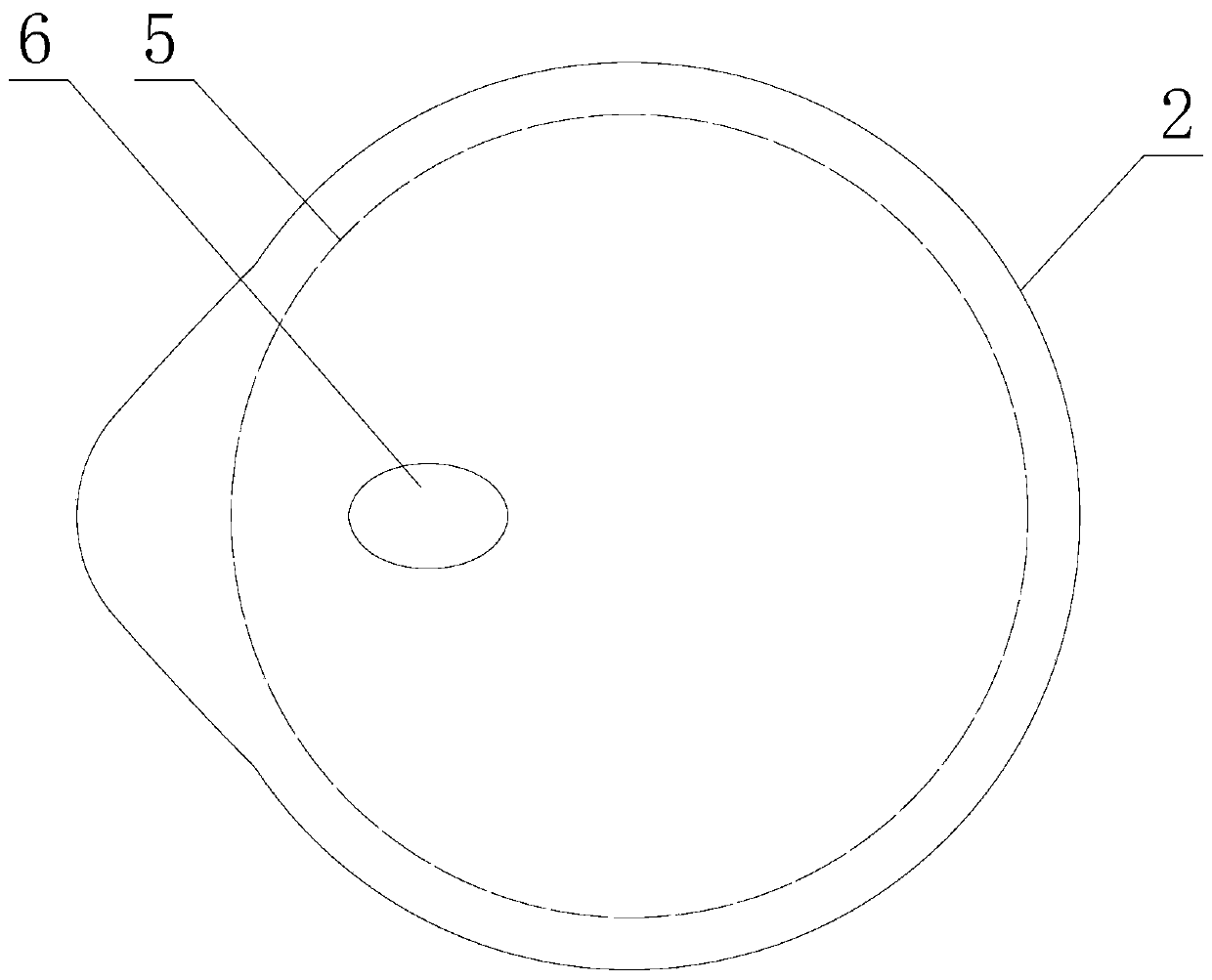

[0022] Such as figure 1 , figure 2 , image 3 As shown, a peelable sealing lidding film includes a film body 1, and the film body 1 includes a barrier layer 2 and a heat-sealing layer 3. The barrier layer in this embodiment adopts an AL layer, and also includes a barrier layer arranged on the barrier layer. An easy-peelable coating 4 between the layer 2 and the heat-sealing layer 3, the easy-peelable coating 4 is prepared by a mixture of nitrocellulose and polyurethane, the heat-sealing layer 3 is prepared by casting polypropylene, and The heat-sealing layer 3 is provided with a cutting line 5 where the barrier layer 2 and the heat-sealing layer 3 are delaminated when peeled off, and the heat-sealing layer 3 is also provided with a through hole 6 .

[0023] First, the connection between the barrier layer 2 and the heat-sealing layer 3 is realized through the easy-peelable coating 4. During use, when the barrier layer 2 is uncovered, due to the effect of the cutting line 5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com