Phosphorus-containing cardanol-base polyurethane prepolymer modified phenolic foam plastic and preparation method thereof

A polyurethane prepolymer and phenolic foam technology, which is applied in the field of biomass-based polyurethane prepolymer modified phenolic foam and its preparation, can solve the problems of low strength, poor toughness, and decreased flame retardancy of materials, and achieve low cost , Improve the effect of low elongation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

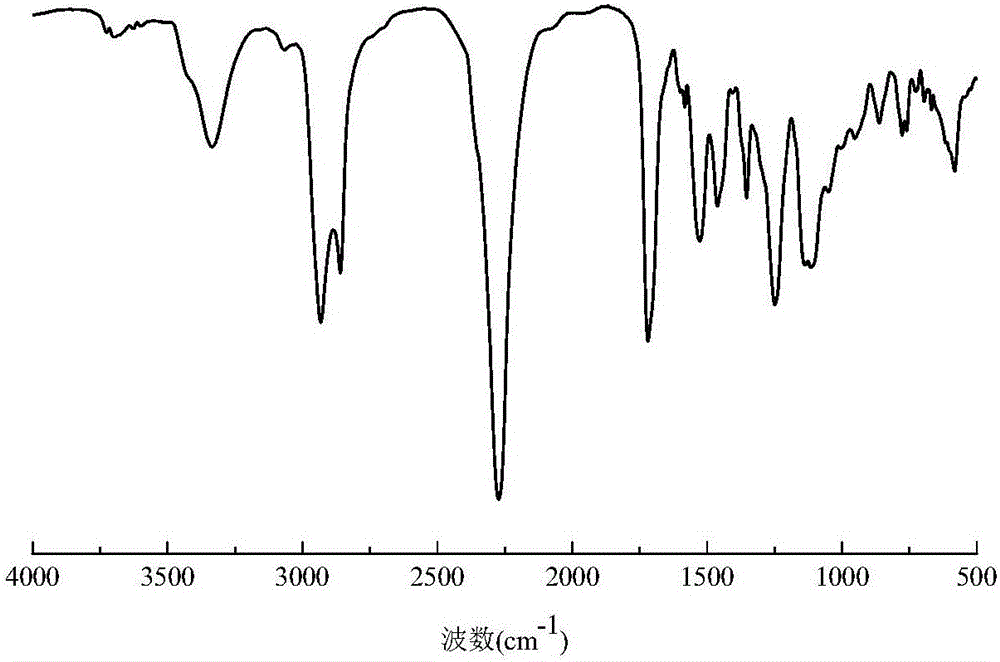

Image

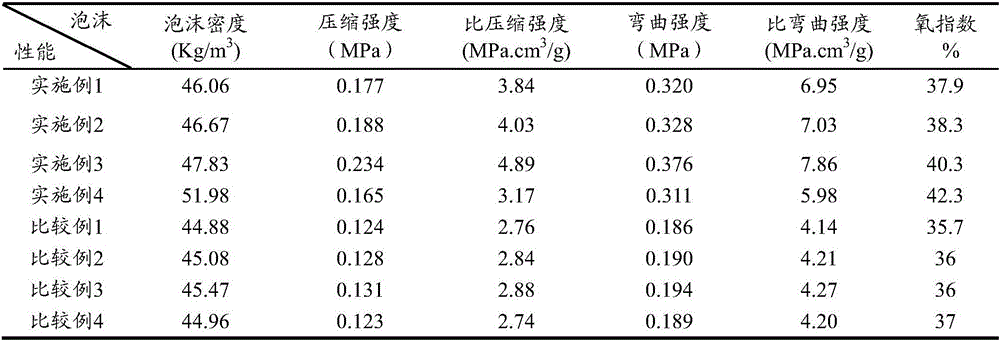

Examples

Embodiment 1

[0027] (1) Preparation of phosphorus-containing cardanol-based polyols: Add 26.4g of cardanol and 0.3g of anhydrous zinc chloride into the reaction flask, stir well and maintain the temperature at 90°C, add 11.7g of epichlorohydrin dropwise, After the addition is completed, react for 3 hours, then add 100 g of a 5% sodium hydroxide aqueous solution, heat up to 100° C., and react for 2 hours to obtain cardanol glycidyl ether; Hydrolyze at 100°C for 10 hours; extract the reactant with ether, wash with aqueous sodium bicarbonate, dry over anhydrous magnesium sulfate, distill off the ether to obtain 28.7g of cardanol-based diol; cardanol-based diol in 4.6g formic acid, 30g In the presence of hydrogen peroxide, react at 0°C for 24 hours, extract the reactant with ethyl acetate, wash with water, dry over anhydrous sodium sulfate, and evaporate the ethyl acetate to obtain 30.3 g of epoxy cardanol-based dihydric alcohol; epoxy cardanol Based dihydric alcohol and 5.6g DOPO were reacted...

Embodiment 2

[0033] (1) Preparation of phosphorus-containing cardanol-based polyols: Add 40g of cardanol and 0.6g of anhydrous aluminum chloride into the reaction flask, stir well and maintain the temperature at 98°C, add 24.61g of epichlorohydrin dropwise, and add After completion of the reaction for 3 hours, then add 100 g of a 10% sodium hydroxide aqueous solution in mass concentration, heat up to 100° C., and react for 2 hours to obtain cardanol glycidyl ether; Hydrolyze at ℃ for 15 hours, extract the reactant with ether, wash with aqueous sodium bicarbonate, dry over anhydrous magnesium sulfate, distill off the ether to obtain 49.10 g of cardanol-based diol; Under the condition of existence, reacted at 4°C for 20h, the reactant was extracted with dichloromethane, washed with water, dried over anhydrous sodium sulfate, and distilled off the dichloromethane to obtain 50.11g of epoxy cardanol-based dihydric alcohol; epoxy cardanol-based Dihydric alcohol and 6.4g of diethyl phosphate were...

Embodiment 3

[0039] (1) Preparation of phosphorus-containing cardanol-based polyols: Add 25g of cardanol and 0.2g of anhydrous zinc chloride into the reaction flask, stir well and maintain the temperature at 95°C, add 12.34g of epichlorohydrin dropwise, and add After completion of the reaction for 3 hours, then add 150 g of a 3% sodium hydroxide aqueous solution with a mass concentration, heat up to 100° C., and react for 4 hours to obtain cardanol glycidyl ether; Hydrolyze at ℃ for 10 hours, extract the reactant with ether, wash with aqueous sodium bicarbonate, dry over anhydrous magnesium sulfate, distill off the ether to obtain 28.12 g of cardanol-based diol; Under the condition of existence, react at 2°C for 24h, the reactant is extracted with chloroform, washed with water, dried over anhydrous sodium sulfate, and evaporated to remove chloroform to obtain 22.9g of epoxy cardanol-based diol; epoxy cardanol-based Dihydric alcohol and 4.3g DOPO were reacted at 140°C for 3 hours in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com