Environment-friendly braking friction material and preparation method thereof

A brake friction material, an environment-friendly technology, applied in the field of brake friction materials and its preparation, can solve problems such as soil pollution, water resource hazards, unfavorable plant growth, etc., and achieve the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] Preparation of natural plant fibers

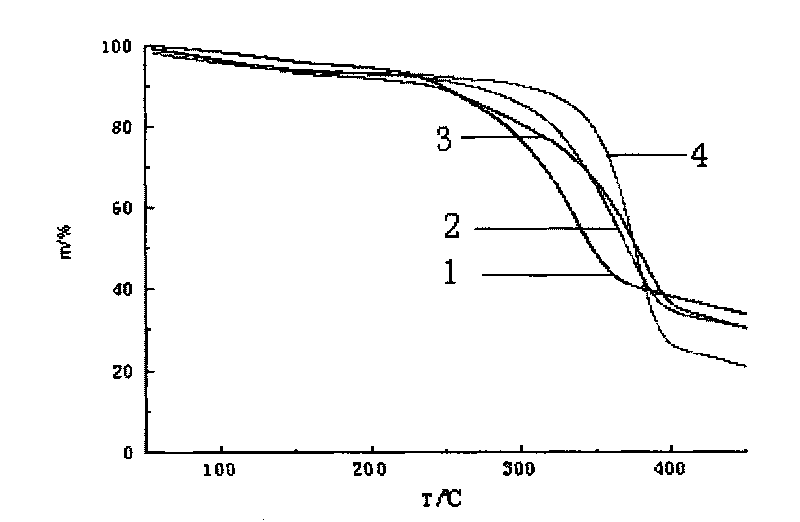

[0049]The natural plant fiber is washed with water, dried, chopped to 2-4mm, then soaked in 12% sodium hydroxide aqueous solution for 2-4h, and then the lye is washed away, and dried. Steam the chopped fibers with 1mol / L hydrochloric acid vapor for 30-60min, wash off the acid solution, and dry. Cook the chopped fiber with 2% sodium hydroxide solution at 80°C for 2-4 hours, then wash off the lye and dry it. The chopped fibers were steamed in a pressure cooker for 30 minutes and dried. High-pressure steam treatment is beneficial to the microfibrillation of natural plant fibers ( figure 1 ). Hydrochloric acid vapor treatment is beneficial to the length of natural plant fibers ( figure 2 ), overcome the shortcoming of shortening the length of natural plant fibers with conventional hydrochloric acid solution. Chemical (alkali, acid) treatment is beneficial to improve the thermal stability of natural plant fibers ( image 3 ).

[...

Embodiment 1

[0057] Preparation of environmentally friendly brake friction material containing flax

[0058] Formula (measured by volume fraction): flax fiber 9.0%, acicular limestone 28.8%, basalt fiber 8.0%, zircon 8.0%, barite 13.0%, vermiculite 5.0%, graphite 8.0%, cashew phenolic benzo Oxazine 5.6%, phenolic resin 14.6%. Measure all raw materials, granules and phenolic resin according to the formula, then stir in the high-speed mixer for 20-30 seconds, stop for 30-60 seconds, repeat 3-5 times, and control the total stirring time at 3-8 minutes to make the mixture evenly dispersed . Put the mixed material into a hot-press molding machine for hot-pressing. The hot-pressing temperature is 155-170° C., the pressure is 4-10 MPa, and the air is released 2-4 times. The hot-pressing time is 4-6 minutes in total. The molding is put into an oven for heat treatment, and kept at a temperature of 170-180° C. for 3-4 hours to obtain an environment-friendly braking friction material containing fla...

Embodiment 2

[0060] Preparation of environmentally friendly braking friction material containing ramie

[0061] Formula (measured by volume fraction): ramie fiber 9.0%, acicular limestone 28.8%, basalt fiber 8.0%, zircon 8.0%, barite 13.0%, vermiculite 5.0%, graphite 8.0%, cashew phenolic benzo Oxazine 5.6%, phenolic resin 14.6%. The preparation conditions of the brake friction material remain unchanged, and an environment-friendly brake friction material containing ramie is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com