Cardanol-aromatic diamine type benzoxazine flexibilizer as well as preparation method and purposes thereof

An aromatic diamine type, benzoxazine technology, used in the field of modification and application, synthesis of thermosetting resins, can solve the problem of short gel time, decreased mechanical strength and heat resistance of cured products, short gelation time, etc. problem, to achieve the effect of inhibiting the formation of by-products of aldolamine condensation, inhibiting the condensation reaction between methylol groups, and improving the yield and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

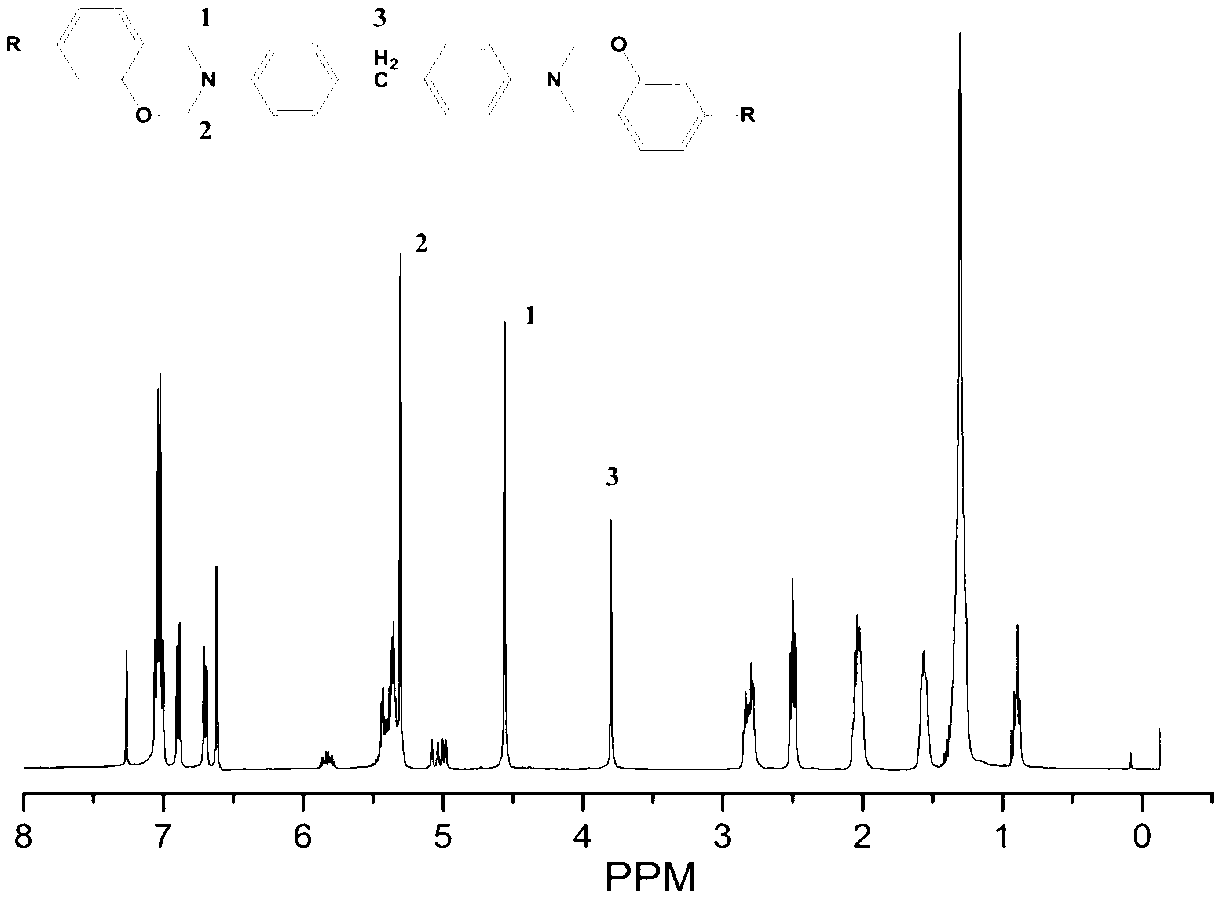

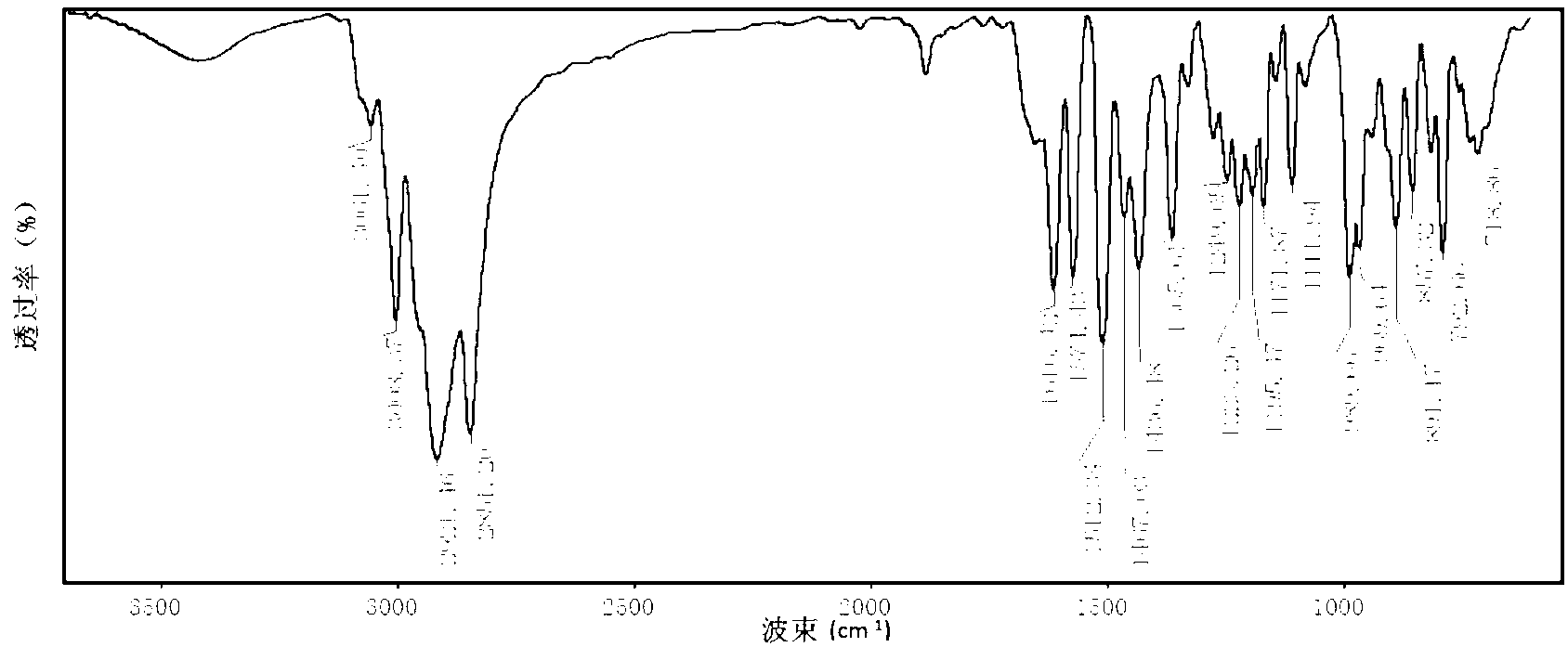

[0052] Add 66.5g (0.82mol) of 37% formaldehyde aqueous solution into a reaction vessel with a stirrer, a thermometer and a reflux condenser at 40°C, start stirring, add sodium hydroxide lye, and adjust the pH value to 7~ 8. Add 120g (0.4mol) of cardanol and 96g of toluene into the reactor and stir evenly. Then add 39.6g (0.2mol) diaminodiphenylmethane (DDM) and 20g ethanol into the reactor, react at 40°C for 30min, raise the temperature to 80°C for 4h, and obtain light yellow cardanol-diaminodiphenylmethane type Crude benzoxazine product solution.

[0053] The above crude product solution of benzoxazine was washed 4 times with an excessive amount of deionized water, dried by adding anhydrous sodium sulfate for 6 hours, filtered and allowed to stand for 24 hours to precipitate, filtered and dried to obtain light yellow powdered cardanol-aromatic diamine type benzene Oxazine toughening agent product, yield 95%.

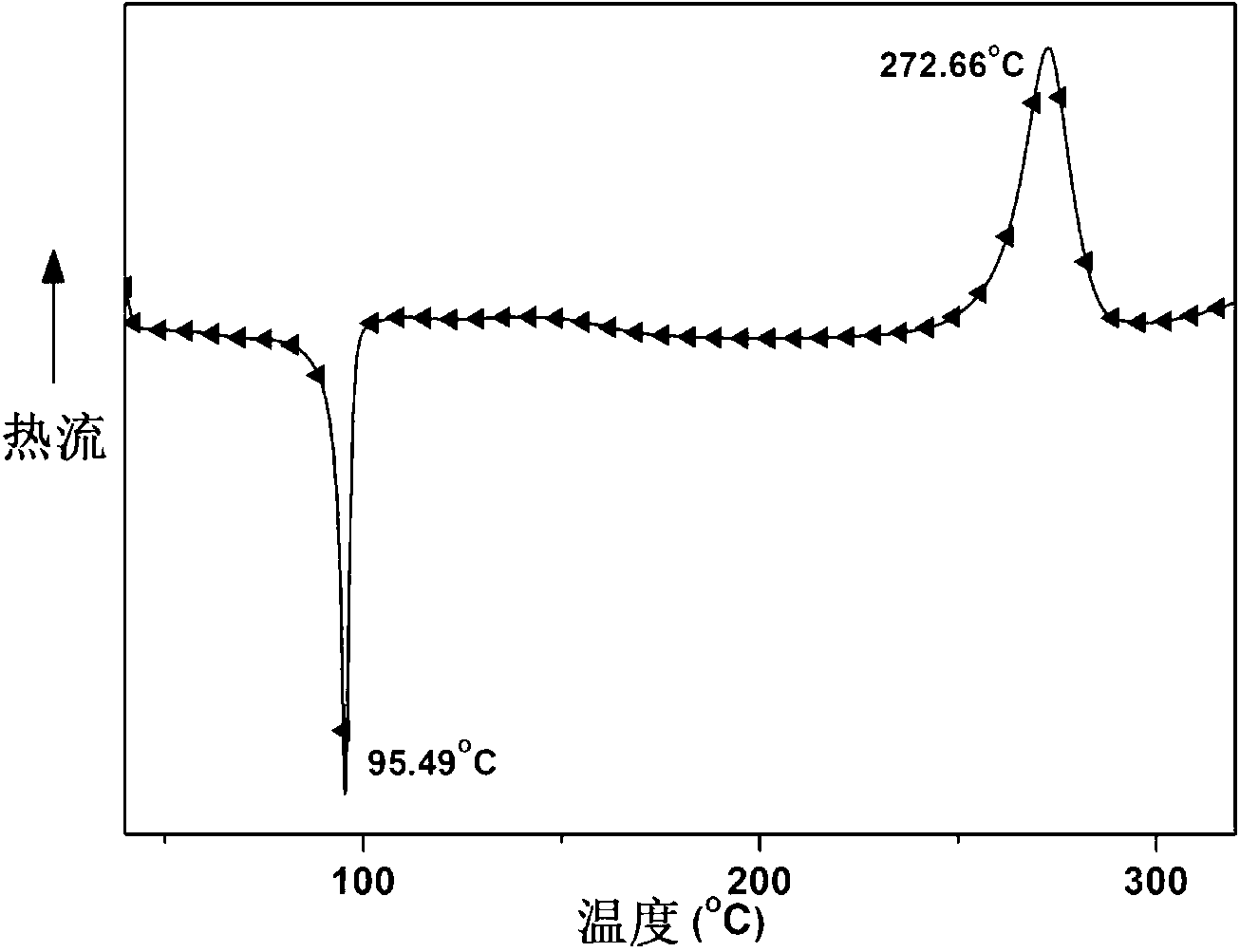

[0054] The melting point of the toughening agent powder measure...

Embodiment 2

[0056] Add 27 (0.9mol) of paraformaldehyde and 75g of water into a reaction vessel equipped with a stirrer, a thermometer and a reflux condenser, add ammonia water, adjust the pH value to 8-9, and stir at 50°C. After the paraformaldehyde was completely dissolved, 120g (0.4mol) of cardanol and 155g of dioxane were added into the reactor. Add 39.6g (0.2mol) diaminodiphenylmethane (DDM) and 15g methanol into the reactor, raise the temperature to 90°C and react for 4 hours to obtain a light yellow cardanol-diaminodiphenylmethane type benzoxazine crude product solution .

[0057] The above crude product solution of benzoxazine was washed twice with deionized water, added anhydrous sodium sulfate to dry for 12 hours, filtered and then stood still for 12 hours to precipitate, and filtered and dried to obtain light yellow powdered cardanol-aromatic diamine type benzoxazine The product of the oxazine toughening agent has a yield of 91% and a melting point of 95°C.

Embodiment 3

[0059] Add 68.6g (0.8mol) of 35% formaldehyde aqueous solution into a reaction vessel with a stirrer, a thermometer and a reflux condenser at 40°C, start stirring, add sodium hydroxide lye, and adjust the pH value to 7-8 . 120 g (0.4 mol) of cardanol and 120 g of toluene were added to the reactor. Add 40g (0.2mol) of diaminodiphenyl ether (DDE) and 20g of ethanol into the reactor, react at 40°C for 30min, raise the temperature to 80°C for 4h, and obtain light yellow cardanol-diaminodiphenyl ether type benzo Oxazine crude product solution.

[0060] The crude product solution of benzoxazine was washed twice with deionized water, dried over anhydrous sodium sulfate for 6 hours, and the solvent was removed in vacuo at 80°C to obtain a red liquid, and then a mixed solvent of 60 g of toluene and 34 g of acetone was added to obtain a reddish-brown transparent solution. After standing for 24 hours, the product of cardanol-aromatic diamine type benzoxazine toughening agent was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com