Cardanol polyoxyethylene ether ammonium sulfate and preparation method thereof

A technology of cardanol polyoxyethylene ether and ester ammonium salt, which is applied in the direction of sulfuric acid ester preparation, organic chemistry, etc., can solve the problems of limitation, weak foaming power, and large skin irritation, and achieve simple equipment and low inorganic salt content Low, light color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

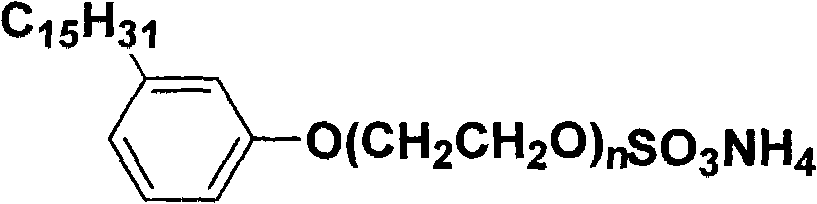

[0009] A cardanol polyoxyethylene ether sulfate ammonium salt, which has the following structural formula:

[0010]

[0011] Wherein, n=2-25.

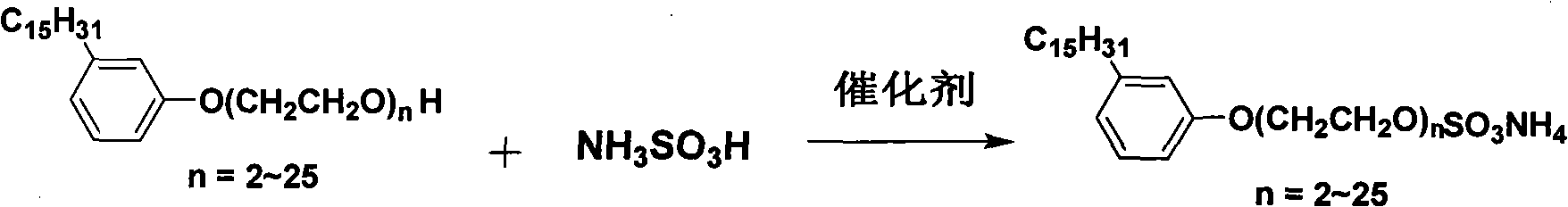

[0012] In the present invention, cardanol polyoxyethylene ether prepared from cardanol extracted from natural cashew nut shell is used as raw material, and then reacted with sulfamic acid to obtain cardanol polyoxyethylene ether sulfate ammonium salt with excellent performance , the mechanism is: sulfamic acid first forms SO 3 and NH 4 The complex compound is reacted with phenol ether to obtain cardanol polyoxyethylene ether sulfate ammonium salt. The equation of its reaction is as follows:

[0013]

[0014] The preparation method of polyoxyethylene cardanol sulfate ammonium salt is characterized in that polyoxyethylene cardanol is put into a reactor equipped with a stirrer, heated to 110-150°C, and fully stirred at a constant temperature Put in sulfamic acid and catalyst, react at constant temperature and under stirring for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com