Solvent-free cardanol epoxy heavy-duty antiseptic paint and method for producing the same

A technology of cardanol epoxy and cardanol epoxy resin, which is applied in the field of solvent-free cardanol epoxy heavy-duty anti-corrosion paint and its preparation, can solve the problems of oil resistance, paint film brittleness, heat resistance, etc., and increase flexibility , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

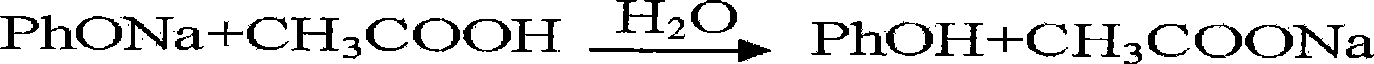

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: solvent-free cardanol epoxy heavy-duty anticorrosion paint, it consists of 40% nitrile modified epoxy resin, 35% cardanol epoxy curing agent, 8% ethylene glycol diglycidyl ether, 6 % talcum powder, 6% barium sulfate and 5% BZ202 wetting and dispersing agent; the above percentages are percentages by weight.

[0021] The above-mentioned nitrile modified epoxy resin is obtained by the following method: liquid nitrile rubber-26 (product of Lanzhou Petrochemical Company), epoxy resin (E-51) and catalyst benzoyl peroxide are mixed and stirred evenly, and reacted at 80 ℃ 3h to obtain a nitrile-modified epoxy resin; the weight ratio of the amount of nitrile rubber to epoxy resin is 1:2, and the amount of catalyst used is 3% of the total weight of nitrile rubber and epoxy resin.

[0022] The preparation method of above-mentioned solvent-free cardanol epoxy heavy-duty anti-corrosion paint, according to the proportioning of above-mentioned solvent-free cardanol epoxy...

Embodiment 2

[0023] Embodiment 2: solvent-free cardanol epoxy heavy-duty anticorrosion paint, it consists of 60% nitrile modified epoxy resin, 20% cardanol epoxy curing agent, 5% ethylene glycol diglycidyl ether, 10% talcum Powder and 5% BZ610 leveling agent; the above percentages are percentages by weight.

[0024] The above-mentioned nitrile-modified epoxy resin is obtained by the following method: mix and stir nitrile-butadiene rubber-40 (product of Lanzhou Petrochemical Company), epoxy resin (E-44) and azobisisobutyronitrile evenly, and react at 150°C for 3h , to obtain nitrile modified epoxy resin; the weight ratio of the amount of nitrile rubber to epoxy resin is 1:9, and the amount of catalyst is 1% of the total weight of nitrile rubber and epoxy resin.

[0025] The above-mentioned cardanol epoxy resin curing agent is obtained by the following method: add 75wt% cardanol xylene solution to the cardanol xylene solution weight 10wt% formaldehyde and stir evenly, then heat up to 90 ° C,...

Embodiment 3

[0027] Embodiment 3: solvent-free cardanol epoxy heavy-duty anticorrosion paint, it consists of 40% nitrile modified epoxy resin, 40% cardanol epoxy curing agent, 5% ethylene glycol diglycidyl ether, 10 % barium sulfate and 5% BZ401 defoamer; the above percentages are percentages by weight.

[0028] The above-mentioned nitrile-modified epoxy resin is obtained by the following method: mix and stir nitrile rubber 820, epoxy resin (E-51) and azobisisobutyronitrile evenly, and react at 100° C. for 1 hour to obtain nitrile-modified epoxy resin Resin; the weight ratio of the amount of nitrile rubber to epoxy resin is 1:5, and the amount of catalyst is 2% of the total weight of nitrile rubber and epoxy resin.

[0029] The above-mentioned cardanol epoxy resin curing agent is obtained by the following method: add 50wt% cardanol xylene solution to the cardanol xylene solution weight 30wt% formaldehyde and stir evenly, then heat up to 100°C, then add cardanol xylene solution weight 90% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com