Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

A technology of phenolic resin and phenolic resin solution, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems that the performance cannot meet the performance of high-performance copper clad laminates, and is not suitable for lead-free reflow soldering, so as to improve heat resistance and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

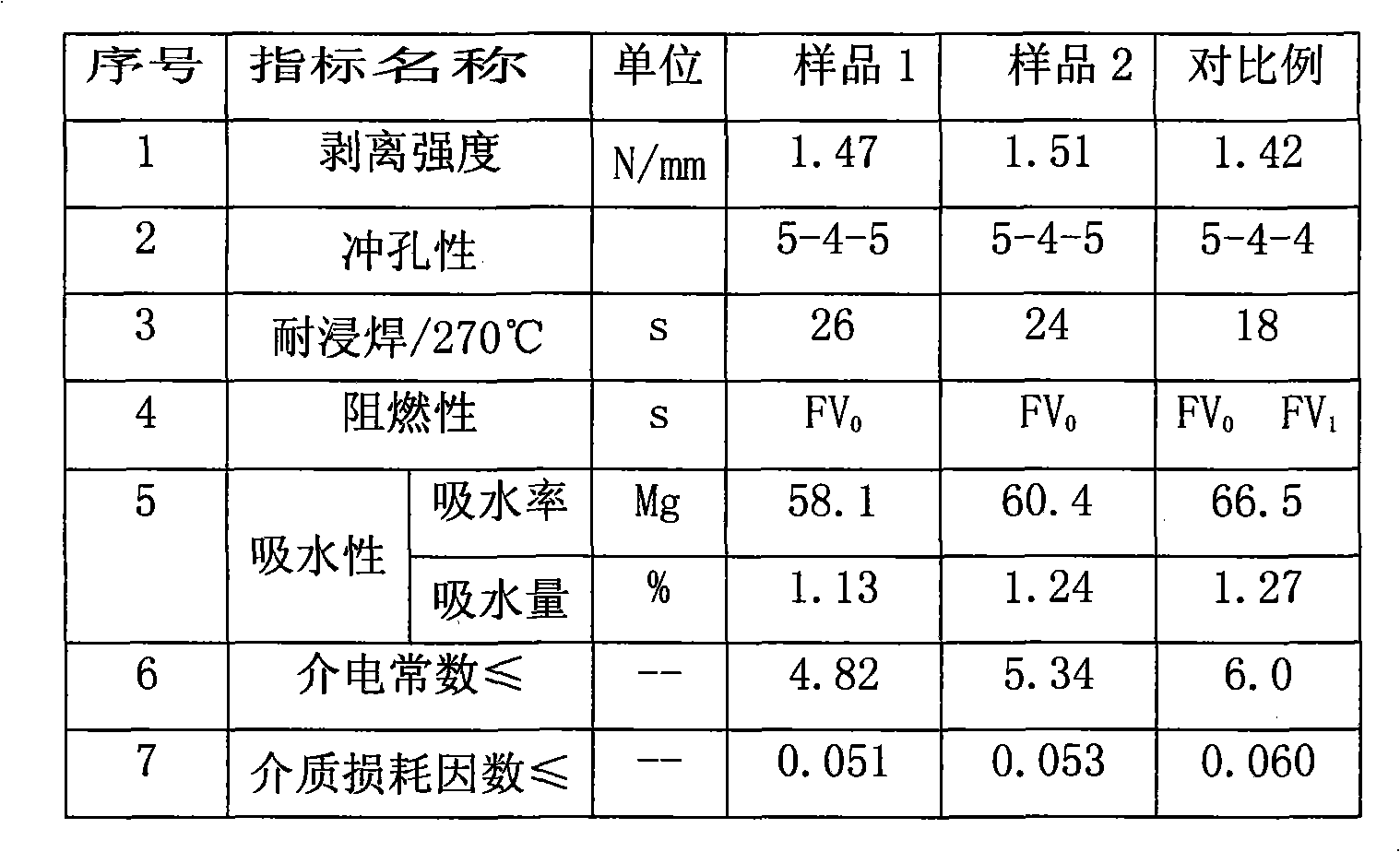

Examples

Embodiment

[0052] The cardanol-modified phenolic resin in the resin composition of the present embodiment uses cardanol, phenol, and tung oil as raw materials to carry out an alkylation reaction under the action of an acid catalyst to form an intermediate. Then add formaldehyde and nitrogen-containing phenolic resin, and carry out polymerization reaction under the action of alkali catalyst. According to the weight ratio, the amount of cardanol accounts for 30-35% of the amount of phenol and tung oil. The acid catalyst is an acid catalyst such as hydrochloric acid, sulfuric acid, oxalic acid, phosphoric acid, sulfonic acid, formic acid, etc., and the consumption accounts for 0.44-0.54% of the amount of cardanol, phenol and tung oil. Alkali catalysts are ammonia, trimethylamine, triethylamine, triethanolamine, ethylenediamine, etc., and their dosage accounts for 4.5-5.5% of the amount of cardanol, phenol and tung oil

[0053] If the amount of cardanol used is small, the viscosity of the p...

specific Embodiment 1

[0054] Put into a 1000ml three-necked flask in turn: 200g phenol, 150g tung oil, 105g cardanol, 2g acid catalyst, react at 95-105°C for 1-2 hours, take samples to measure viscosity, the index is 850-950CPS / 25°C . After passing the test, put in 140 grams of formaldehyde, 22 grams of nitrogen-containing phenolic resin and 20.5 grams of alkali catalyst for reaction, and keep the reaction at 85-95 °C for 1-2 hours, and vacuumize and dehydrate when the time is up; when the temperature rises to 80 °C-90 °C, take a sample to test the gel time, control the gel time to 70-80 seconds / 160±2 °C, and then stop dehydration. The resulting resin is a dark red transparent liquid, which is the cardanol-modified phenolic resin solution; add an appropriate amount of methanol to dissolve to obtain a modified phenolic resin with a solid content of 51-55%, and then use it to impregnate 126g / m2 The bleached wood pulp paper is dried to obtain a prepreg with a glue content of 50-51%. Combine 8 prepreg...

specific Embodiment 2

[0055] Put 300 grams of phenol, 200 grams of tung oil, 175 grams of cardanol, and 3.64 grams of acid catalyst into a 1000 ml three-necked flask, react at 95-105°C for 1-2 hours, take a sample to measure the viscosity, and the index is 850-950CPS / 25°C . Drop in 132 grams of formaldehyde, 34 grams of nitrogen-containing phenolic resin and 38 grams of alkali catalyst after passing the test, operate according to the technique of specific embodiment 1, obtain sample 2. Test according to the same standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com