Cardanol epoxy floor curing agent and preparation method thereof

A technology of cardanol epoxy flooring and epoxy flooring, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve problems such as poor impact resistance, insufficient toughness, easy cracking, etc., and achieve smoothness The effect of high strength, long pot life and wide range of mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

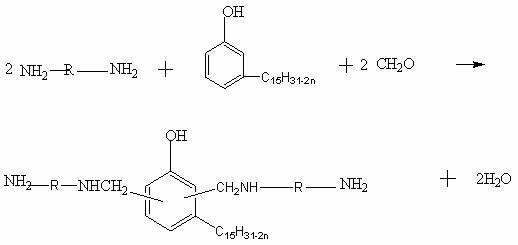

Method used

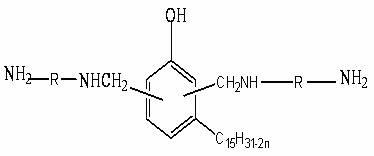

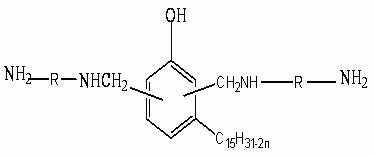

Image

Examples

example 1

[0031] On the 500ml four-necked flask, equipped with stirrer, condenser, water separator, thermometer, constant pressure burette, according to the molar ratio of cardanol:aminomethyltrimethylcyclohexylamine:formaldehyde=1:1.1:1, Add 150g of cardanol and 72g of aminomethyltrimethylcyclohexylamine, stir evenly, weigh 36.4g of formaldehyde with a mass concentration of 37% to 40%, and drop it into the reactor at a rate of 5 seconds / drop, and control the feeding temperature at 60°C , after stirring evenly, raise the temperature to 90°C, keep it warm for 3 hours, then carry out vacuum dehydration, the pressure is 0.0098Mpa, the dehydration temperature is 70°C, and the dehydration is until no liquid evaporates. The amine value is 256 mgKOH / g, and the viscosity is 4852 mPa·s.

example 2

[0033] The device is the same as that in Example 1. Add 150 g of cardanol at a molar ratio of cardanol: methylcyclopentadiamine: formaldehyde=1:1.5:1.5, and drop 49.8 g of formaldehyde with a mass concentration of 37% to 40% into the reactor. 7 seconds / drop, stir evenly, add 110.6g of methylcyclopentadiamine dropwise, control the feeding temperature at 50°C, stir evenly and then raise the temperature to 85°C, keep it warm for 5h, then carry out vacuum dehydration, the pressure is 0.0095Mpa, and the dehydration temperature is 60°C. Dehydrate until no liquid evaporates. The amine value is 338 mgKOH / g and the viscosity is 3813 mPa·s.

example 3

[0035] The device is the same as that in Example 1, with a molar ratio of cardanol: 1,2-cyclohexanediamine: formaldehyde=1:1.2:1.3, adding 150 g of cardanol and 78 g of 1,2-cyclohexanediamine, stirring evenly, and weighing the mass concentration as 38.4g of 37%-40% formaldehyde is dropped into the reactor, the dropping speed is 9 seconds / drop, the temperature is controlled at 50°C, after stirring evenly, the temperature is raised to 80°C, kept for 3 hours, and then vacuum dehydration is carried out, the dehydration temperature is 80°C, and the pressure is 0.0095Mpa , dehydrate until no liquid evaporates. The amine value is 295 mgKOH / g, and the viscosity is 4274 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com