Patents

Literature

36results about How to "Good extraction and separation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extraction method of platinum in high-concentration platinum solution

ActiveCN103468967AShort processReduce processing timeProcess efficiency improvementChemistryHigh concentration

The invention relates to an extraction method of platinum in a high-concentration platinum solution. The method comprises the following steps of 1) diluting a high-concentration platinum waste dissolving solution with a hydrochloric acid solution with the concentration being 4mol / L; and 2) preparing the platinum solution on which the first-grade extraction is performed by an extraction agent in a dilution manner by taking normal octane as a diluent and N-normal-butyl valnoctamide as a solute and discharging a raffinate so as to obtain an extract containing the platinum. By utilizing the method, the concentration of the platinum in the material solution can be improved to 20g / L; the first-grade extraction rate E is greater than or equal to 99.5%; the technological process is reduced; and the treatment time is shortened. Thus, the method is efficient.

Owner:CHONGQING MATERIALS RES INST

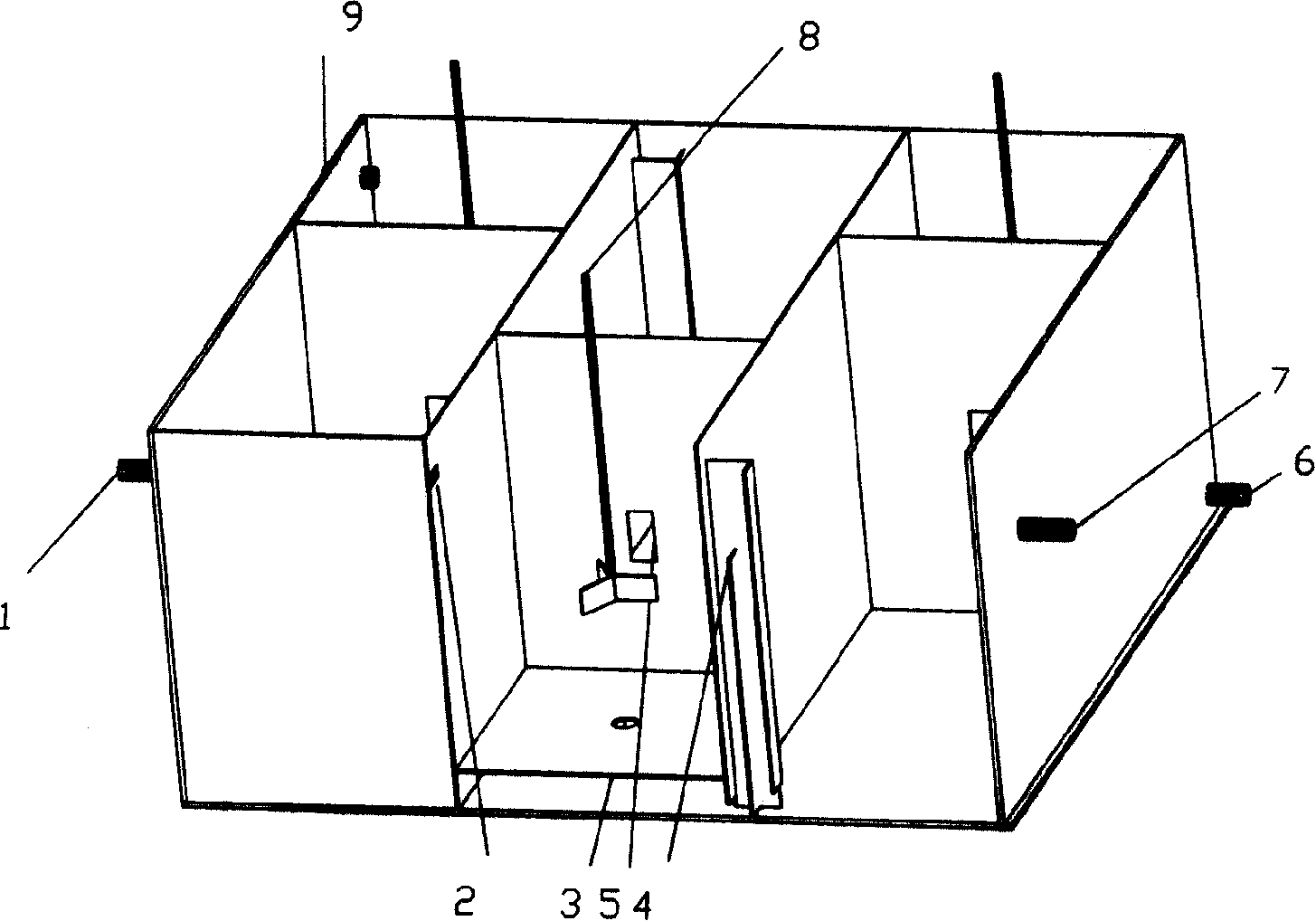

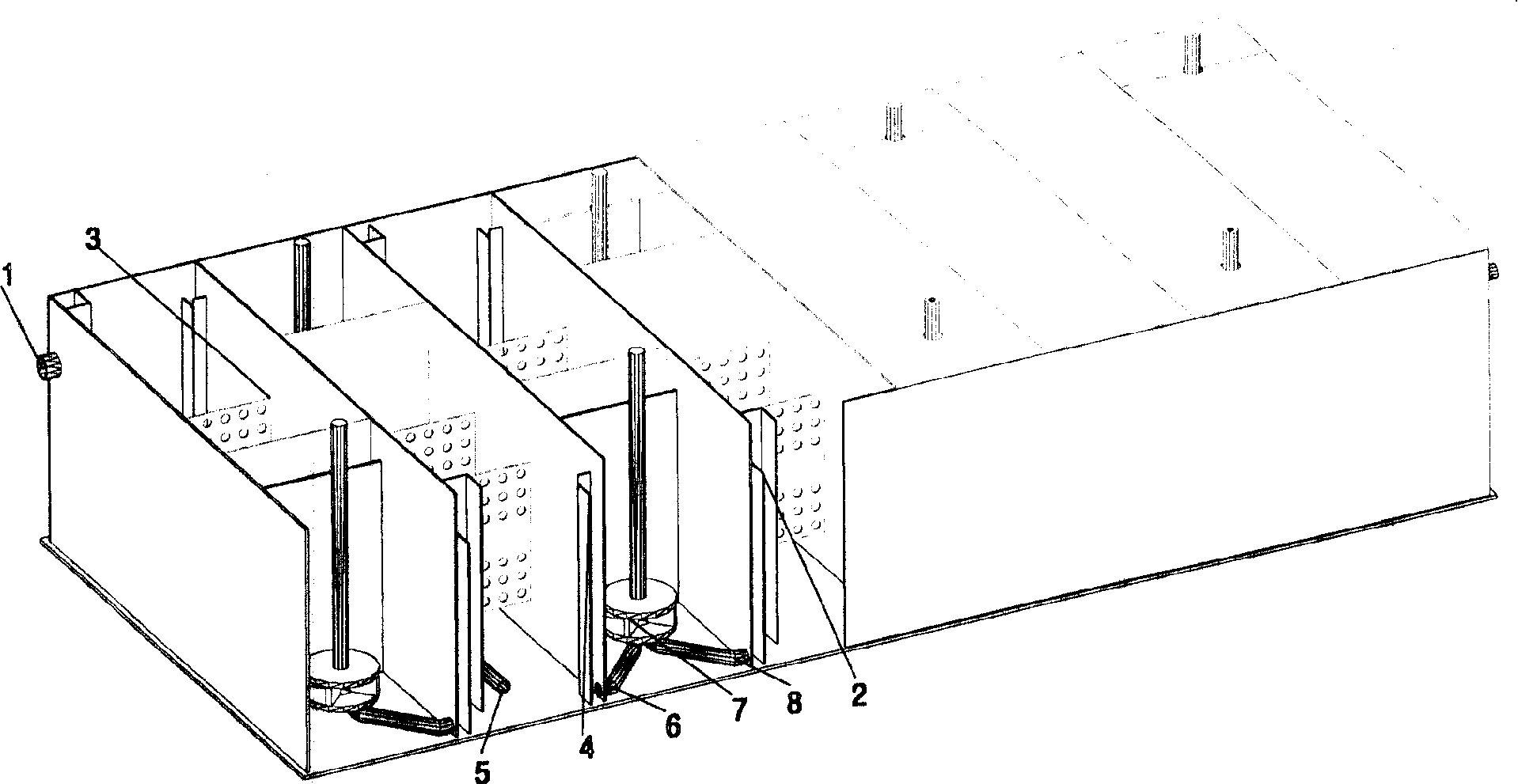

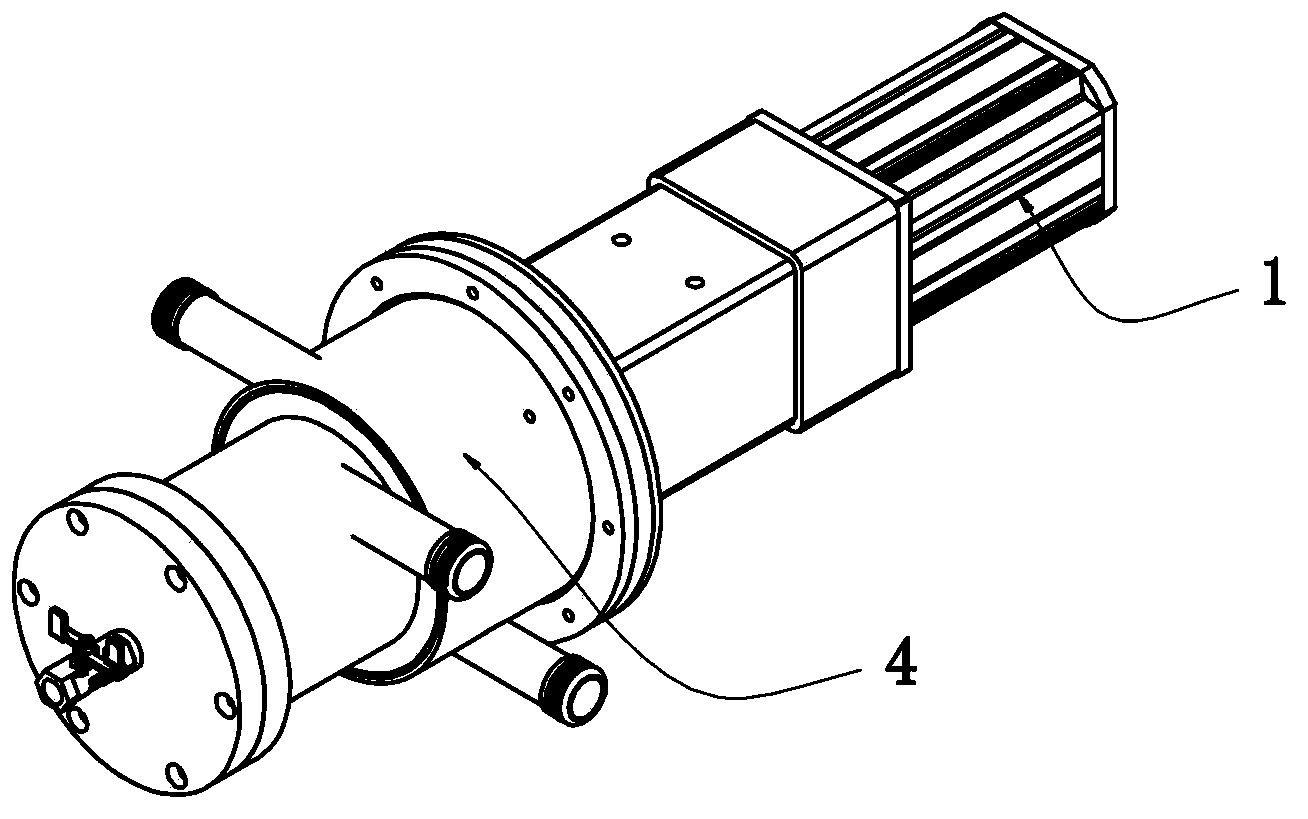

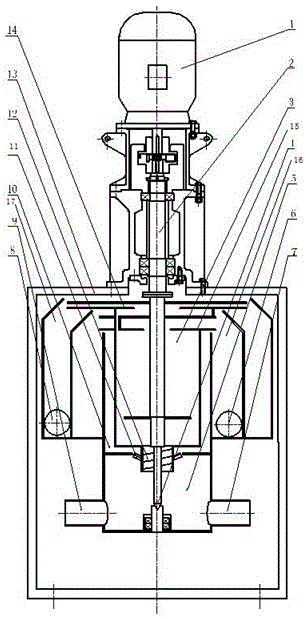

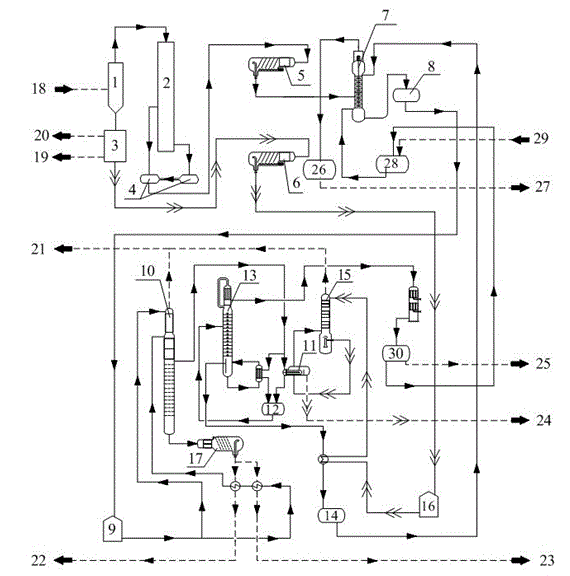

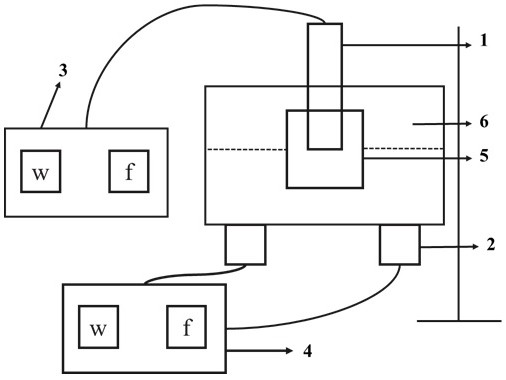

Mixed settler extractor

InactiveCN101219289AEliminate pollutionQuick layeringLiquid solutions solvent extractionSingle stagePhase ratio

The invention relates to a mixer settle extraction tank that is applicable to the extraction of high flow rate solvent, in particular to an extraction case combined by single-stage mixer settle extraction tanks. A two-phase mixer is stirred and driven by a turbine and the stirring has a pumping effect for two-phase fluid. Two phases are induced to a place below a stirring axial center by a diversion tube in a mixing chamber. The mixed phases are layered in a settling chamber, wherein, a light phase flows into a light phase box and enters a next stage mixing chamber through the diversion tube and a heavy phase gets across an overflow plate of a heavy phase box and enters a former stage mixing chamber and the two phases form an adverse current mode in a cascade stage device. The settling chamber is provided with a return line to be communicated with the mixing chamber to guarantee that the mixing phase ratio of the two phases in the mixing chamber is less than 4 when the flow rate of the two phases is high. A heat protection layer is coated around the extraction case, a cover board is arranged at the upper part and temperature in the tank body is constant. Water sealing is used at the top part of the mixing chamber of the extraction tank, thus organic gas evaporated from the extraction tank can be recovered.

Owner:GRIREM ADVANCED MATERIALS CO LTD

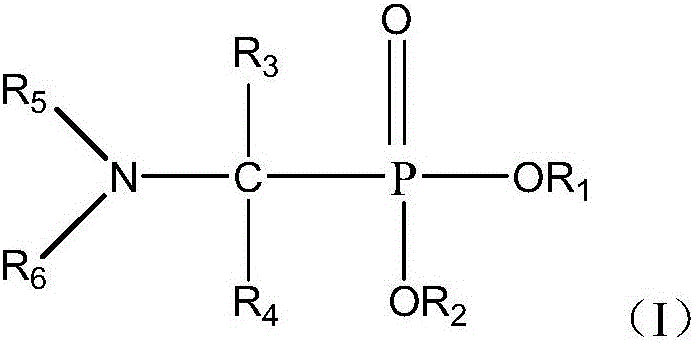

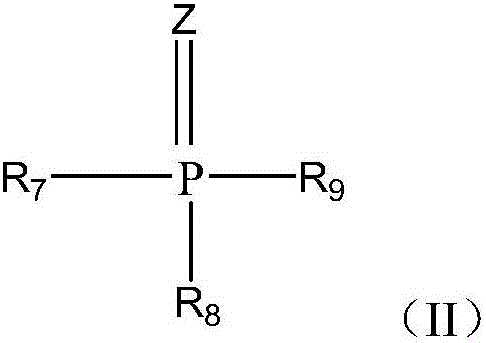

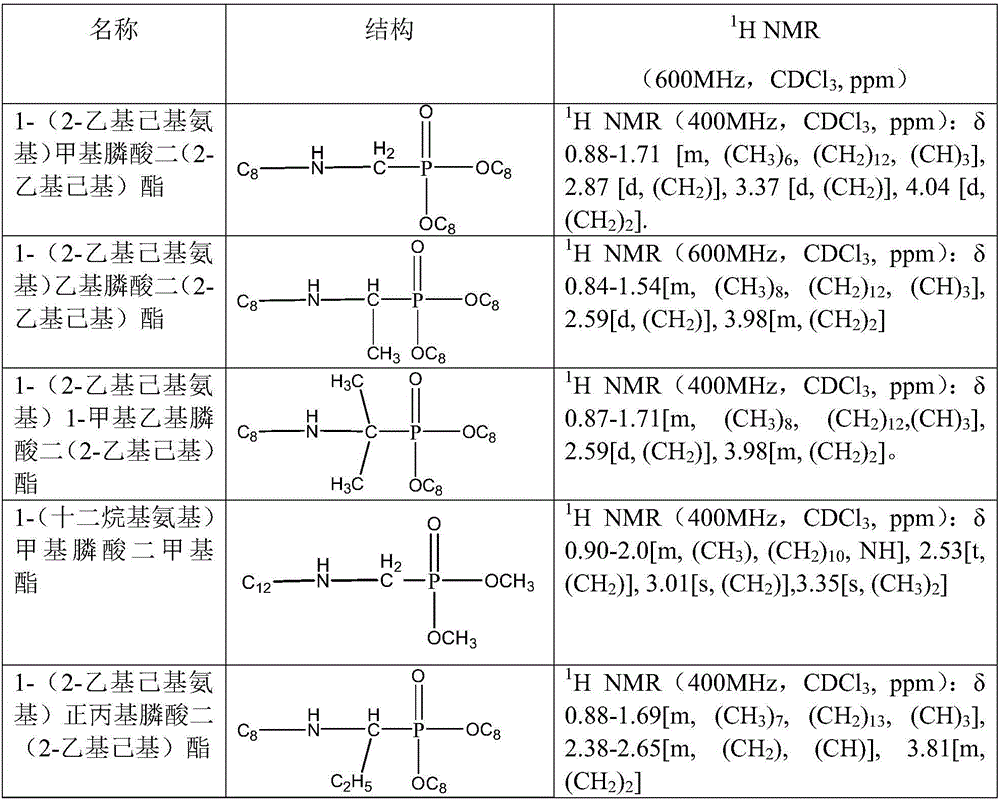

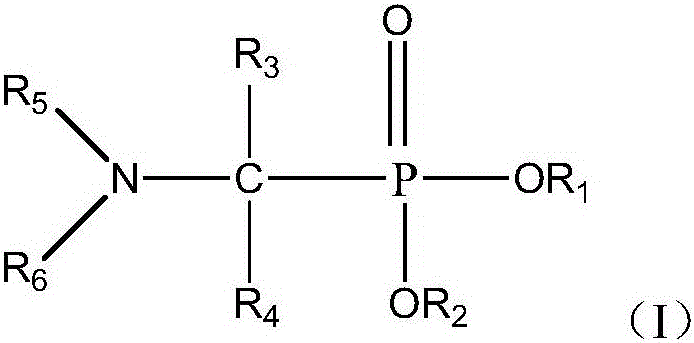

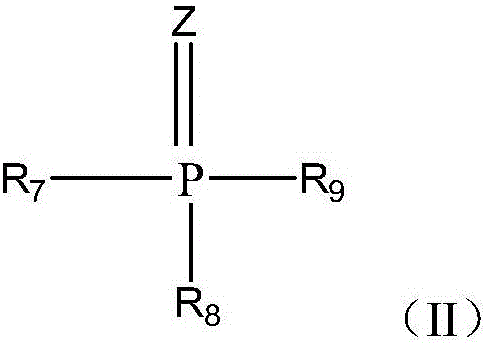

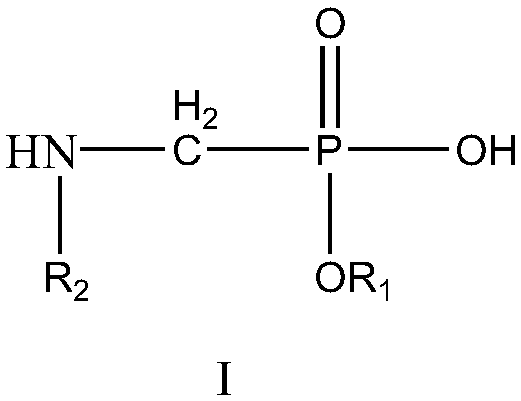

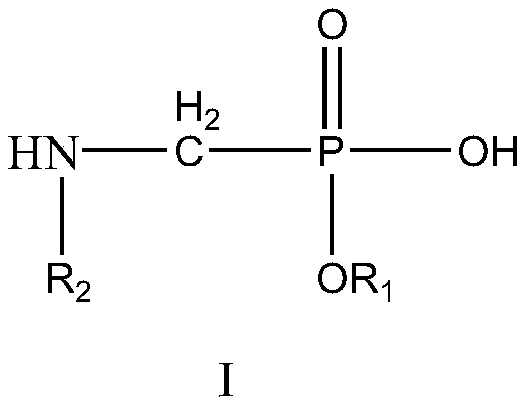

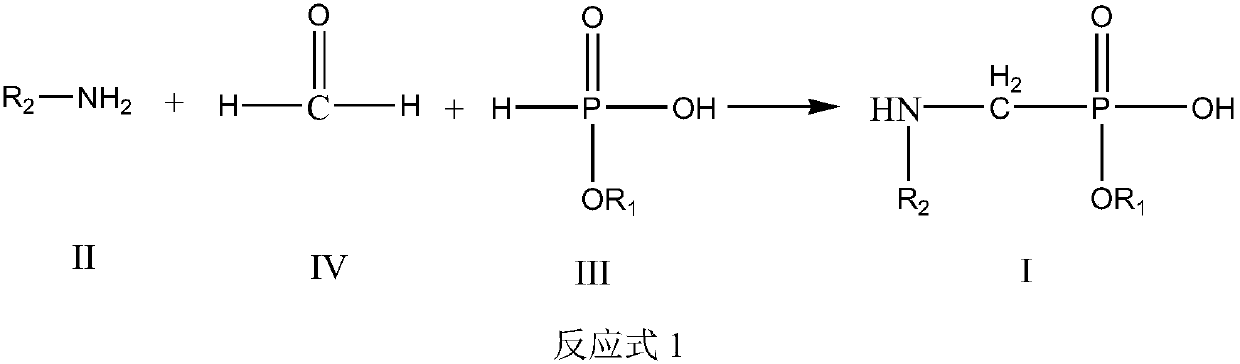

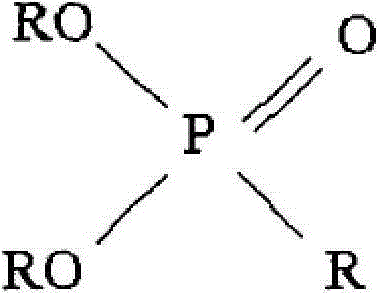

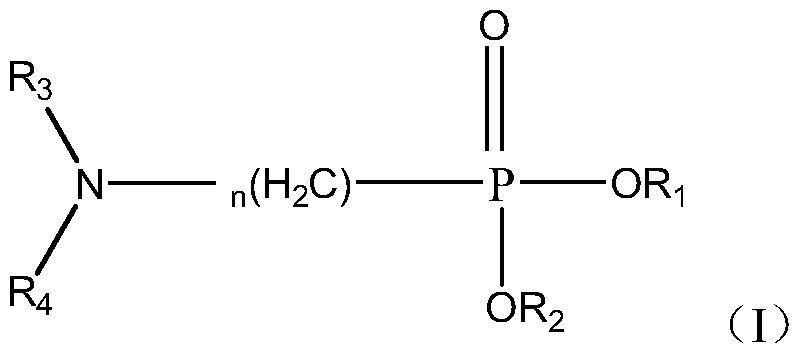

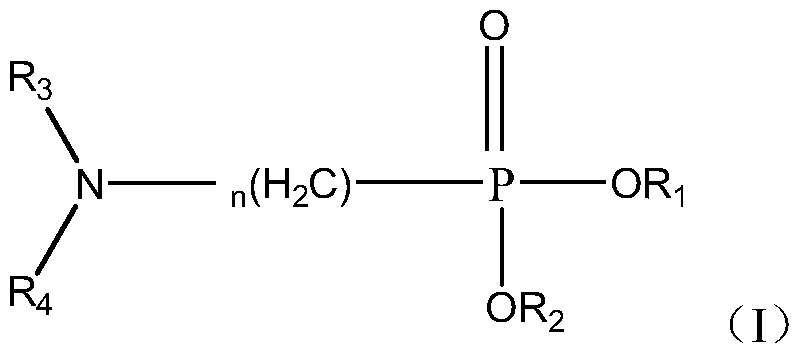

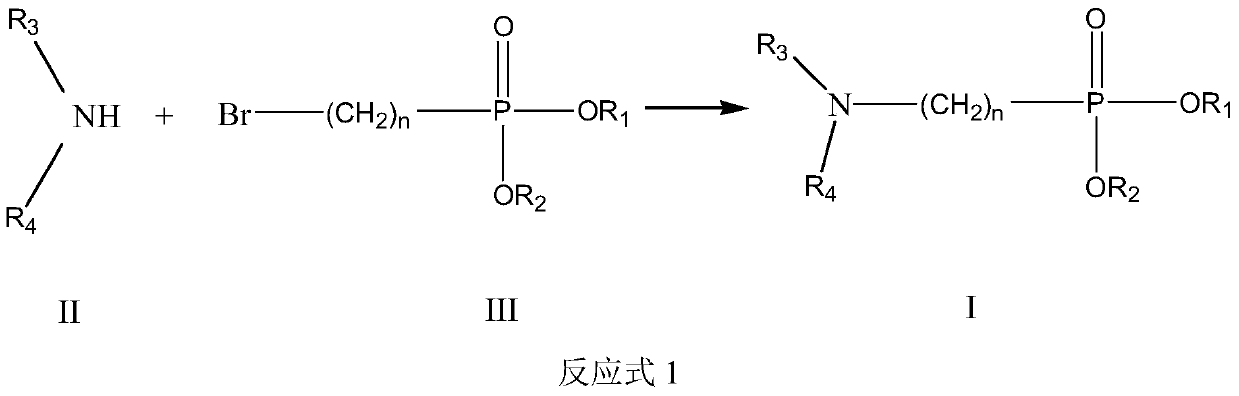

Application and method for extracting and separating uranium with amino-containing neutral phosphine extracting agent

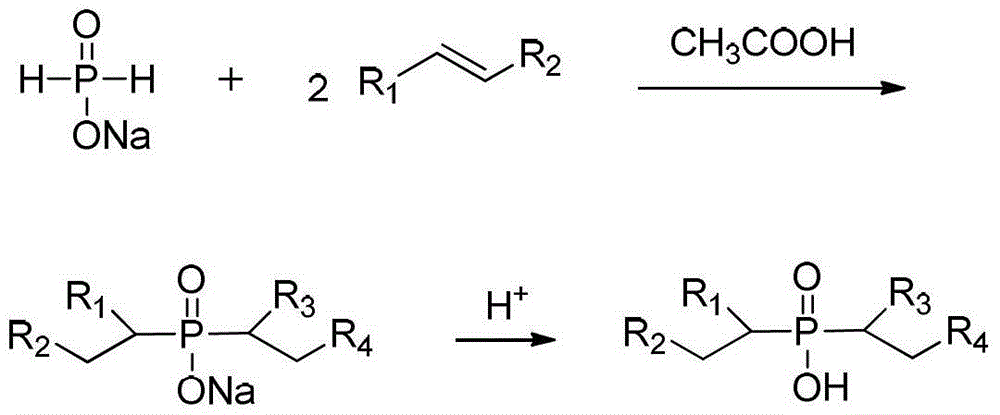

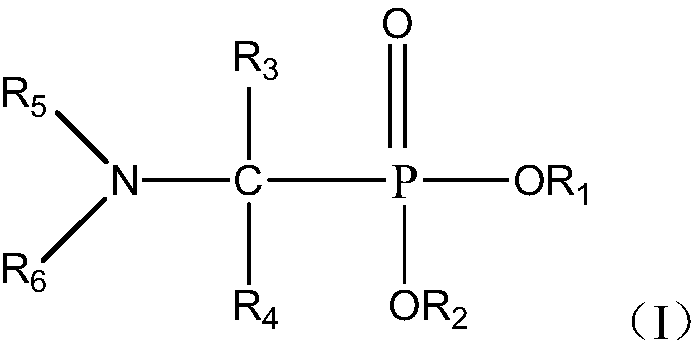

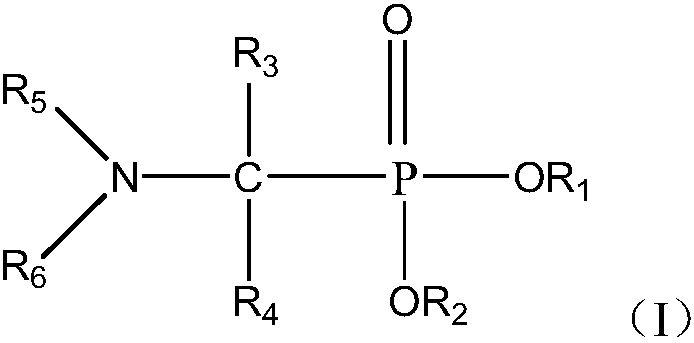

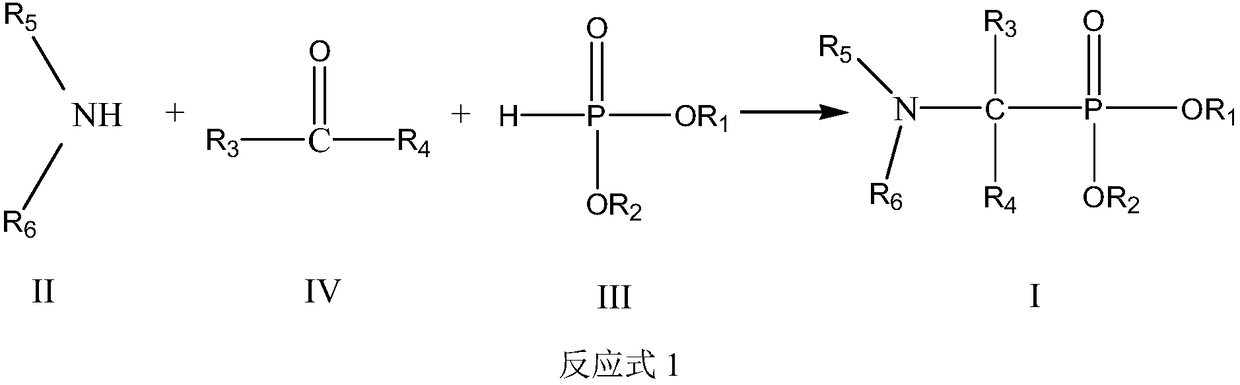

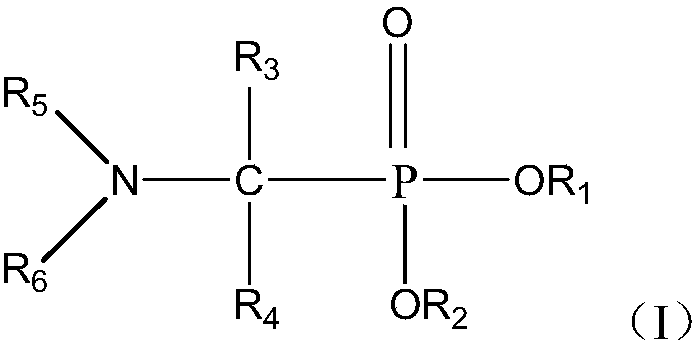

ActiveCN106521153AReduce the cost of extraction and separationGood extraction and separation abilityHydrogenSynthesis methods

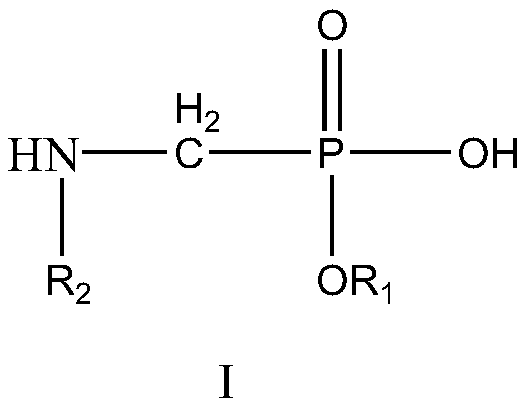

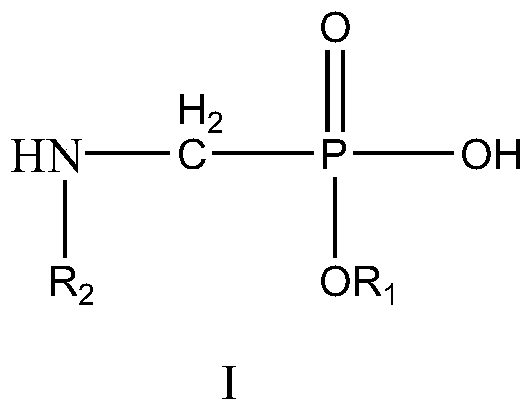

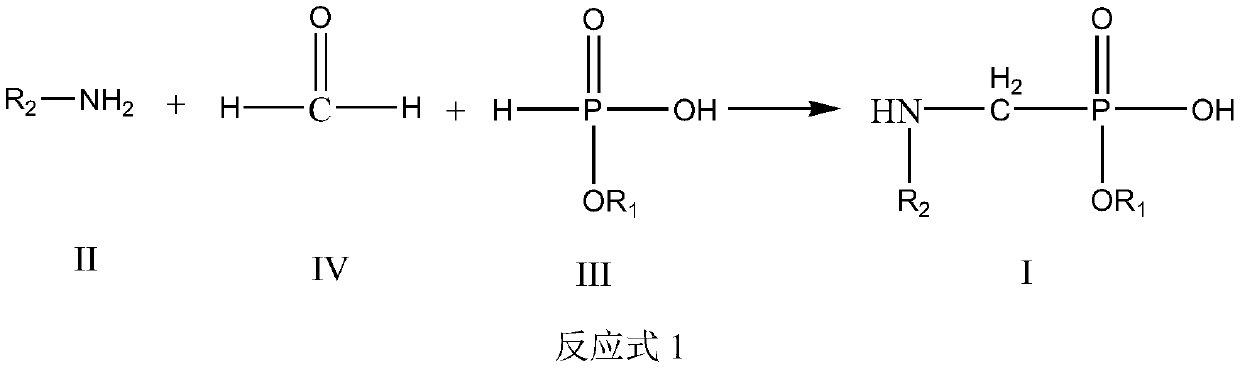

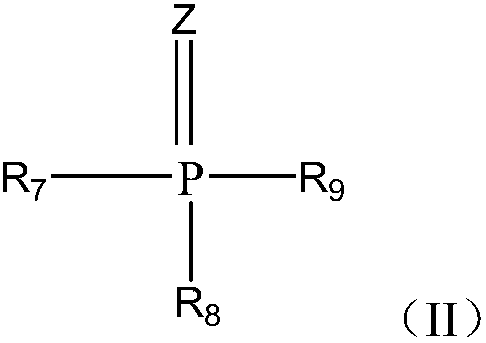

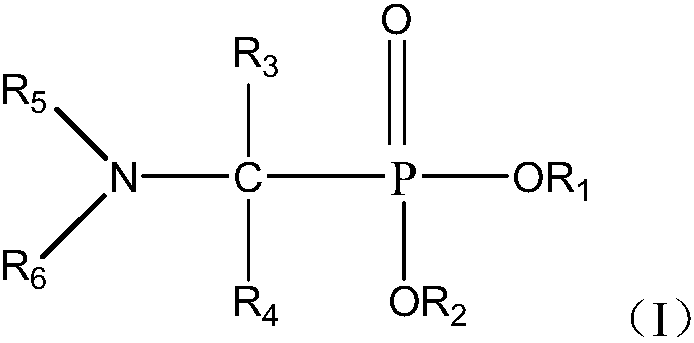

The invention relates to an application and method for extracting and separating uranium with an amino-containing neutral phosphine extracting agent. The formula is shown in the specification, wherein R1 and R2 are independently selected from C1-12 alkyl, R3 and R4 are independently selected from C1-5 alkyl and hydrogen, R5 and R6 are independently selected from C1-16 alkyl and hydrogen, and at most one of R5 and R6 is hydrogen. The amino-containing neutral phosphine extracting agent has good extracting and separating capacity to uranium in different acid media, the synthesis method is simple, chemical raw materials used for synthesis are simple and easy to obtain, cost is low, therefore, the extracting and separating cost of cerium can be effectively reduced, and high industrial application value is achieved. According to the method, liquid-liquid extraction and separation or solid-liquid extraction and separation is carried out on uranium in uranium-containing raw materials, the result shows that the purity of uranium obtained after extraction, washing and reextraction is 99% or above and the yield of uranium is 98% or above, and enrichment and purification of uranium are effectively achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Purpose and method of amido-contained neutral phosphine extracting agent for extracting and separating zirconium and/or hafnium

ActiveCN106521190AGood extraction and separation abilityReduce the cost of extraction and separationProcess efficiency improvementChemistryLiquid phase

The invention relates to a purpose and a method of an amido-contained neutral phosphine extracting agent for extracting and separating zirconium and / or hafnium. The amido-contained neutral phosphine extracting agent is expressed as the following formula I: FORMULA, wherein R1 and R2 are respectively and independently selected from C1-12 alkyl; R3 and R4 are respectively and independently selected from C1-3 alkyl and hydrogen; R5 and R6 are respectively and independently selected from C1-16 alkyl and hydrogen; and at most one of R5 and R6 is hydrogen. The amido-contained neutral phosphine extracting agent expressed as the formula I serves as a neutral phosphine extracting system for forming a main extracting agent to mix and extract with zirconium (IV) and / or hafnium (IV)-contained liquid; and then, such steps as extraction and reverse extraction are performed to respectively obtain zirconium or hafnium-contained solution or precipitates. The result shows that the purity of the finally obtained zirconium is higher than 99.99%, the content of hafnium in zirconium is lower than 80 ppm, in particular lower than 10 ppm; the purity of the obtained hafnium is higher than 99.0%, the content of zirconium in hafnium is lower than 0.1%; and the separation and the purification of zirconium and hafnium are effectively realized to achieve the use standards of atomic energy level zirconium and hafnium.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

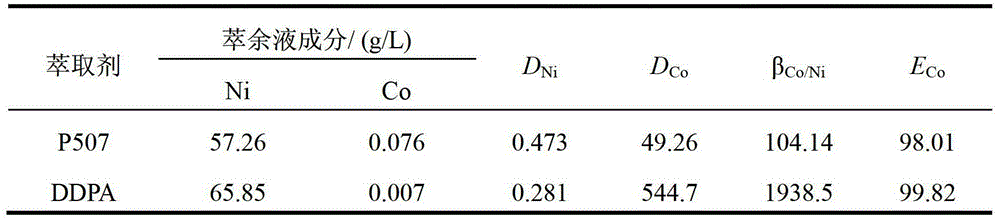

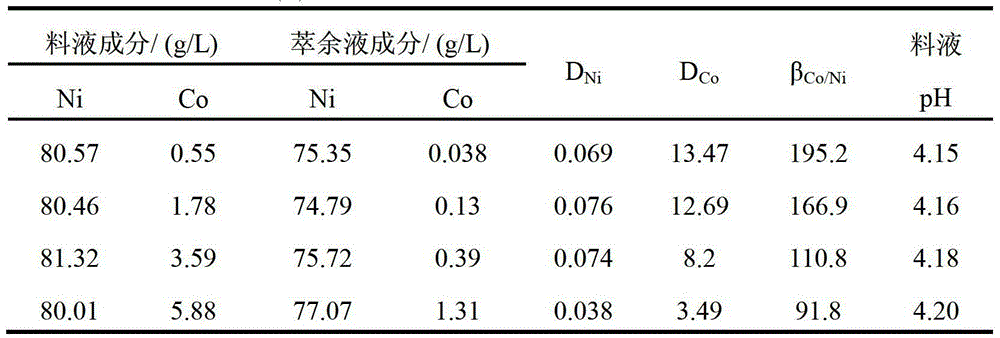

Application of amidogen-containing acid phosphine extraction agent to extraction and separation of cobalt and nickel, and method

The invention relates to application of an amidogen-containing acid phosphine extraction agent (please see the descriptions for the following general formula I) to extraction and separation of cobaltand nickel, and a method, wherein R1 is selected from C1-C12 alkyl groups, and R2 is selected from C1-C14 alkyl groups. The method comprises the step that the amidogen-containing acid phosphine extraction agent with the general formula I is used for extracting and separating the nickel from a feed liquid containing the cobalt and the nickel. The method can extract the nickel preferentially, then the nickel and the cobalt are separated, and thus the method has the remarkable advantage in low-nickel and high-cobalt feed liquid separation. Additionally, the amidogen-containing acid phosphine extraction agent adopted by the application and the method can separate the cobalt from the nickel in all different acid media, has the good extraction and separation capacity, is simple in synthetic method, low in cost, stable in property and easy to industrialize, and has high industrial application value.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

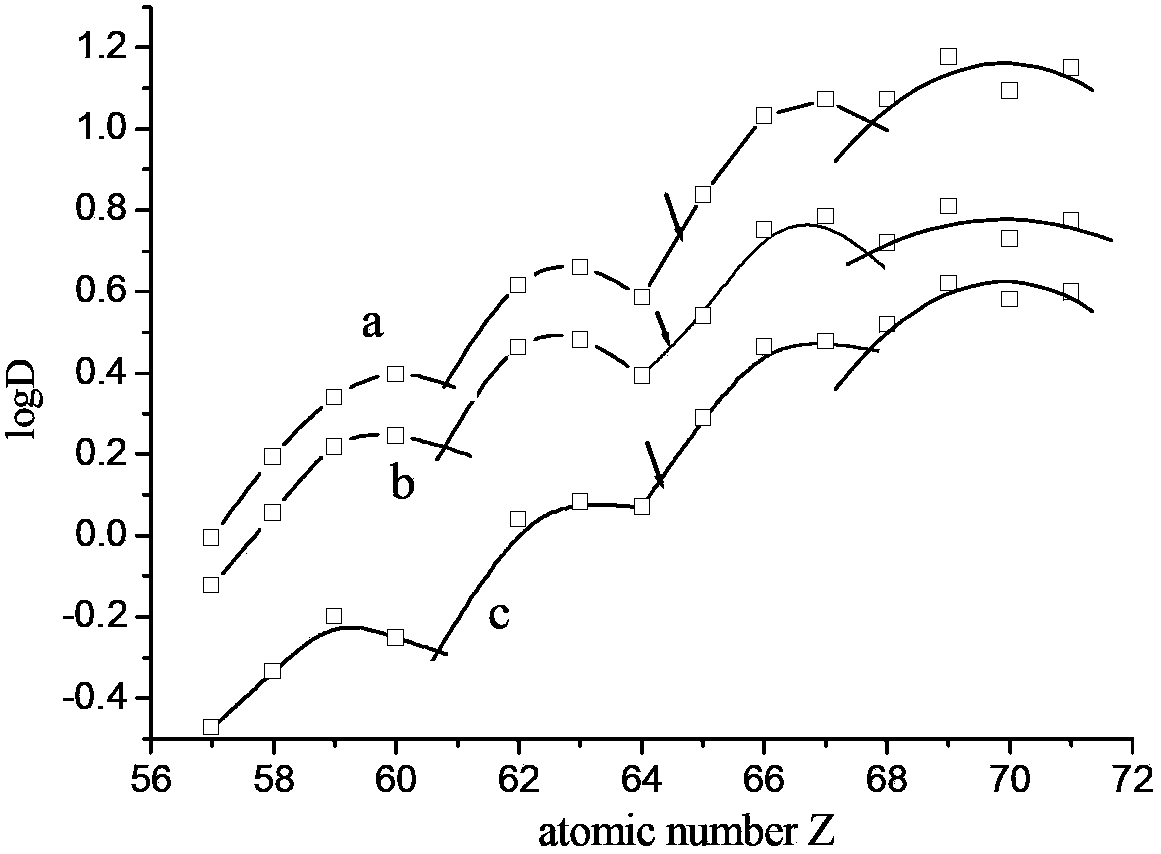

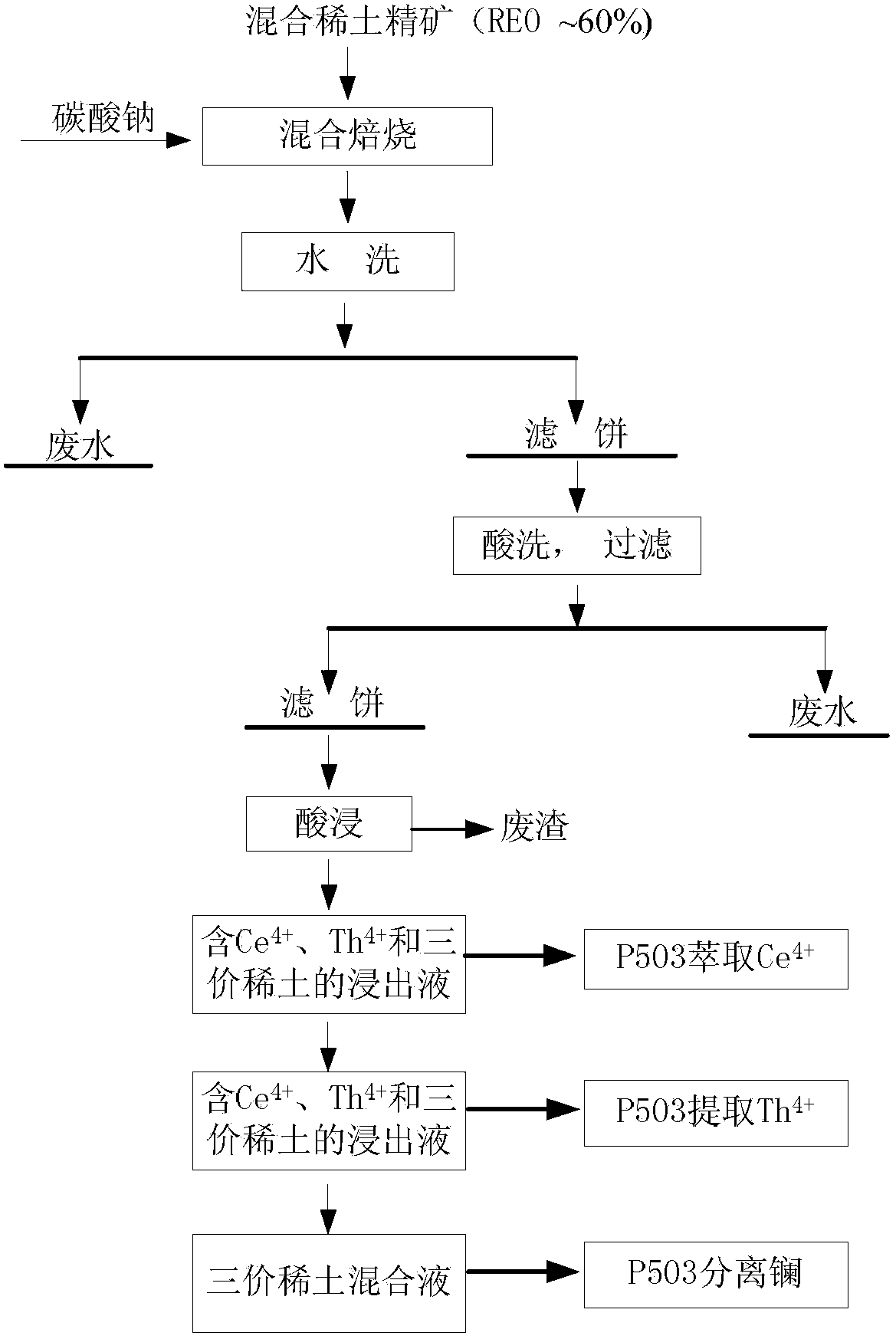

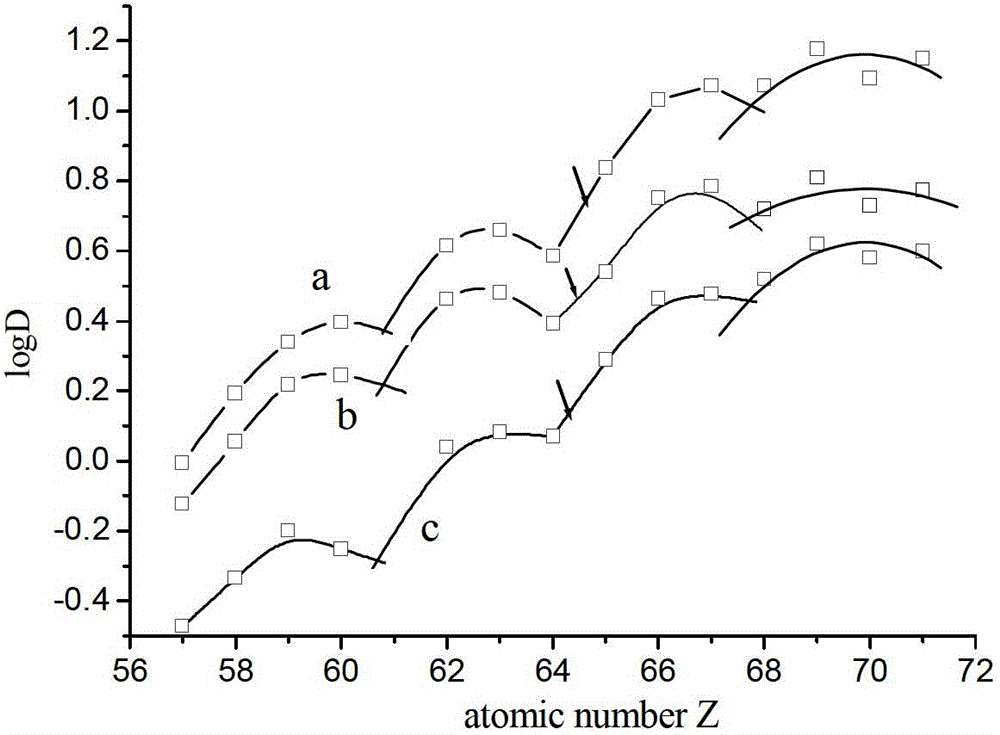

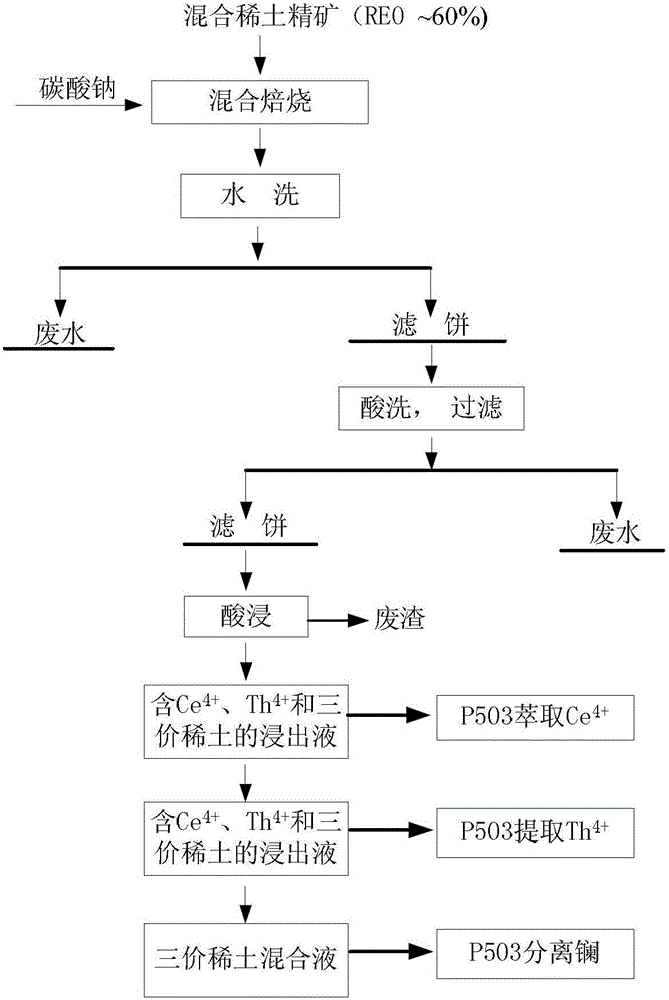

Method of separating lanthanum from rare earth nitrate slurry as well as rare earth ore concentrate separation method

InactiveCN103540746AGood extraction and separation abilityRealize the purpose of separating lanthanumProcess efficiency improvementAlkaneCerium

The invention discloses a method of separating lanthanum from rare earth nitrate slurry as well as a rare earth ore concentrate separation method. The rare earth nitrate slurry does not contain cerium and thorium. The method comprises the following steps: (1) preparing P503 alkane liquor with volume ratio of 30-50% as an extracting agent, and adjusting the pH of the slurry to 2-3; (2) by using sodium nitrate or lithium nitrate liquor as washing liquor, extracting to obtain lanthanum-containing raffinate and a praseodymium- and neodymium-containing organic phase; (3) carrying out countercurrent reverse extraction with sulfuric acid or / and nitric acid as a reverse extraction liquid to obtain a praseodymium and neodymium containing reverse extraction liquid; and (4) adding a rare earth precipitator into the lanthanum-containing raffinate, and roasting the precipitate to obtain lanthanum oxide. Meanwhile, the invention further discloses an extraction and separation method of rare earths in rare earth ore concentrates. One neutral extracting agent is used for extraction and separation of the rare earth ore concentrates, so that the economic pressure of production is relatively low without a transformation step of fully fishing and fully reversing. The neutral extracting agent is used, so that saponification is avoided, and thus the problem that discharge of ammonia-nitrogen wastewater does not reach the standard is eliminated from the source.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of paederia scandens glucoside

InactiveCN102344474ALow costReduce energy consumptionSugar derivativesSugar derivatives preparationChemistryPaederia scandens

The invention relates to a preparation method of paederia scandens glucoside. Paederia scandens is used as a raw material and is crushed, distilled water is added for microwave extraction, and the extract is purified through macroporous resin, then is separated through polyamide columns and is recrystallized to obtain a paederia scandens glucoside product. The method disclosed by the invention has the advantages of large preparation amount and high product purity, the adopted macroporous resin and the polyamide columns can used repeatedly, and the cost is low.

Owner:苏州宝泽堂医药科技有限公司

Calcium removal method for manganese sulfate solution

InactiveCN111392777AHigh purityNo lossManganese compounds preparationManganese sulfatesManganese sulphatePhysical chemistry

The invention provides a calcium removal method for a manganese sulfate solution. The manganese sulfate solution contains impurity calcium ions. The method comprises the following steps: adjusting thepH value of the manganese sulfate solution to 0.5-3; mixing an extraction agent P204 with sulfonated kerosene to obtain an extraction organic phase, the volume concentration of the extraction agent P204 being 5-30%; extracting the manganese sulfate solution by adopting the extraction organic phase to obtain a manganese sulfate calcium-removed raffinate and a calcium-manganese-rich organic phase;carrying out multistage reverse extraction on the calcium-manganese-rich organic phase to obtain a reverse extraction water phase and a reverse extraction organic phase; and carrying out evaporative crystallization on the reverse extraction water phase to obtain a manganese sulfate solid. The process provided by the invention is used for removing calcium from the manganese sulfate solution, givesconsideration to environmental friendliness, low cost and calcium ion removal rate, and has a wide application prospect.

Owner:CHINA ENFI ENGINEERING CORPORATION

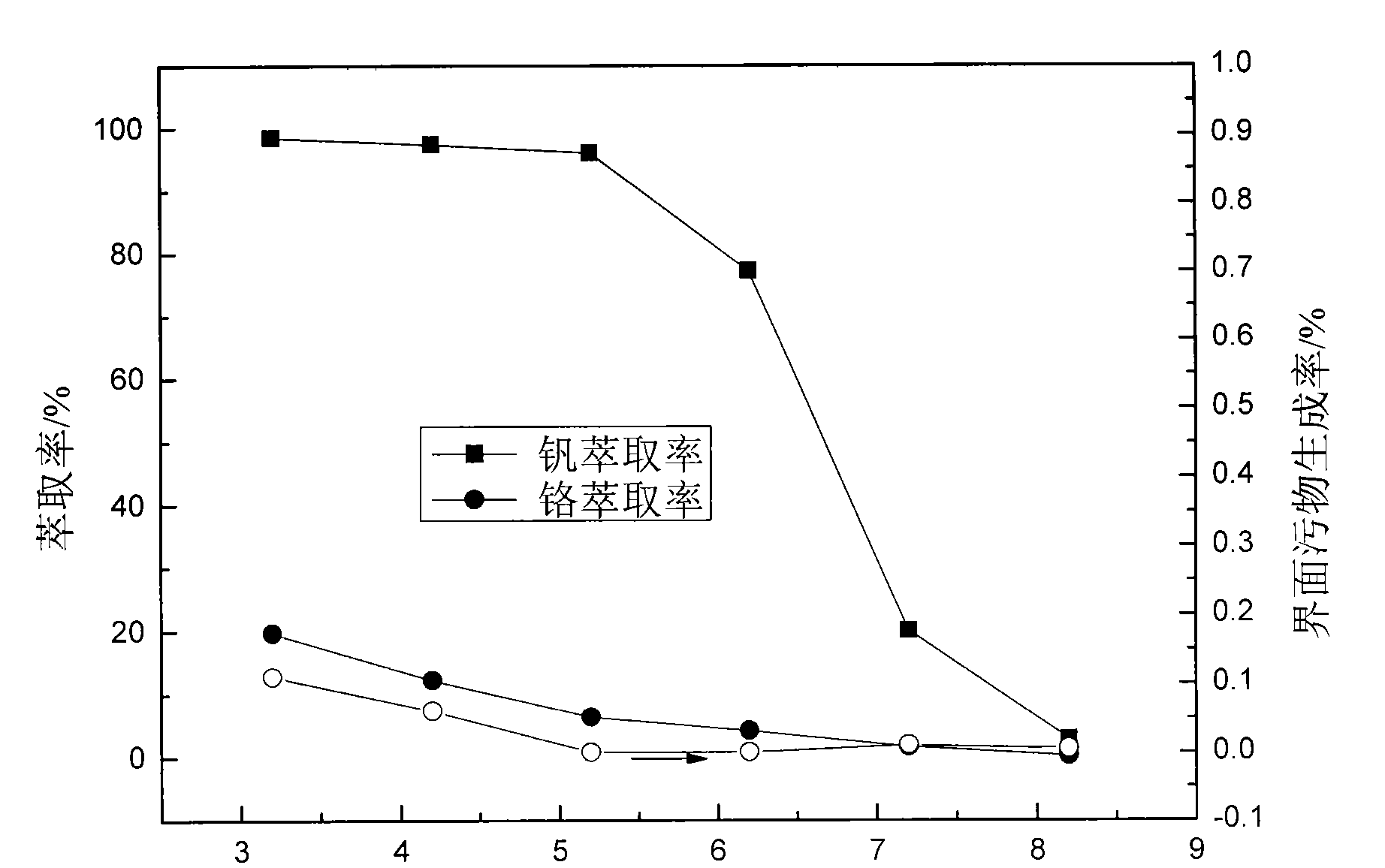

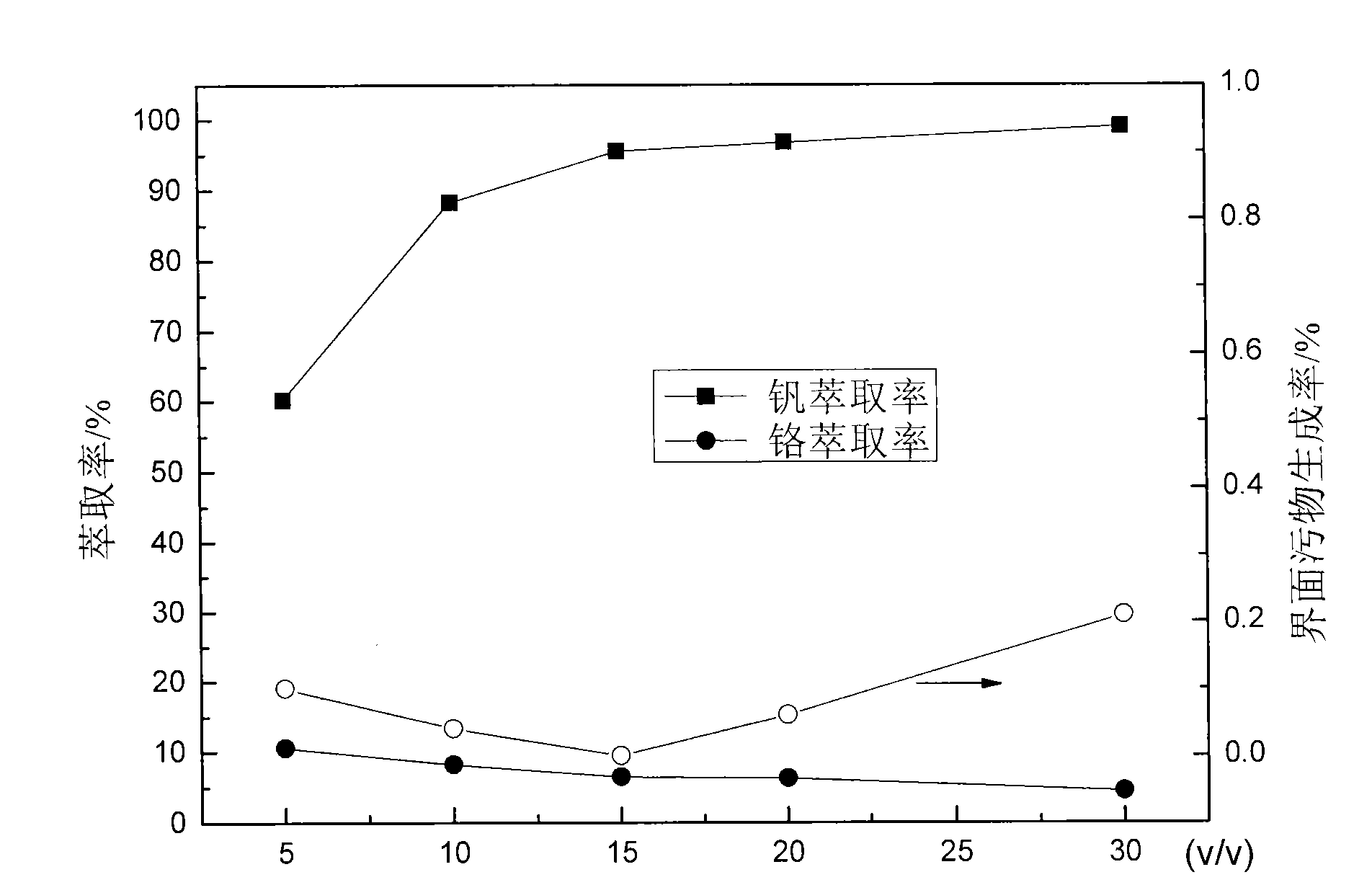

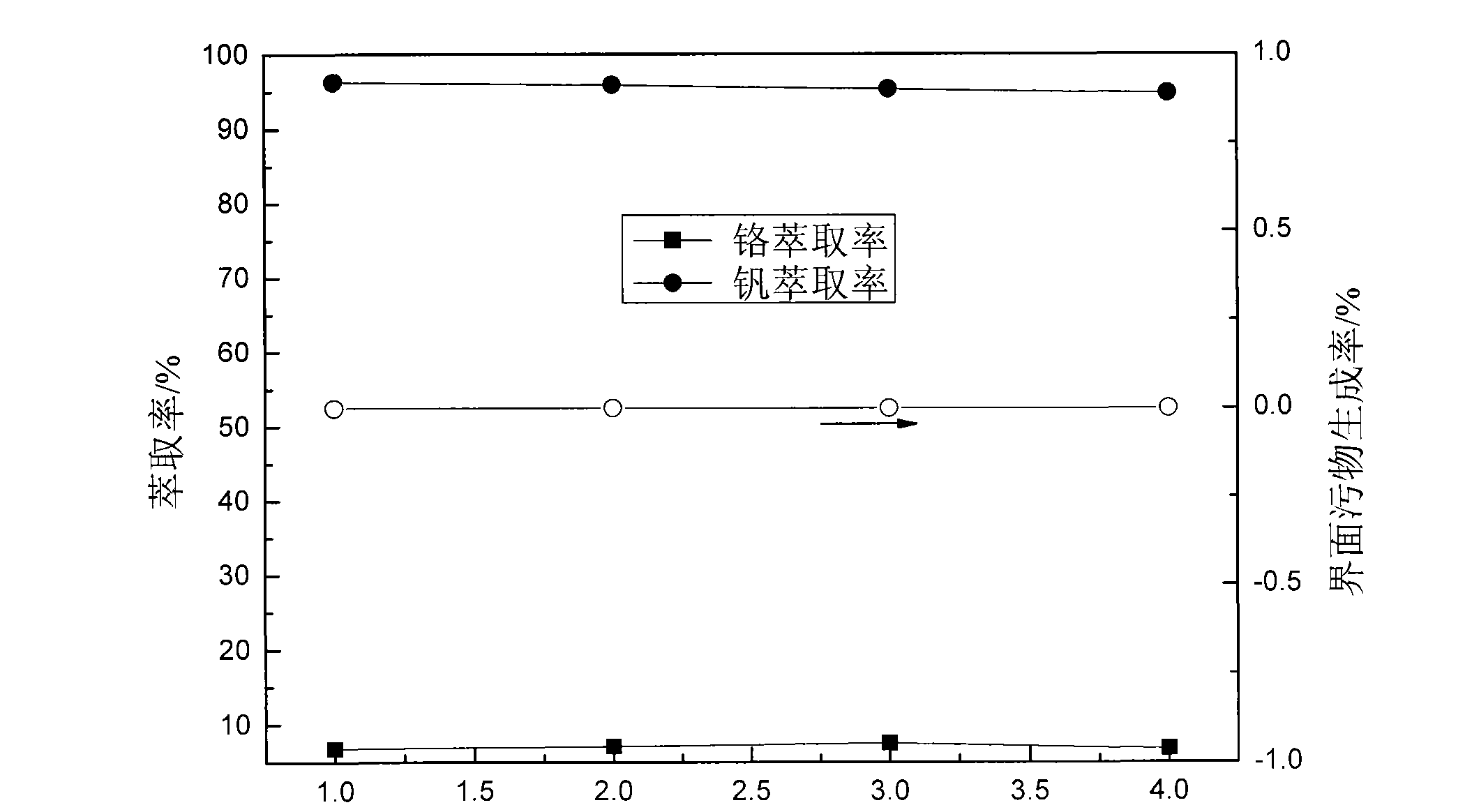

Method for preventing interfacial crud during vanadium-chromium extraction and separation

InactiveCN101665870AInterface contamination preventionEfficient separationProcess efficiency improvementSlagSodium hydroxide

The invention discloses a method for preventing interfacial crud during vanadium-chromium extraction and separation, which is characterized in that during extraction, vanadium and chromium are extracted and separated by use of amine-type extractant in an organic phase containing the amine-type extractant and diluent composition; an aqueous phase adopts a leaching solution which contains vanadium-chromium slag and has acidity adjusted through dilute sulfuric acid or sodium hydroxide solution; and the method comprises the steps of mixing the aqueous phase with the organic phase in a separating funnel at a certain temperature, fixing the separating funnel on an oscillator, oscillating for a certain time, taking out and standing the separating funnel for demixing. The method has the advantagesof effectively preventing interfacial crud produced during vanadium-chromium extraction and separation, improving extraction equilibrium phase-separation speed, reducing the loss of organic phase andsaving operation cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

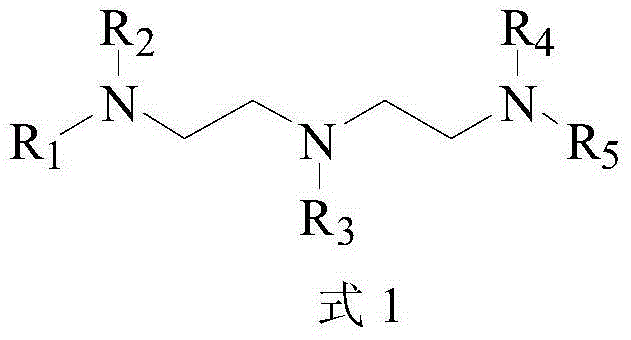

Pentaalkyl-diethylene-tri-tert-amine and its preparation method and use

ActiveCN104311428AEasy to operateMild reaction conditionsProcess efficiency improvementAmino preparation by functional substitutionAlkaneMolybdate

The invention discloses pentaalkyl-diethylene-tri-tert-amine and its preparation method and use. The preparation method comprises that brominated C4-C8 alkane is slowly and dropwisely added into a diethylenetriamine-containing organic solution, the mixed solution is heated and undergoes a replacement reaction in the presence of anhydrous potassium carbonate, and the product is separated and purified to form the pentaalkyl-diethylene-tri-tert-amine having a novel structure. The preparation method has simple processes and mild reaction conditions. The pentaalkyl-diethylene-tri-tert-amine compound can be used as an extraction agent for effective extraction separation of molybdate, tungstateradicle or vanadate anions and widens an extraction agent selection range in the tungsten, molybdenum and vanadium extraction separation technology.

Owner:CENT SOUTH UNIV

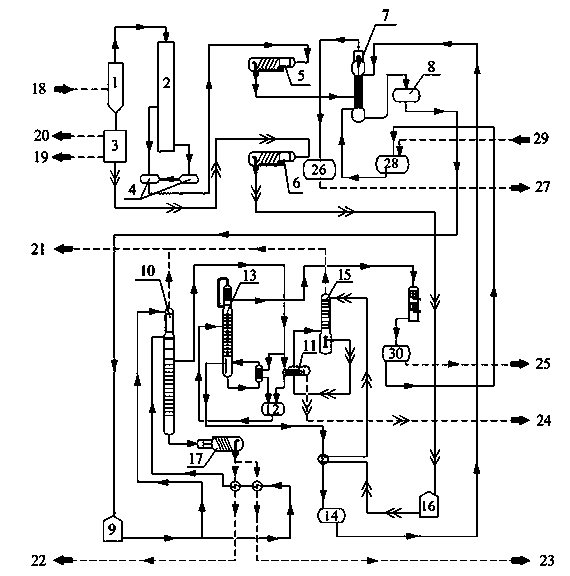

Dephenolization treatment method for coking residual ammonia wastewater

ActiveCN104030486AReduce COD valueAchieve emission reductionOrganic chemistryOrganic compound preparationChemical oxygen demandDistillation

The invention discloses a dephenolization treatment method for coking residual ammonia wastewater. Fixed ammonium surplus ammonia water and free ammonia surplus ammonia water are respectively obtained after a raw coke oven gas is processed, wherein the fixed ammonium surplus ammonia water enters a fixed ammonium dephenolization treatment unit for post-treatment, which comprises three procedures, namely oil-water separation, oil removal in a sedimentation manner, and fixed ammonium decomposition; the free ammonia surplus ammonia water enters a free ammonia dephenolization treatment unit for post-treatment, which comprises five procedures, namely oil removal in a sedimentation manner, extraction and oil removal, steam stripping and dephenolization, distillation and dephenolization, and extraction and dephenolization. By adopting the dephenolization treatment method, the sewage output is effectively reduced, the biochemical treatment pressure is reduced, meanwhile, phenol in the residual ammonia water is effectively recovered, the heat of each procedure is reasonably utilized, the energy cost is effectively reduced, and the chemical oxygen demand (COD) value of the processed wastewater is very low, so as to lay a foundation for simplifying treatment of biochemical wastewater.

Owner:河北协同水处理技术有限公司

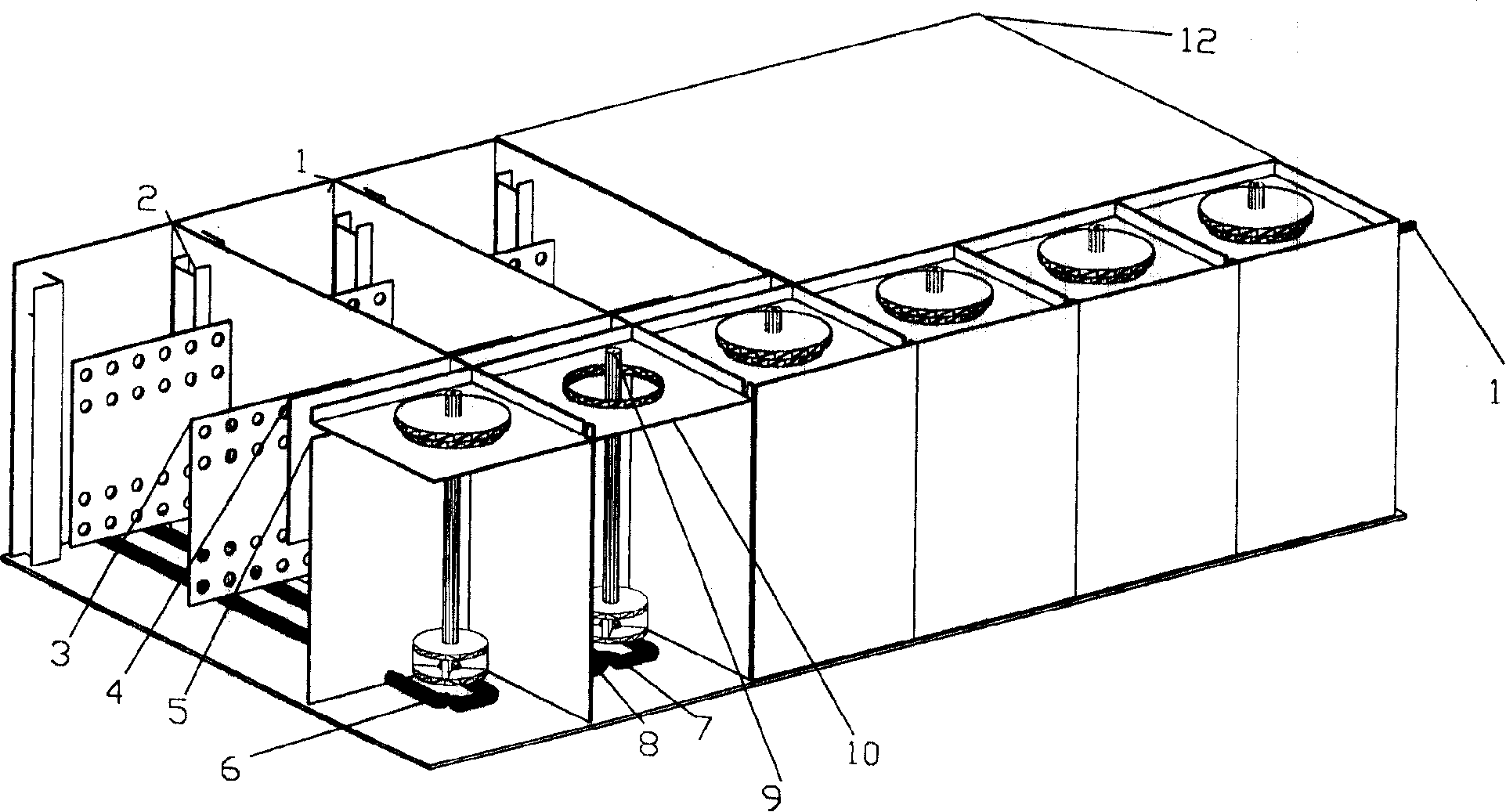

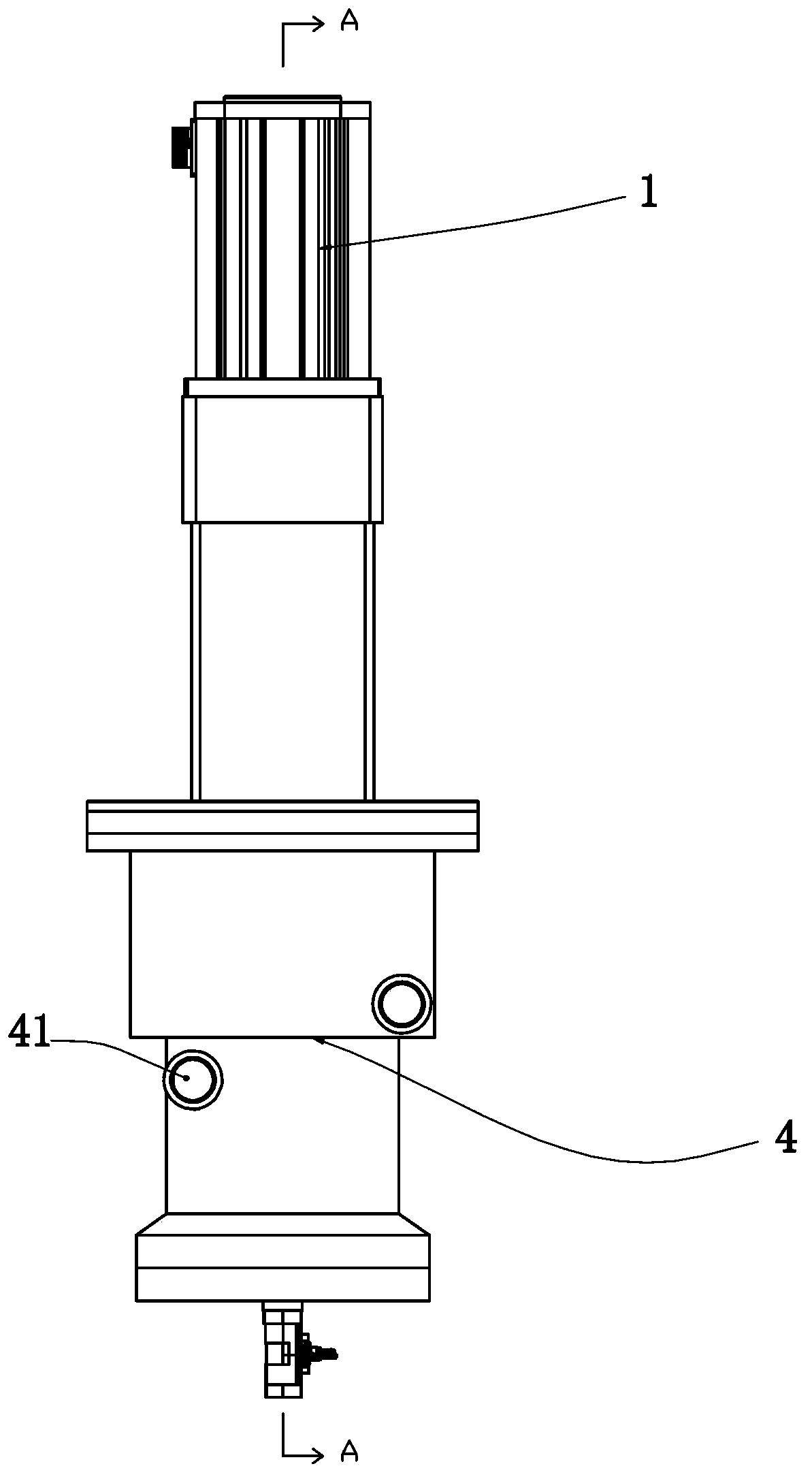

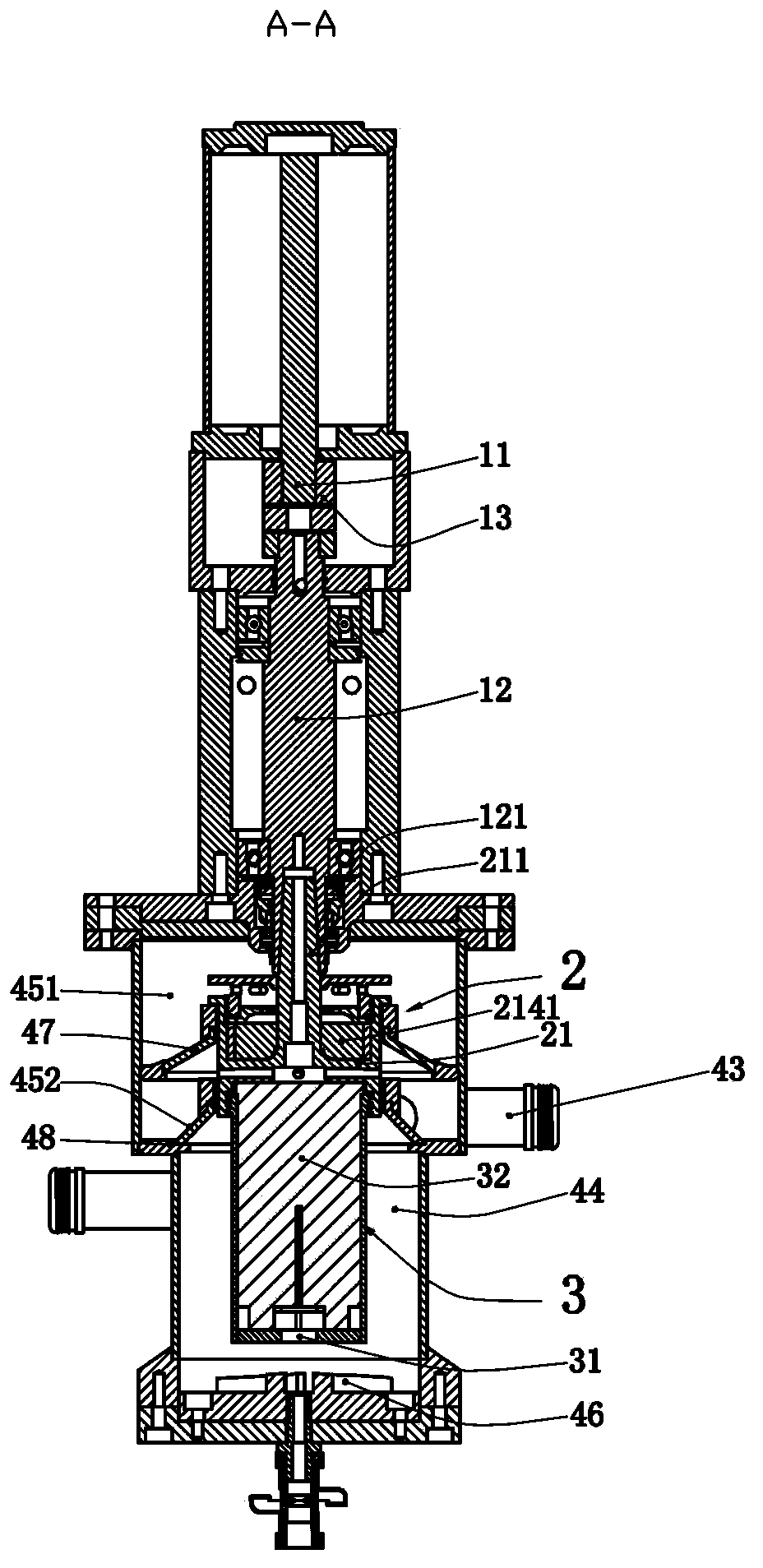

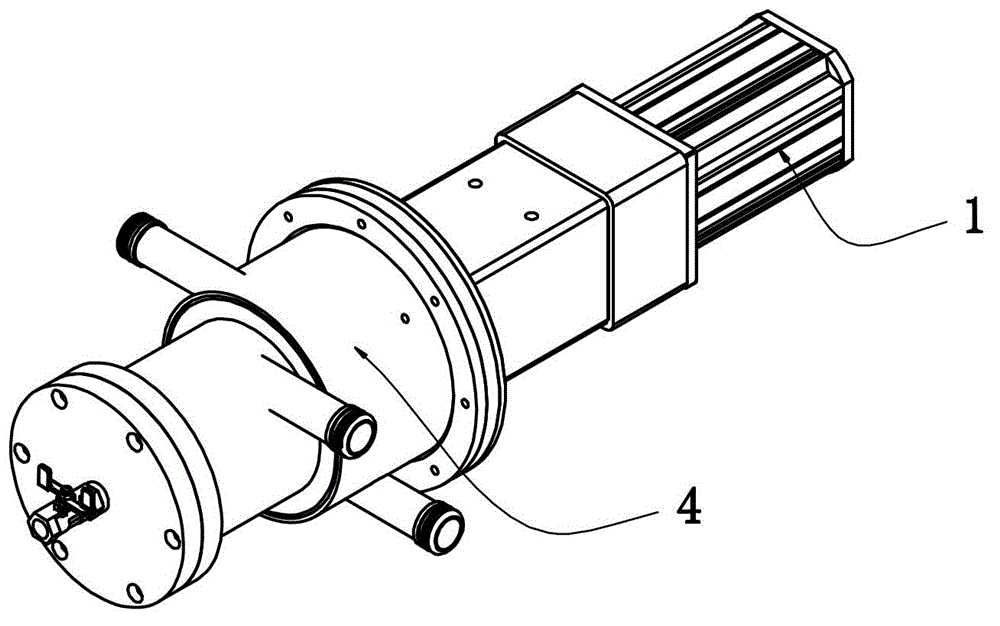

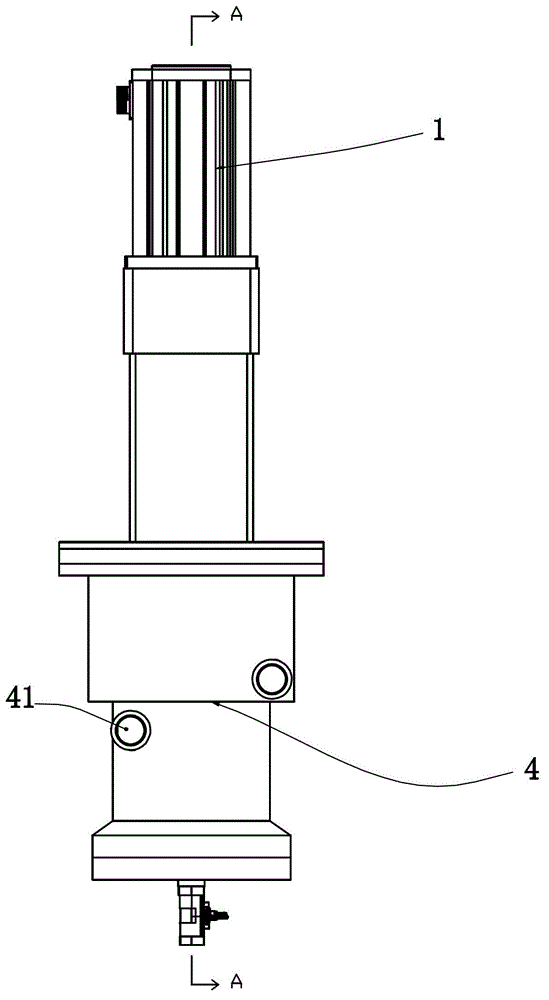

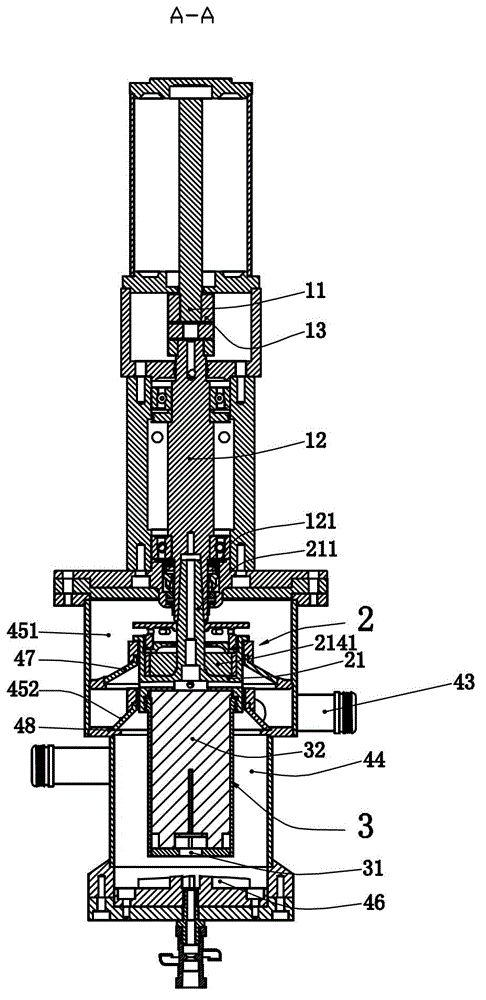

Centrifugal extractor

ActiveCN103349851AReasonable structural designEasy to balanceLiquid solutions solvent extractionEngineeringDynamic balance

The invention discloses a centrifugal extractor which comprises a motor, a flow deflector assembly, a rotary drum and a housing, wherein the flow deflector assembly comprises a flow deflector that is a centrosymmetric structural body, a baffle is arranged in the flow deflector and divides the flow deflector into an inlet chamber and an outlet chamber, a plurality of light-phase flow deflection holes distributed in a central symmetry manner through taking a rotation axis of the flow deflector as the center are formed in the baffle, inlet ends of the light phase flow deflection holes are communicated with the neighborhood of the center of the inlet chamber, outlet ends of the light phase flow deflection holes penetrates from the flow deflector and are communicated with a light phase outlet, a plurality of first heavy phase flow deflection holes communicated with the inlet chamber and the outlet chamber are formed in the baffle, and the first heavy phase flow deflection holes are distributed in a central symmetry manner through taking the rotation axis of the flow deflector as the center. The centrifugal extractor has a reasonable structural design, is convenient to process accurately by means of overall dynamic balance, and is good in dynamic balance; the flow deflector is less in vibration during the high-speed operation process, the two-phase separation interface is stably controlled, the extraction and separation effect is good, and meanwhile, the centrifugal extractor is also applicable to high-speed extraction and separation of materials difficult to separate.

Owner:玄浩

a centrifugal extractor

ActiveCN103349851BGood extraction and separation abilityReduce vibrationLiquid solutions solvent extractionDynamic balanceEngineering

The invention discloses a centrifugal extractor which comprises a motor, a flow deflector assembly, a rotary drum and a housing, wherein the flow deflector assembly comprises a flow deflector that is a centrosymmetric structural body, a baffle is arranged in the flow deflector and divides the flow deflector into an inlet chamber and an outlet chamber, a plurality of light-phase flow deflection holes distributed in a central symmetry manner through taking a rotation axis of the flow deflector as the center are formed in the baffle, inlet ends of the light phase flow deflection holes are communicated with the neighborhood of the center of the inlet chamber, outlet ends of the light phase flow deflection holes penetrates from the flow deflector and are communicated with a light phase outlet, a plurality of first heavy phase flow deflection holes communicated with the inlet chamber and the outlet chamber are formed in the baffle, and the first heavy phase flow deflection holes are distributed in a central symmetry manner through taking the rotation axis of the flow deflector as the center. The centrifugal extractor has a reasonable structural design, is convenient to process accurately by means of overall dynamic balance, and is good in dynamic balance; the flow deflector is less in vibration during the high-speed operation process, the two-phase separation interface is stably controlled, the extraction and separation effect is good, and meanwhile, the centrifugal extractor is also applicable to high-speed extraction and separation of materials difficult to separate.

Owner:玄浩

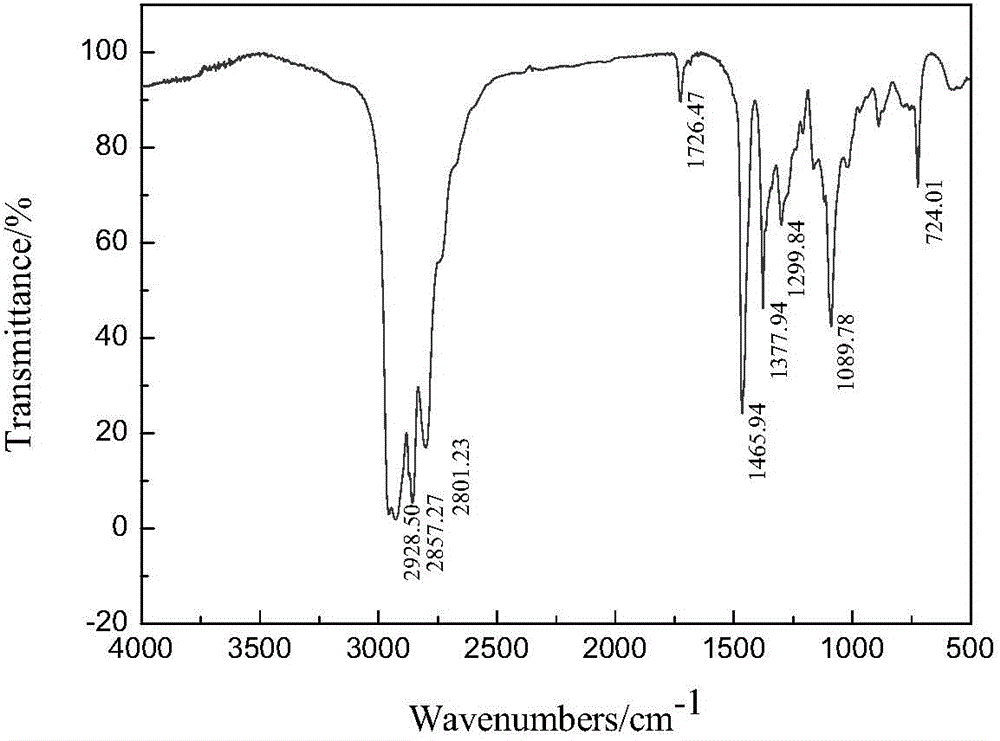

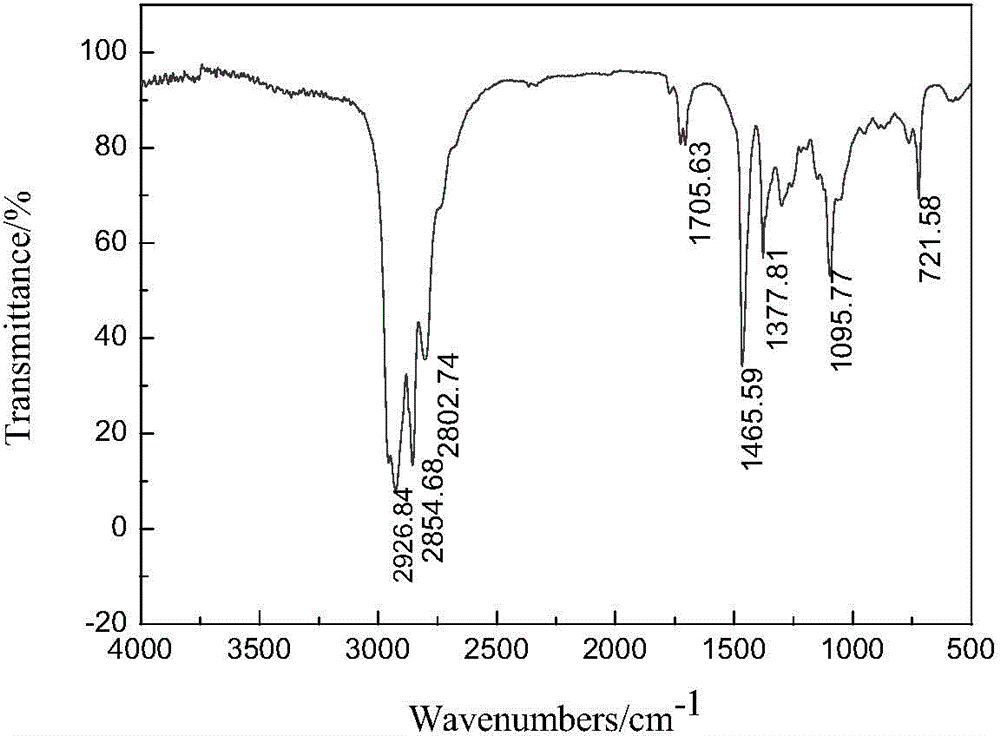

Preparation method of dialkylphosphinic acid extracting agent

InactiveCN104151353AGood extraction and separation abilityResponse requirements are lowGroup 5/15 element organic compoundsRadical substitutionSodium Hypophosphite Monohydrate

The invention provides a preparation method of a dialkylphosphinic acid extracting agent. The preparation method comprises the following steps: mixing octene, decene and dodecene at a certain ratio; after catalytically reforming the mixture, catalyzing the mixture in an acidic medium by using oxide; enabling the mixture and sodium hypophosphite to be subjected to free radial substitution reaction at normal pressure to obtain a dialkylphosphinic acid mixture at high yield. The dialkylphosphinic acid mixture has extremely good extraction and separation effects for nickel and cobalt and is especially suitable for a high-nickel and low-cobalt system.

Owner:TIANJIN JUDE TECH

Preparation method of medicine preparation for treating common cold in children

InactiveCN105456834AAvoid degradationPrevent volatilizationPill deliveryGranular deliveryCommon coldSeparation technology

The invention relates to a preparation method of a medicine preparation for treating the common cold in children. The granule for treating the common cold in children is prepared from fifteen herbal medicine materials including honeysuckle, phillyrin, fructus arctii, mint, schizonepetaspike, radix scutellariae, cape jasmine (fried), semen armeniacae amarum, radix platycodi, radix peucedani, radix angelicae dahuricae, hawthorn (burnt), medicated leaven (burnt), malt (burnt), rhizoma phragmitis and the like. The preparation is formed through cyclodextrin wrapping, granulating, granule finishing and subpackaging by means of the modern extraction separation technology of supercritical fluid extraction, ultrasonic extraction, micro-aperture filter membrane filtering and the like. The method is good in extraction separation effect, high in extraction efficiency, and capable of saving energy and cost; the wrapper preparation technology is adopted for the product, the volatilization of volatile oil type functional components is avoided, the bad smell of the product is covered, and the product quality and child patient medicine taking compliance are further improved.

Owner:JIANGXI KINGSTONE UNITE PHARMA CO LTD

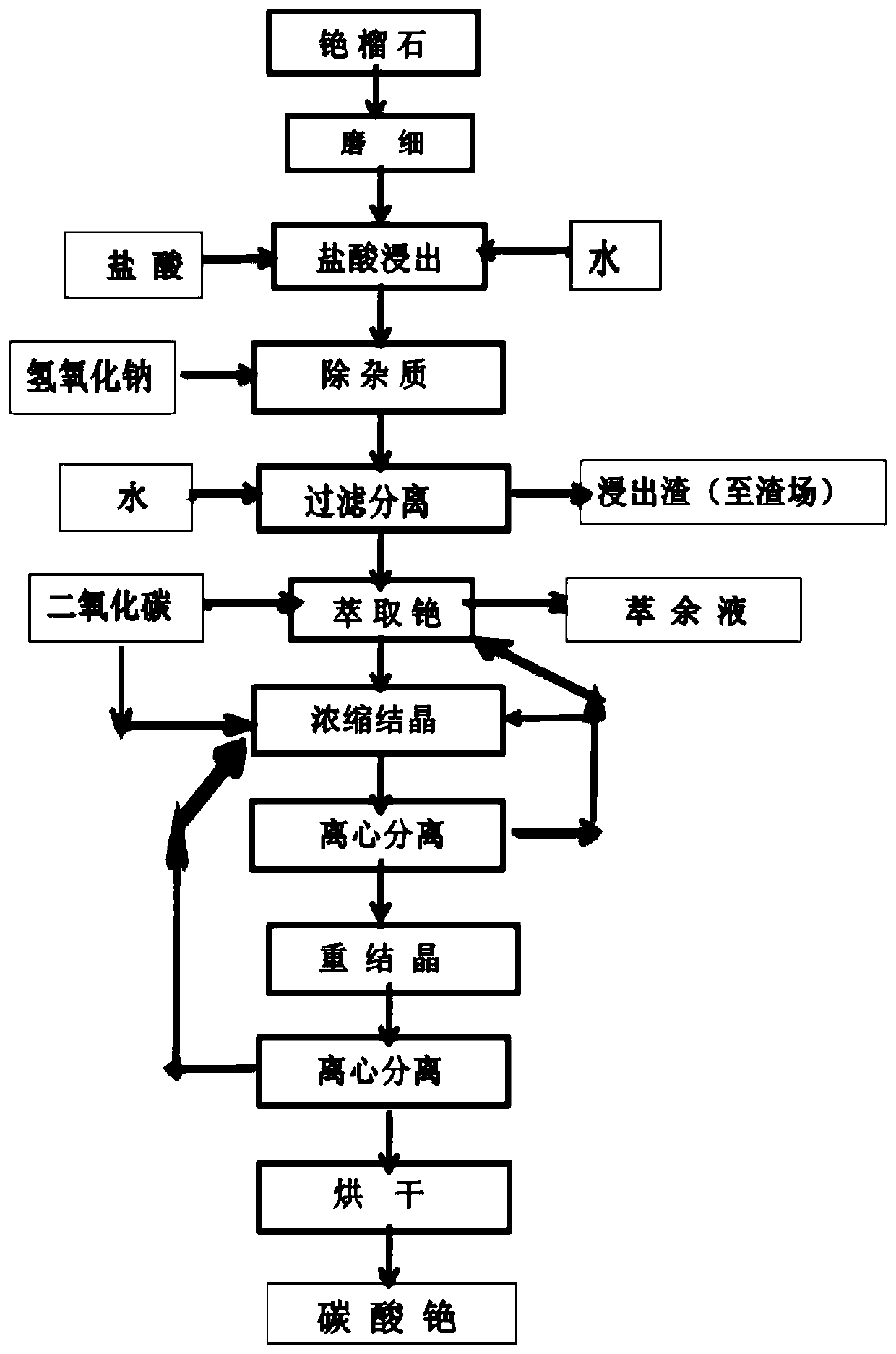

Method for extracting high-purity cesium carbonate from pollucite

InactiveCN110078100AHigh recovery rateImprove leaching effectRubidium/caesium/francium compoundsPolluciteCarbonization

The invention discloses a method for extracting high-purity cesium carbonate from pollucite. The method comprises steps as follows: 1, leaching of pollucite with hydrochloric acid; 2, impurity removalwith a precipitation method; 3, extraction and separation of caesium with a special extracting agent; 4, reextraction with carbon dioxide; 5, deep carbonization through charging of carbon dioxide during concentration of a reextraction solution; 6, recrystallization and purification of a crude product. Cerium in pollucite ore is leached with a hydrochloric acid method, a high-purity single ceriumproduct is obtained with an extraction method, the cerium leaching effect is good, the yield is high, and the extraction and separation effect is good. Carbon dioxide is used for reextraction, and carbon dioxide is charged for deep carbonization during concentration, so that the finally obtained cesium carbonate has the purity of 99.99% or above, cesium carbonate is easily converted into chlorate,sulfate, nitrate, formate and other products. The technological process is simple, few solid wastes are produced, no harmful metal elements are introduced, and thus, the method is safer and more environmentally friendly.

Owner:JIANGXI DONGPENG NEW MATERIALS

Use and method of amino acid-containing phosphine extractant for extracting and separating cobalt and nickel

ActiveCN109097570BAchieve separationHigh industrial application valueProcess efficiency improvementPhysical chemistryOrganic chemistry

The present invention relates to the use and method of the amino acid-containing phosphine extractant of the following general formula I for the extraction and separation of cobalt and nickel, wherein R 1 from C 1 ~C 12 Alkyl, R 2 from C 1 ~C 14 alkyl. The method comprises the step of using the amino acid-containing phosphine extractant of the general formula I to extract and separate nickel from a feed solution containing cobalt and nickel. The method of the present invention can preferentially extract nickel, so as to realize the separation of nickel and cobalt, so it has significant advantages in separating low-nickel and high-cobalt feed liquid. In addition, the amino acid-containing phosphine extractant used in the present invention can not only separate cobalt and nickel in different acid media, but also has good extraction and separation capabilities, and the synthesis method is simple, the cost is low, the property is stable, and it is easy to realize industrialization. It has high industrial application value.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Fresh zanthoxylum oil resin separation and purification process

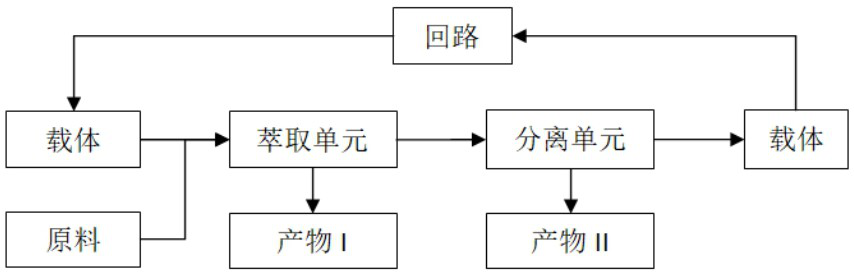

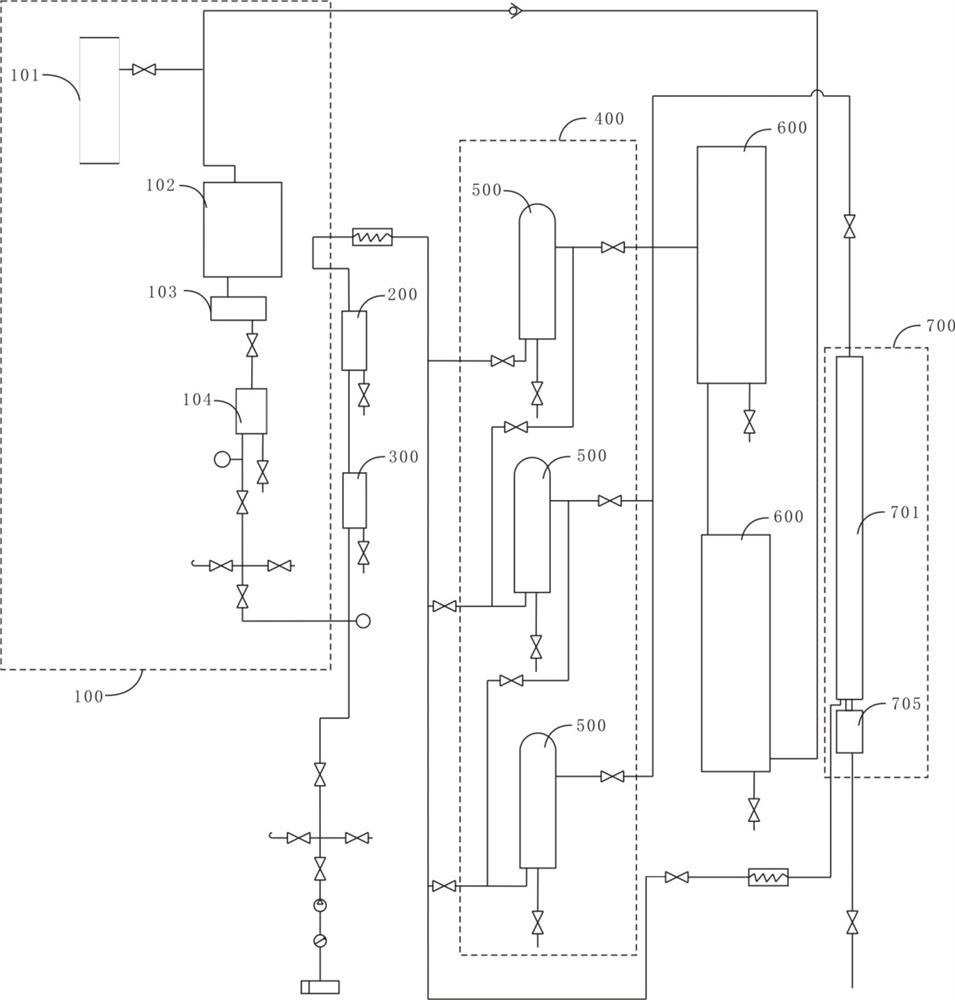

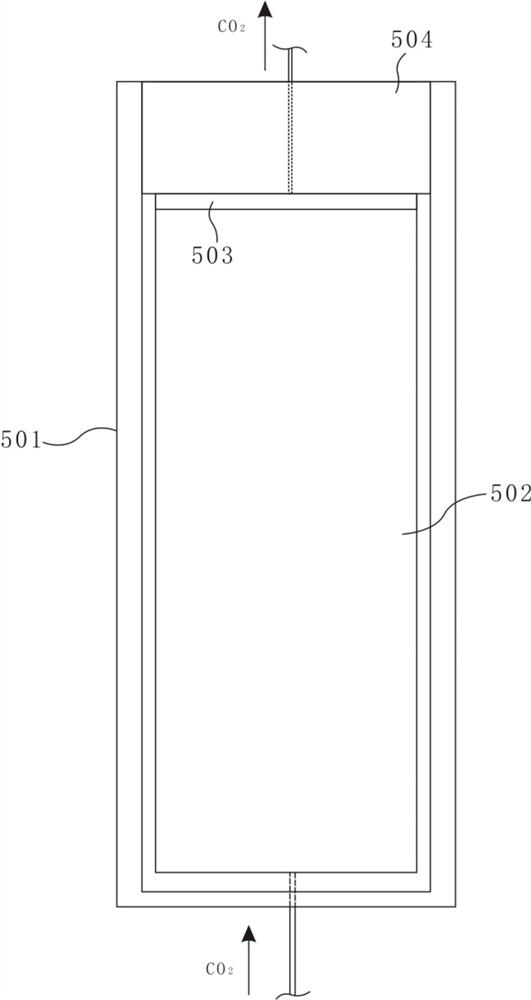

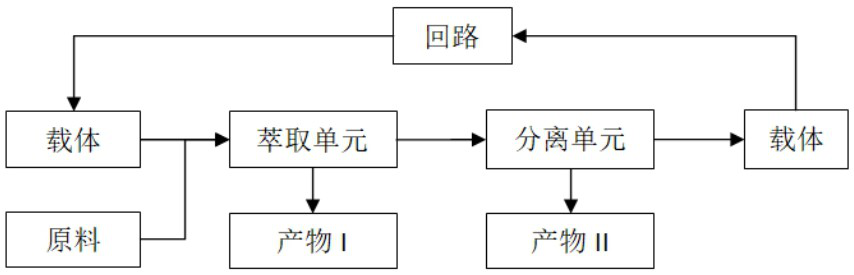

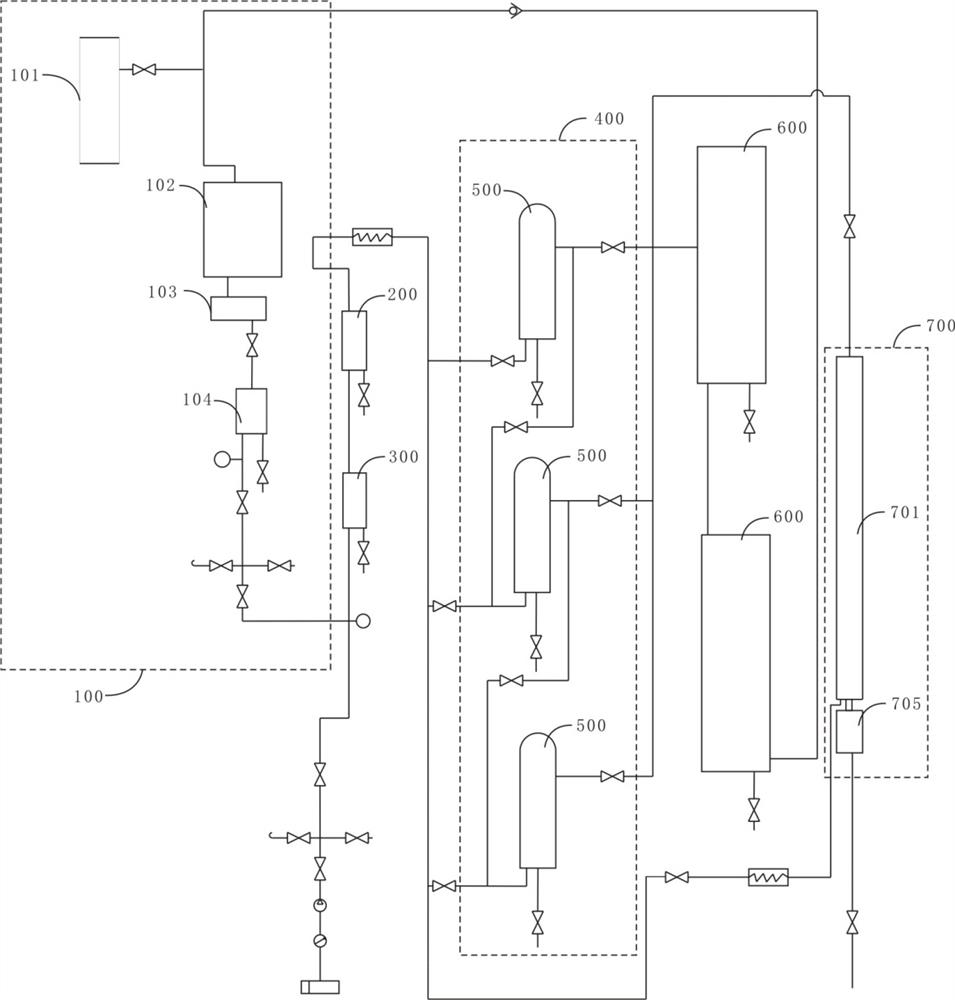

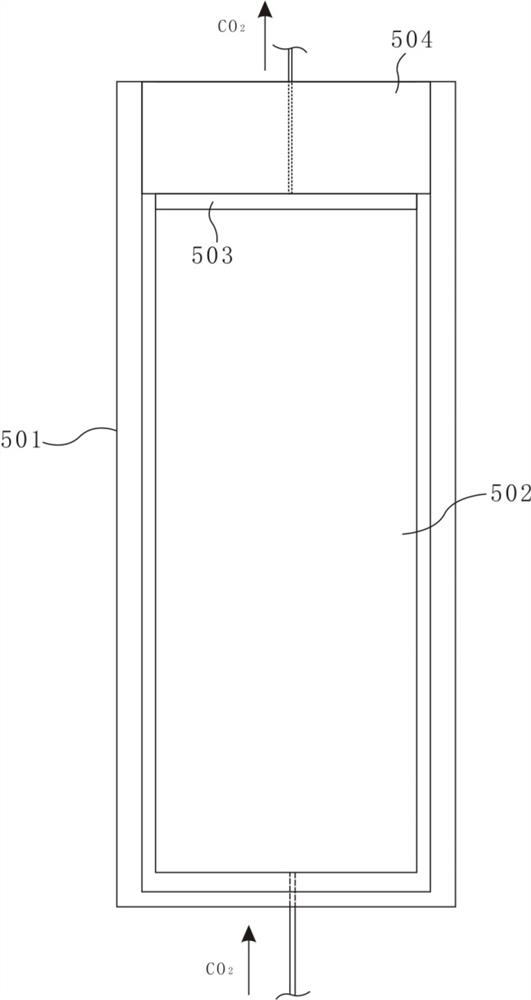

InactiveCN113430053AExtraction achievedAchieve independenceCounter-current extractionEssential-oils/perfumesZanthoxylum bungeanumPhysical chemistry

The invention discloses a fresh zanthoxylum oleoresin separation and purification process which comprises the following steps: after harvesting fresh zanthoxylum, carrying out cold pressing within two hours to obtain fresh zanthoxylum oleoresin, carrying out countercurrent extraction separation on the fresh zanthoxylum oleoresin through a liquid substance extraction and separation unit of a supercritical CO2 fluid dynamic countercurrent extraction and separation system, and after the countercurrent extraction separation is completed, obtaining fresh zanthoxylum resin from an extraction unit, and obtaining the fresh pepper essential oil through the separation unit. The extraction separation process is as follows: the feeding rate is 40kg / h, the CO2 flow rate is 600L / h, the extraction temperature is 45 DEG C, and the extraction pressure is 20MPa; the separation temperature I is 40 DEG C, the separation pressure I is 7.5 MPa, the separation temperature is 55 DEG C, and the separation pressure II is 4-6 MPa; the total yield of the fresh zanthoxylum oil resin product reaches 98.74%-99.19%, and the separation efficiency reaches 94.00%-99.24%; the volatile oil content of the obtained fresh zanthoxylum bungeanum essential oil can reach 101.94-128.93 ml / 100g, and the numb degree is lower than 5 mg / g; and the content of volatile oil in the obtained fresh zanthoxylum bungeanum maxim resin is smaller than 5 ml / 100 g, the hemp degree can reach 141.12 mg / g to 182.56 mg / g, and the hemp degree is increased to 42.59% to 53.17%. According to the process disclosed by the invention, the fresh Chinese prickly ash essential oil with high volatile oil content and the fresh Chinese prickly ash resin with high numb degree can be obtained, and the purification effect of the two products is remarkable.

Owner:四川丁点儿食品开发股份有限公司

Fresh pericarpium zanthoxyli oleoresin separation and purification process

PendingCN113563975AExtraction achievedAchieve independenceCounter-current extractionEssential-oils/perfumesPhysical chemistryOleoresin

The invention discloses a fresh pericarpium zanthoxyli oleoresin separation and purification process which comprises the following steps: after harvesting fresh pericarpium zanthoxyli, carrying out cold pressing within two hours to obtain fresh pericarpium zanthoxyli oleoresin, carrying out countercurrent extraction separation on the fresh pericarpium zanthoxyli oleoresin through a liquid substance extraction and separation unit of a supercritical CO2 fluid dynamic countercurrent extraction and separation system, and after the countercurrent extraction separation is completed, obtaining fresh pericarpium zanthoxyli resin from the extraction unit, and obtaining fresh pericarpium zanthoxyli essential oil through a separation unit. The extraction separation process is as follows: the feeding rate is 40kg / h, the CO2 flow rate is 600L / h, the extraction temperature is 45 DEG C, and the extraction pressure is 20MPa; the separation I temperature is 40 DEG C, the separation I pressure is 7.5 MPa, the separation II temperature is 55 DEG C, and the separation II pressure is 4-6 MPa; the total yield of the oleoresin product reaches 98.74%-99.17%, and the separation efficiency of volatile oil reaches 94.00%-99.24%; the volatile oil content of the obtained essential oil can reach 101.94-128.93 ml / 100g; the content of amide substances in the obtained resin can reach 575.22 mg / g to 645.99 mg / g, and the content of the amide substances is increased to 79.08% to 98.25%. According to the process disclosed by the invention, the fresh pericarpium zanthoxyli essential oil with high volatile oil content and the fresh pericarpium zanthoxyli resin with a high amide substance content can be obtained, and the purification effect of the two products is remarkable.

Owner:四川丁点儿食品开发股份有限公司

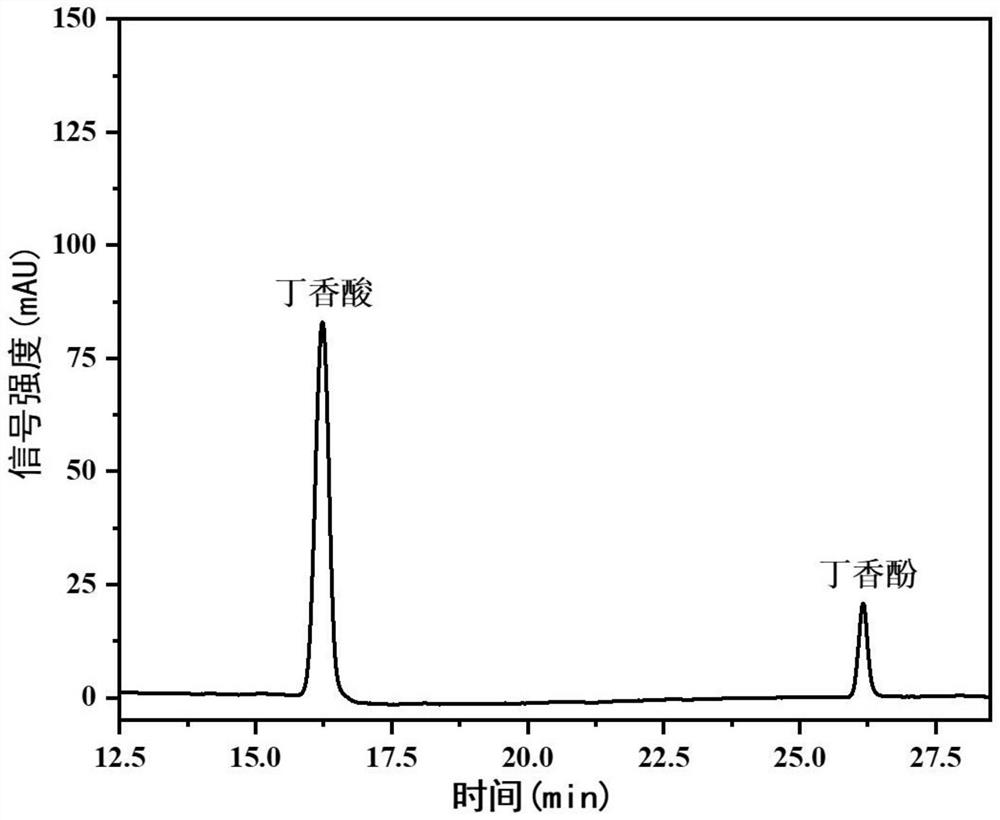

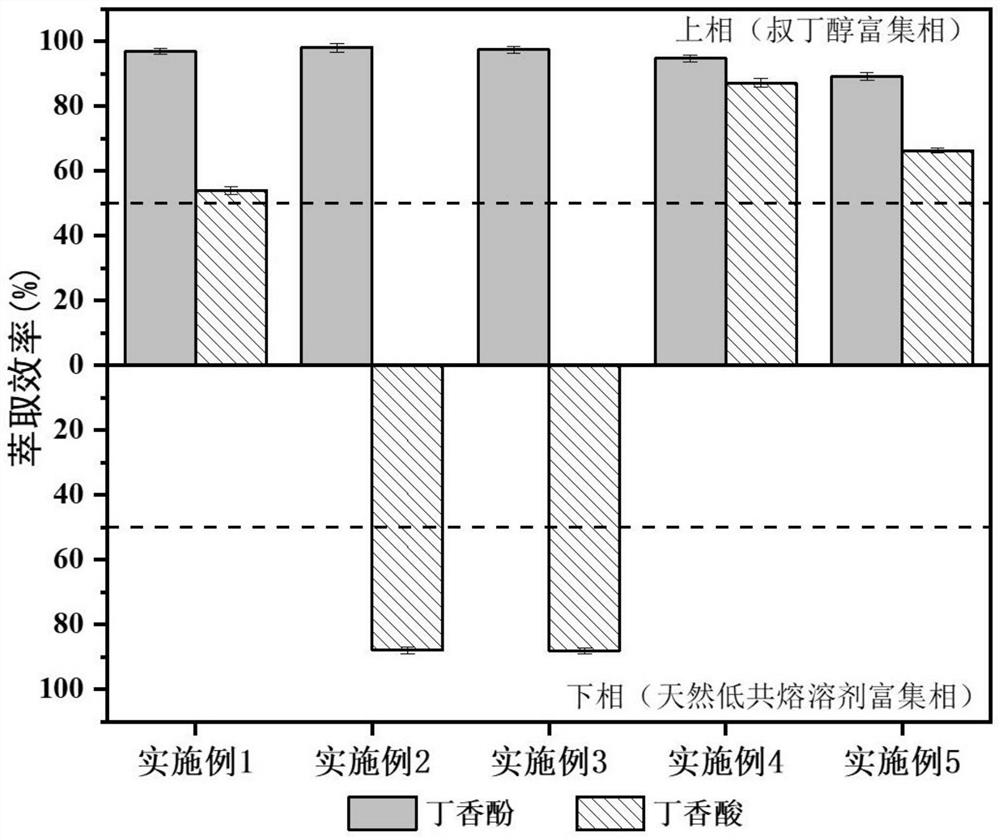

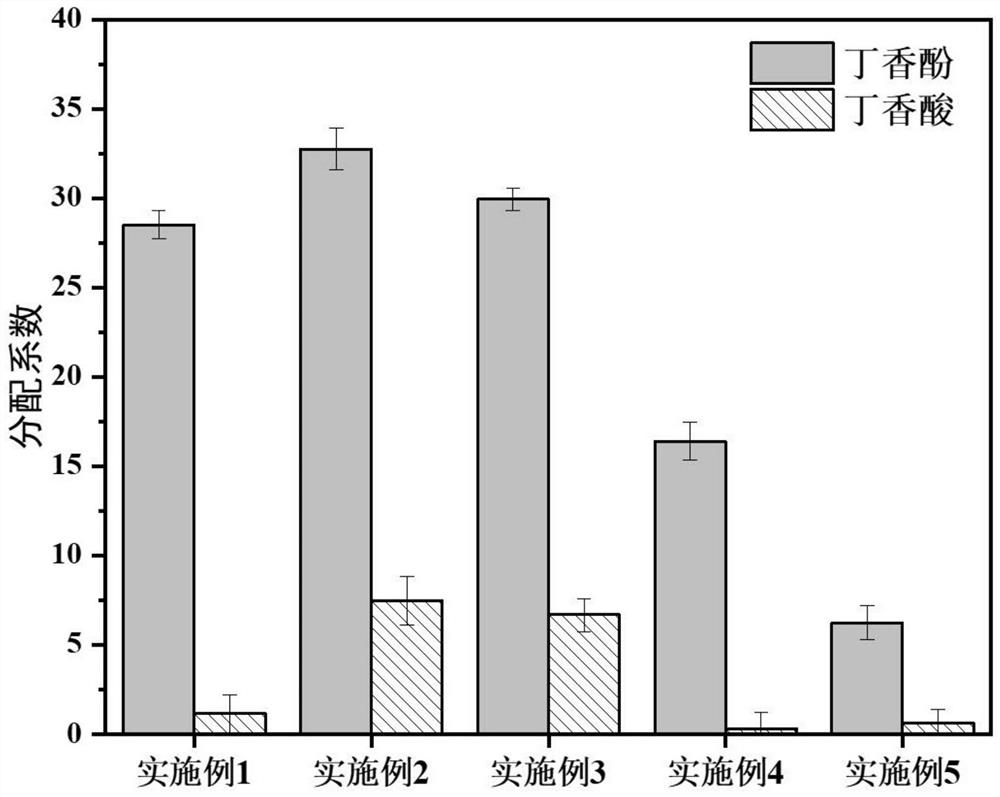

Method for extracting and separating eugenol and syringic acid by using aqueous two-phase system

ActiveCN113372202AEasy to operateLow costEther separation/purificationOrganic compound preparationEugenolSolvent

The invention discloses a method for extracting and separating eugenol and syringic acid by using an aqueous two-phase system, which comprises the following steps: adding an aqueous solution containing eugenol and syringic acid into an extracting solvent consisting of a natural eutectic solvent and tert-butyl alcohol, and carrying out aqueous two-phase extraction to respectively obtain eugenol and syringic acid. The method disclosed by the invention is simple to operate, low in cost, green and efficient, eugenol and syringic acid can be enriched and recovered from the aqueous solution, and the problems of complicated operation, high cost, high equipment requirement, difficulty in recovery of bioactive substances and high toxicity and high volatility of an extraction solvent in a traditional extraction and separation method are solved.

Owner:SOUTH CHINA UNIV OF TECH

Method of separating lanthanum from rare earth nitrate slurry as well as rare earth ore concentrate separation method

InactiveCN103540746BGood extraction and separation abilityRealize the purpose of separating lanthanumProcess efficiency improvementAlkaneCerium

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Cylindrical Centrifugal Extractor

ActiveCN103830933BLarge adjustment rangeSmall sizeLiquid solutions solvent extractionImpellerEngineering

Owner:广州富一液体分离技术有限公司

A kind of dephenol treatment method of coking residual ammonia water

ActiveCN104030486BReduce COD valueAchieve emission reductionOrganic chemistryOrganic compound preparationChemical oxygen demandDistillation

The invention discloses a dephenolization treatment method for coking residual ammonia wastewater. Fixed ammonium surplus ammonia water and free ammonia surplus ammonia water are respectively obtained after a raw coke oven gas is processed, wherein the fixed ammonium surplus ammonia water enters a fixed ammonium dephenolization treatment unit for post-treatment, which comprises three procedures, namely oil-water separation, oil removal in a sedimentation manner, and fixed ammonium decomposition; the free ammonia surplus ammonia water enters a free ammonia dephenolization treatment unit for post-treatment, which comprises five procedures, namely oil removal in a sedimentation manner, extraction and oil removal, steam stripping and dephenolization, distillation and dephenolization, and extraction and dephenolization. By adopting the dephenolization treatment method, the sewage output is effectively reduced, the biochemical treatment pressure is reduced, meanwhile, phenol in the residual ammonia water is effectively recovered, the heat of each procedure is reasonably utilized, the energy cost is effectively reduced, and the chemical oxygen demand (COD) value of the processed wastewater is very low, so as to lay a foundation for simplifying treatment of biochemical wastewater.

Owner:河北协同水处理技术有限公司

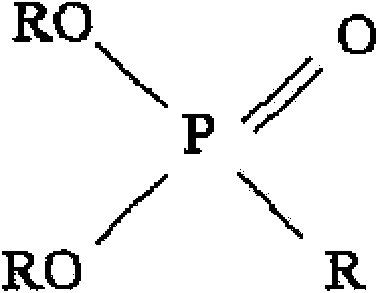

Use and method of amino-containing neutral phosphine extractant for extracting and separating tetravalent cerium

ActiveCN105734288BGood extraction and separation abilityThe synthesis method is simpleProcess efficiency improvementHydrogenCerium

A use of an amino group-containing neutral phosphine extraction agent having the following formula I for the extraction and separation of tetravalent cerium, and a method using the amino group-containing neutral phosphine extraction agent having formula I to extract and separate tetravalent cerium. R1 and R2 are each independently selected from C1-C12 alkyl groups, R3 and R4 are each independently selected from C1-16 alkyl groups and hydrogen, and n is an integer from 1 to 8.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Use and method of neutral phosphine extractant for extracting and separating cerium (iv) or thorium (iv)

ActiveCN107287419BGood extraction and separation abilityThe synthesis method is simpleProcess efficiency improvementHydrogenCerium

The present invention relates to the use and method of an amino-containing neutral phosphine extractant of the following general formula I for extracting and separating Ce(IV) or Th(IV): wherein, R1 and R2 are each independently selected from C1~C12 alkyl groups; R3 and R4 are each independently selected from C1-C5 alkyl and hydrogen, and at most one of R3 and R4 is hydrogen; R5 and R6 are each independently selected from C1-C16 alkyl and hydrogen, and at most one of R5 and R6 is hydrogen.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Use and method of amino-containing neutral phosphine extractant for extracting and separating uranium

ActiveCN106521153BGood extraction and separation abilityReduce the cost of extraction and separationHydrogenSynthesis methods

The present invention relates to the use and method of an amino-containing neutral phosphine extractant of the following general formula I for extracting and separating uranium, wherein R1 and R2 are each independently selected from C1-12 alkyl groups; R3 and R4 are each independently selected from C1 -5 alkyl and hydrogen, R5 and R6 are each independently selected from C1-16 alkyl and hydrogen, and at most one of R5 and R6 is hydrogen. The amino-containing neutral phosphine extractant used in the present invention not only has a good extraction and separation ability for uranium in different acid media, but also has a simple synthesis method, and the chemical raw materials used in the synthesis are simple and easy to obtain, and the cost is low, so that the uranium can be effectively reduced. The cost of extraction and separation has high industrial application value. According to the method of the present invention, liquid-liquid extraction separation or solid-liquid extraction is used to separate uranium in uranium-containing raw materials. The results show that the purity of uranium obtained after extraction, washing and stripping is more than 99%, and the yield of uranium is More than 98%, effectively realizing the enrichment and purification of uranium.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

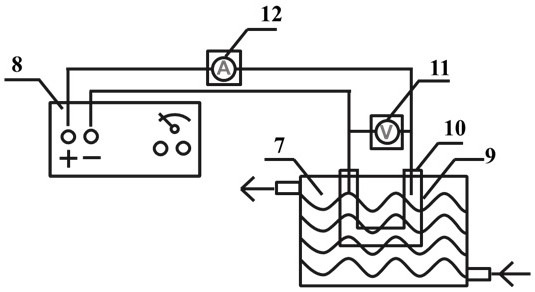

Method for improving divalent metal extraction separation difference

ActiveCN113549760AImprove Extraction Separation VariationImprove separation and extraction efficiencyProcess efficiency improvementHydration reactionDivalent metal ions

The invention discloses a method for improving divalent metal extraction separation difference, and belongs to the technical field of extraction separation. The method comprises the following step that in a liquid-liquid extraction process, energy is supplied to a mixed solution containing two divalent metal ions and an organic phase in a manner of applying an external field; the external field is an ultrasonic external field or an electrostatic field, and the separation effect of any two kinds of metals is enhanced by adjusting ultrasonic power or electric field voltage; and the hydration degree difference of the two divalent metals is maximized in a specific energy range, and the extraction separation difference of the divalent metals is improved. According to the method, the extraction separation difference of the two divalent metals can be remarkably improved, the extraction separation efficiency of the two divalent metals is improved, and the extraction separation effect of the two divalent metals is improved. The method belongs to a novel non-saponification extraction technology, and is beneficial to solving the problem of environmental pollution in the heavy metal extraction and saponification link from the source. Compared with a traditional non-saponification treatment method, the method has the advantages of being high in extraction efficiency, short in extraction time, low in cost and small in energy consumption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for extracting cordyceps polysaccharide and adenosine from cordyceps sinensis mycelium

InactiveCN103113442BGood extraction and separation abilitySimple processSugar derivativesSugar derivatives preparationAdenosineKetone

Owner:青海珍赐生物科技有限公司

Extraction method of platinum in high-concentration platinum solution

ActiveCN103468967BShort processReduce processing timeProcess efficiency improvementPlatinumHigh concentration

The invention relates to an extraction method of platinum in a high-concentration platinum solution. The method comprises the following steps of 1) diluting a high-concentration platinum waste dissolving solution with a hydrochloric acid solution with the concentration being 4mol / L; and 2) preparing the platinum solution on which the first-grade extraction is performed by an extraction agent in a dilution manner by taking normal octane as a diluent and N-normal-butyl valnoctamide as a solute and discharging a raffinate so as to obtain an extract containing the platinum. By utilizing the method, the concentration of the platinum in the material solution can be improved to 20g / L; the first-grade extraction rate E is greater than or equal to 99.5%; the technological process is reduced; and the treatment time is shortened. Thus, the method is efficient.

Owner:CHONGQING MATERIALS RES INST

A platinum separation and purification process

ActiveCN108330291BHigh purityEfficient removalProcess efficiency improvementPlatinumReduction treatment

Owner:中宝正信金银珠宝首饰检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com