Cardanol modified phenolic aldehyde foam and preparation method thereof

A technology of phenolic foam and cardanol, which is applied in the field of phenolic foam and the preparation of the material, can solve the problems of difficult foaming of phenolic foam, high viscosity of phenolic resin, poor toughness of phenolic foam, etc., achieve low water absorption, improve toughness, reduce The effect of water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment one, this cardanol modified phenolic foam, it is made by the proportioning of following raw materials by weight:

[0049]Cardanol modified phenolic resin 100 parts;

[0050] Surfactant 4 parts;

[0051] Foaming agent 6 parts;

[0052] 15 parts of curing agent;

[0053] Each raw material proportioning of described cardanol modified phenolic resin is as follows by weight:

[0054] Cardanol 200 parts;

[0055] 1400 parts of phenol;

[0056] 140 parts of liquid formaldehyde;

[0057] 840 parts of paraformaldehyde;

[0058] 175 parts of methylol urea resin.

[0059]

Embodiment 2

[0060] Embodiment two, this cardanol modified phenolic foam, it is made by the following raw material proportioning by weight:

[0061] Cardanol modified phenolic resin 100 parts;

[0062] 7 parts of surfactant;

[0063] 10 parts of blowing agent;

[0064] 20 parts of curing agent;

[0065] Each raw material proportioning of described cardanol modified phenolic resin is as follows by weight:

[0066] Cardanol 350 parts;

[0067] 1700 parts of phenol;

[0068] 230 parts of liquid formaldehyde;

[0069] 870 parts of paraformaldehyde;

[0070] 200 parts of methylol urea resin.

[0071]

Embodiment 3

[0072] Embodiment three, this cardanol modified phenolic foam, it is made by the following raw material proportioning by weight:

[0073] Cardanol modified phenolic resin 100 parts;

[0074] 5 parts of surfactant;

[0075] Foaming agent 8 parts;

[0076] 17 parts of curing agent;

[0077] Each raw material proportioning of described cardanol modified phenolic resin is as follows by weight:

[0078] Cardanol 165 parts;

[0079] 1300 parts of phenol;

[0080] 130 parts of liquid formaldehyde;

[0081] 830 parts of paraformaldehyde;

[0082] 180 parts of methylol urea resin.

[0083]

[0084] The surfactant is Tween-80, Tween-60, EL-40 or PEG-25.

[0085] The blowing agent is any one or a mixture of n-pentane, cyclopentane or petroleum ether.

[0086] The blowing agent is composed of 50% n-pentane and 50% cyclopentane by mass percentage. .

[0087] The curing agent is any one or a mixture of p-toluenesulfonic acid, dimethylbenzenesulfonic acid, phenolsulfonic acid, ph...

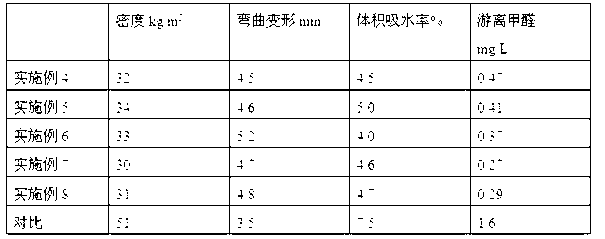

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strain | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com