Mixed settler extractor

A technology of mixing clarification and extraction tank, which is applied in the direction of liquid solution solvent extraction, etc., can solve the problems of slow two-phase delamination, poor two-phase mixing effect, and reduced processing capacity of the extraction tank, so as to achieve good results and eliminate environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

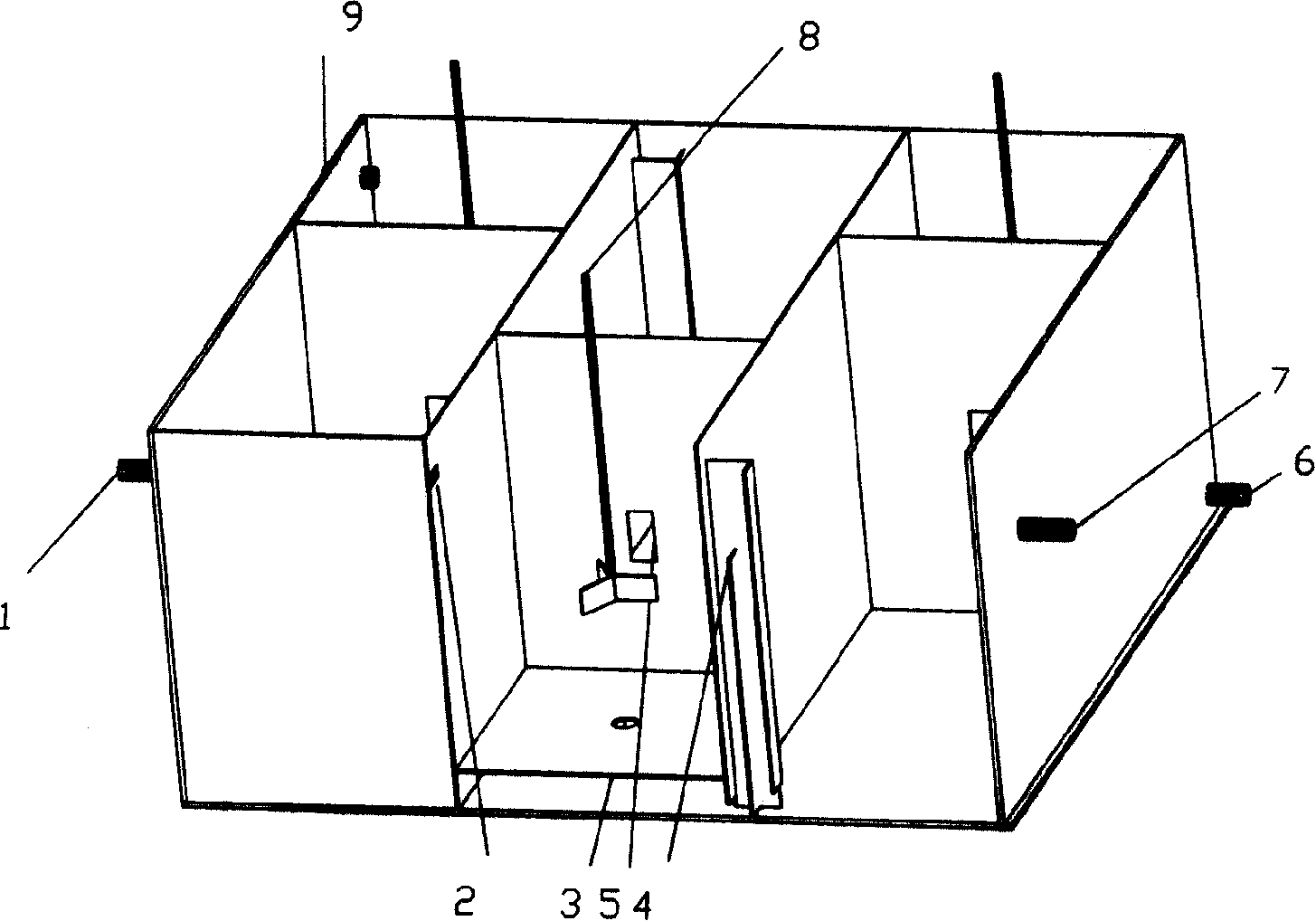

[0031]The extraction tank is prepared by PVC welding, and the 6-stage mixing and clarifying tank (on the same side as the mixing chamber) is combined into an extraction box as attached figure 2 . The effective size of the mixing chamber of the extraction tank is 1100mm×1100mm×1300mm; the clarification chamber is 2600mm×1100mm×1300mm. There is a φ30mm return pipe at the bottom of the clarification chamber to communicate with the mixing chamber.

[0032] The extraction box is used for back-extraction of the rare earth-containing organic phase. The organic extractant: 1.5mol / l P204 (kerosene dilution) flows into the first-stage mixing chamber at a rate of 250 liters / minute, and the back-extraction acid flows continuously into the sixth stage after metering. In the mixing chamber, the flow rate is 25 liters / minute, the two-phase flow ratio (O / A) is 10:1, the two-phase mixing ratio (O / A) in the mixing chamber is 2:1, and the temperature in the extraction tank is stable at 25°C. ...

Embodiment 2

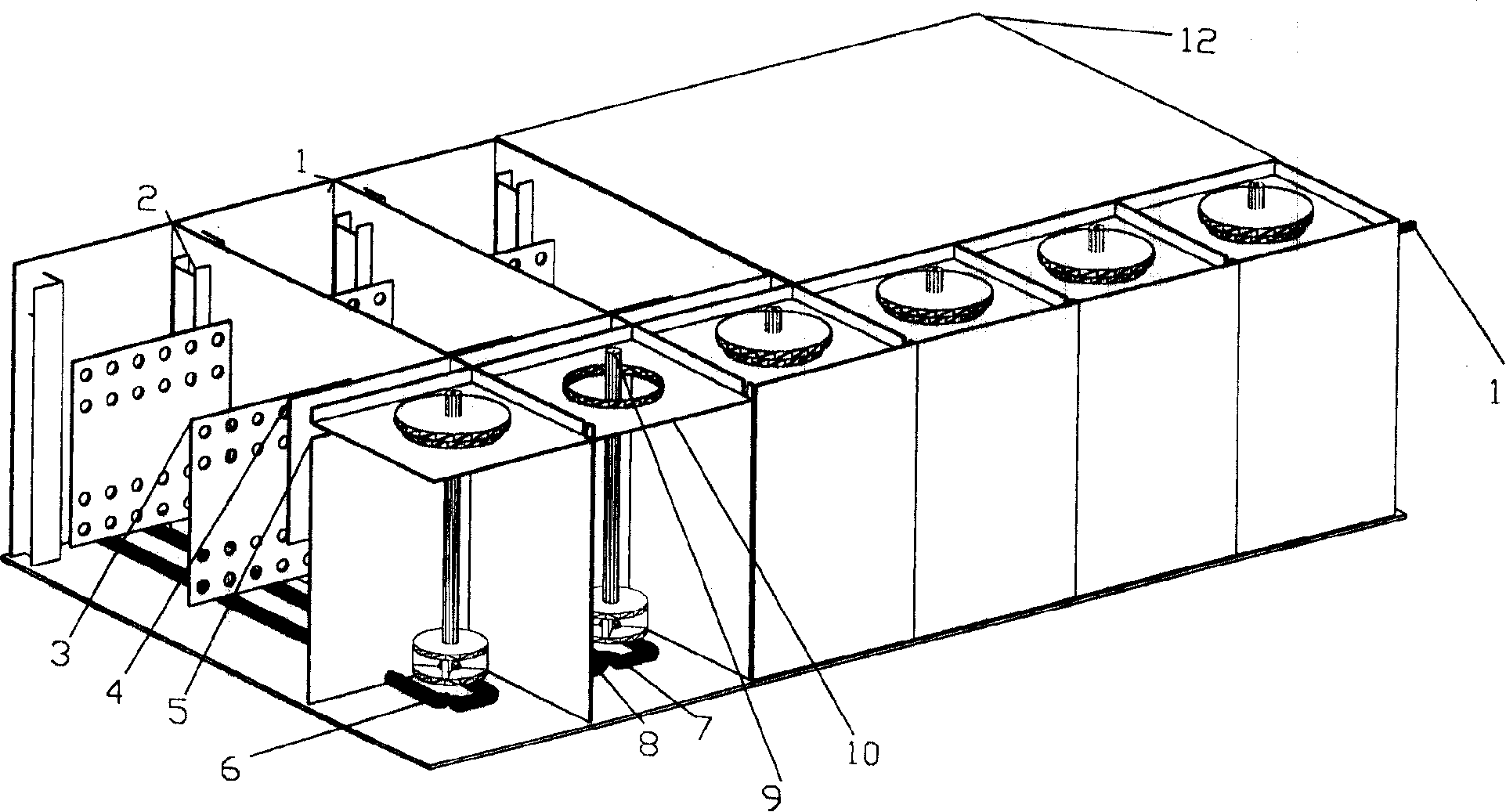

[0034] The extraction tank is made of glass fiber reinforced plastic, and the 8-stage mixing and clarifying tanks are arranged in a staggered manner to form an extraction box. image 3 . The effective size of the mixing chamber of the extraction tank is 800mm×800mm×1000mm; the clarification chamber is 2000mm×800mm×1000mm. The mixing chamber is equipped with 2 baffles, and two rows of φ30mm holes with a spacing of 100mm are arranged at each longitudinal end.

[0035] The extraction box is used for the extraction section of neodymium and samarium grouping of rare earth sulfuric acid solution. The rare earth sulfuric acid solution (33g / l) is continuously introduced into the 8th stage of the extraction box through a flowmeter, with a flow rate of 120 liters / min. Organic extractant: 1.0mol / l P204 (kerosene Dilution) flows into the first-stage mixing chamber at a speed of 40 liters / minute, the temperature in the extraction tank is 18° C., the mixed phase in the mixing chamber is a ...

Embodiment 3

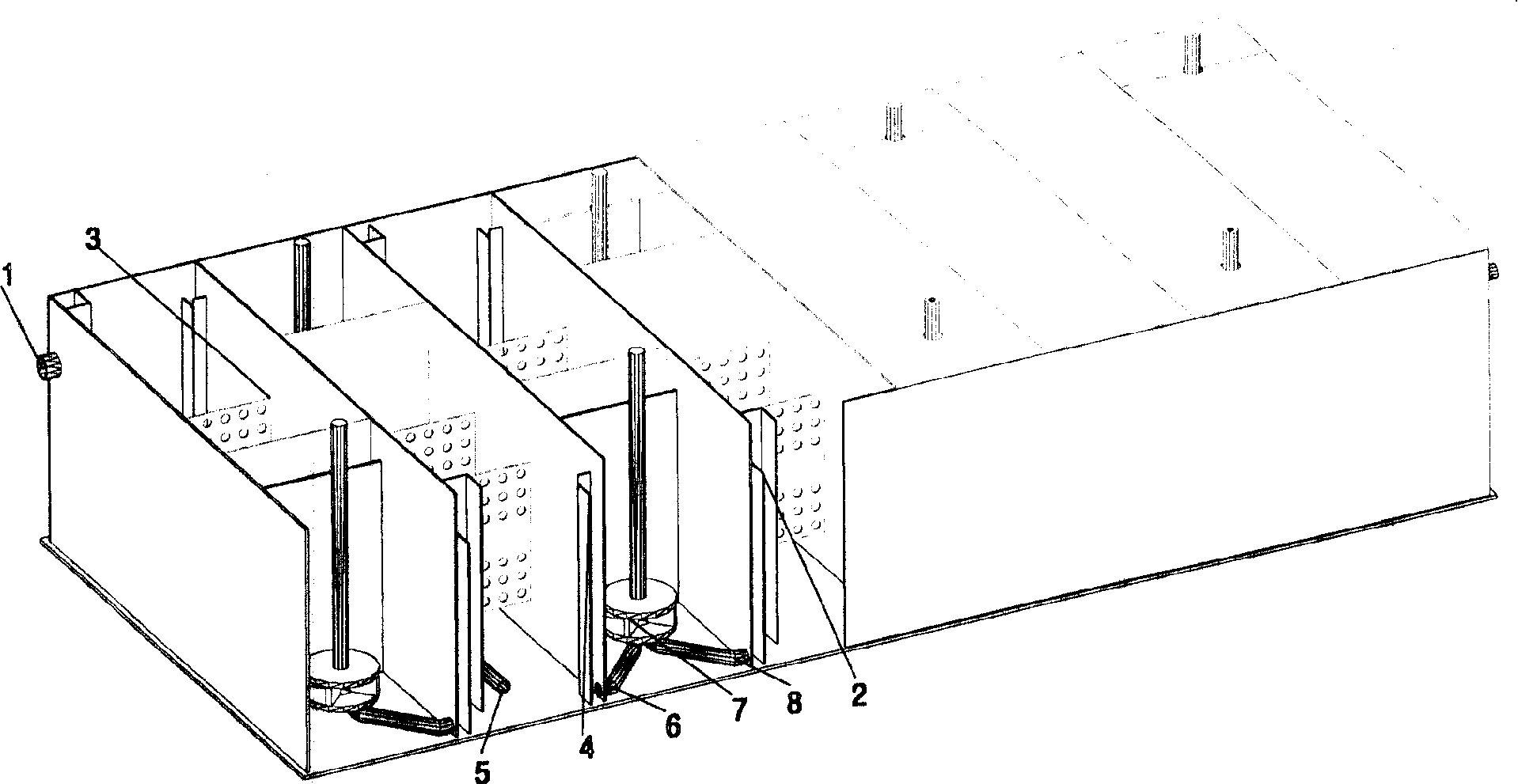

[0037] The extraction tank is prepared by welding 5mm stainless steel plate, the 20-stage mixing and clarification tank, and the 10-stage arrangement are combined into an extraction box as attached Figure 4 . The effective size of the mixing chamber of the extraction tank is 800mm×800mm×1000mm; the clarification chamber is 2000mm×800mm×1000mm. The bottom of the clarification chamber is equipped with a φ25mm return pipe to communicate with the mixing chamber, and the inner wall of the clarification chamber is equipped with a φ20mm stainless steel steam pipe for heating. The insulation layer is wrapped around the extraction box, and the upper part of the mixing chamber is equipped with a water-sealed cover.

[0038] The extraction box is used for solvent extraction of alkaline system, the flow ratio (O / A) of the organic phase and the aqueous phase is 35, the two-phase mixing ratio (O / A) of the mixing chamber is 3:1, and the temperature inside the box is 93°C. The temperature e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com