Sea buckthorn berry oil preparation method

A technology of seabuckthorn fruit oil and seabuckthorn fruit, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of oil quality impact, safety hazard, high cost, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

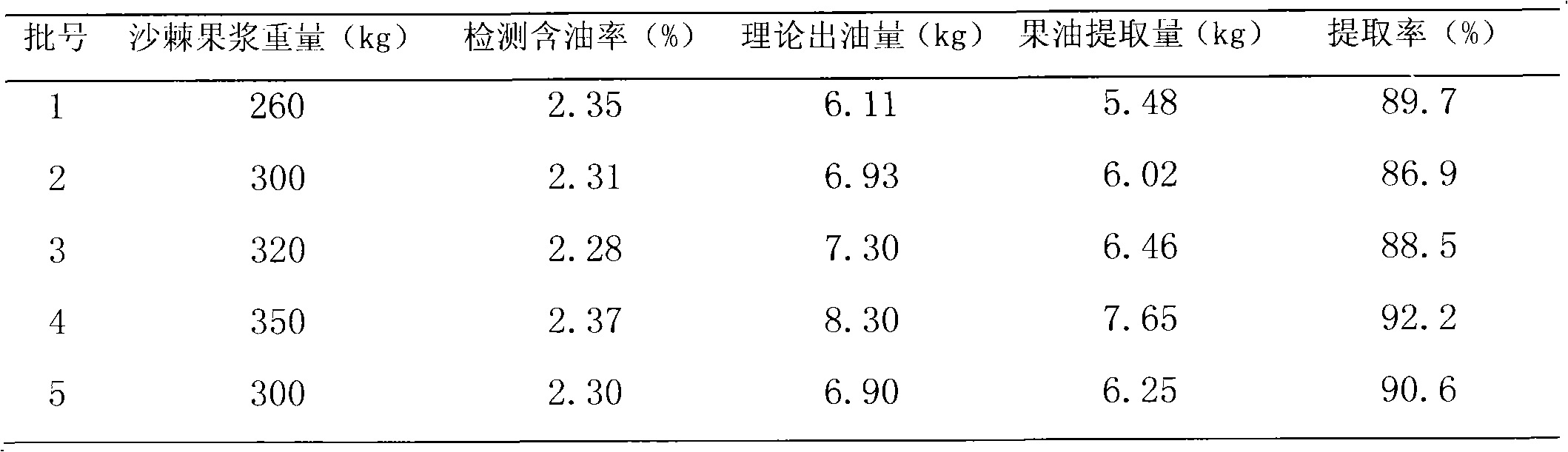

Examples

Embodiment 1

[0024] The preparation method of seabuckthorn fruit oil, concrete steps are as follows:

[0025] (1) Seabuckthorn fruit cleaning: put the seabuckthorn fruit in a washing machine, use 12°C-15°C drinking water that meets the national standard for drinking water to wash the seabuckthorn fruit, and drain the water for later use;

[0026] (2) Quick-freezing: Spread the drained sea-buckthorn fruit in the quick-freezing tank. The thickness of each quick-freezing tank is 16cm-20cm. The quick-freezing tank is cooled by liquid ammonia, and the quick-freezing temperature is adjusted to -25°C-28°C , the quick freezing time is 9 minutes to 12 minutes;

[0027] (3) Beating: put the quick-frozen seabuckthorn fruit in a beater, beat for 3-5 minutes, filter and take the seabuckthorn pulp;

[0028] (4) Pectinase hydrolysis: use pectinase produced by Novozymes Biotechnology Co., Ltd. with an enzyme activity of 200,000 IU / g to hydrolyze seabuckthorn pulp. The hydrolysis temperature is 55°C-60°C....

Embodiment 2

[0036] The preparation method of seabuckthorn fruit oil, concrete steps are as follows:

[0037] (1) Seabuckthorn fruit cleaning: put the seabuckthorn fruit in a washing machine, use 12°C-15°C drinking water that meets the national standard for drinking water to wash the seabuckthorn fruit, and drain the water for later use;

[0038] (2) Quick-freezing: Spread the drained sea-buckthorn fruit in the quick-freezing tank. The thickness of each quick-freezing tank is 16cm-20cm. The quick-freezing tank is cooled by liquid ammonia, and the quick-freezing temperature is adjusted to -25°C-28°C , the quick freezing time is 9 minutes to 12 minutes;

[0039] (3) Beating: put the quick-frozen seabuckthorn fruit in a beater, beat for 3-5 minutes, filter and take the seabuckthorn pulp;

[0040] (4) Pectinase hydrolysis: use pectinase produced by Novozymes Biotechnology Co., Ltd. with an enzyme activity of 200,000 IU / g to hydrolyze seabuckthorn pulp. The hydrolysis temperature is 55°C-60°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com