Method for extracting high-purity cesium carbonate from pollucite

A cesium garnet and cesium carbonate technology, which is applied in the field of extracting high-purity cesium carbonate, can solve problems such as pollution and product purity, and achieve the effects of simple process, less solid waste and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

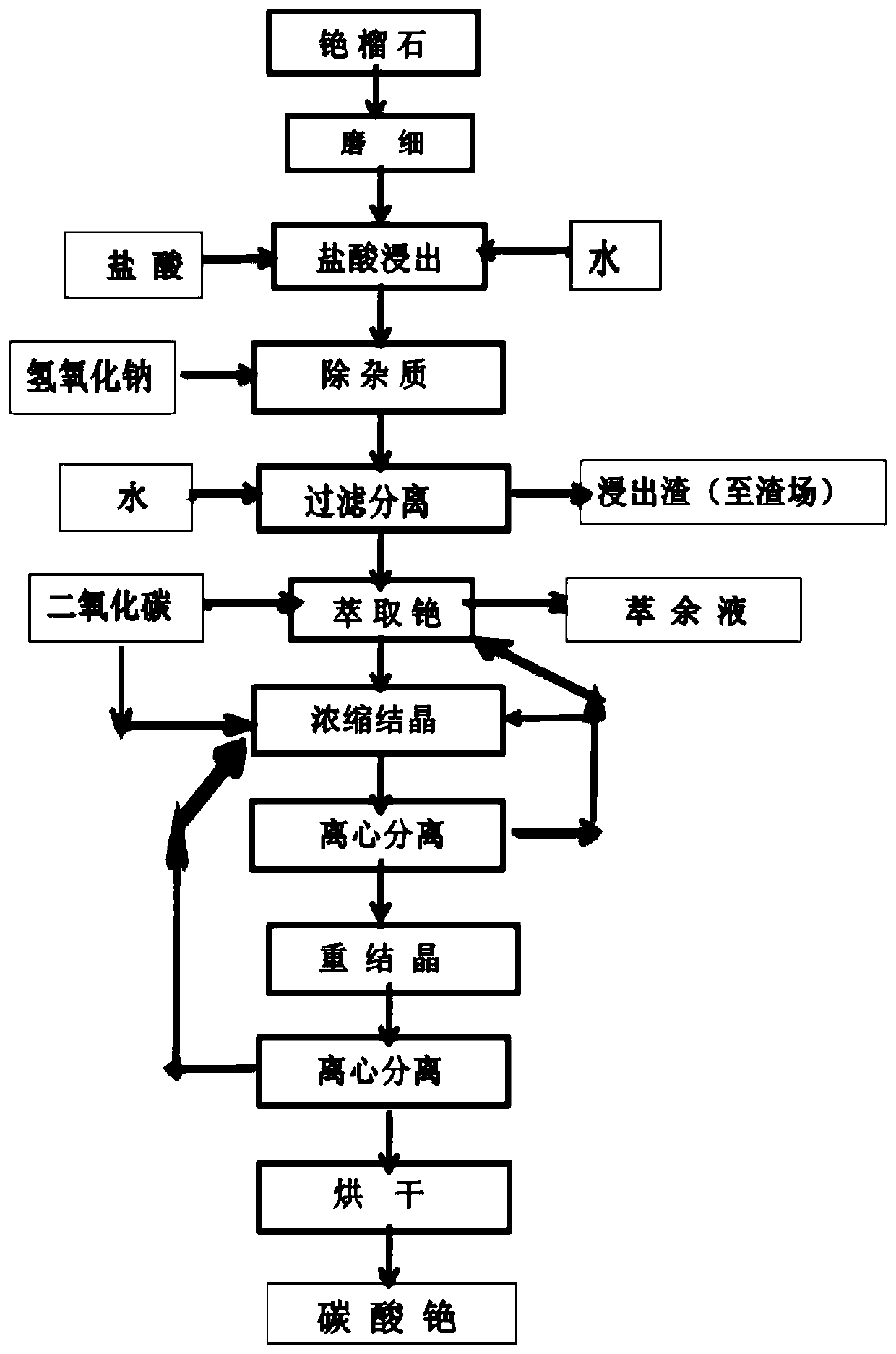

Image

Examples

Embodiment 1

[0037] (1) Ore grinding: grind the ore to 120 mesh with a ball mill.

[0038] (2) Acidification reaction: mix the ground cesium garnet ore powder with 10 equivalents of concentrated hydrochloric acid (concentration: 32%) after step (1), and heat to 100°C in a closed enamel reaction kettle for reaction 2 Hour.

[0039] (3) Add water to the slurry reacted in step (2), mix at a liquid-solid ratio of 4:1, and heat to 80-100°C for leaching reaction for 1 hour.

[0040] (4) adding sodium hydroxide to the material reacted in step (3) to adjust the pH to 10, so as to precipitate impurities such as aluminum, silicon, calcium and magnesium therein.

[0041] (5) Filter the material after step (4) with a filter press, and then wash the slag with water, and the liquid-solid ratio of the slag washing is 1:1.

[0042] (6) After adjusting the components of the leach solution in step (5), enter the continuous mixing and clarification extraction tank to extract with the special extraction age...

Embodiment 2

[0047] (1) Ore grinding: use a ball mill to grind the ore to 160 mesh.

[0048] (2) Acidification reaction: mix the ground cesium garnet ore powder with 12.5 equivalents of concentrated hydrochloric acid (concentration: 32%) after step (1), and heat to 100°C in a closed enamel reaction kettle for reaction 3 Hour.

[0049] (3) Mix the slurry after the reaction in step (2) with slag washing water and a part of low-concentration leaching solution at a liquid-solid ratio of 4:1, and heat to 90°C for leaching reaction for 1 hour.

[0050] (4) adding sodium hydroxide to the material reacted in step (3) to adjust the pH to 10.5, so as to precipitate impurities such as aluminum, silicon, calcium and magnesium therein.

[0051](5) Filter the material after step (4) with a filter press, and then wash the slag with water, and the liquid-solid ratio of the slag washing is 1:1.

[0052] (6) After adjusting the components of the leach solution in step (5), enter the continuous mixing and ...

Embodiment 3

[0057] (1) Ore grinding: grind the ore to 200 mesh with a ball mill.

[0058] (2) Acidification reaction: mix cesium garnet ore powder after step (1) with 13.5 equivalents of concentrated hydrochloric acid (concentration: 32%), and heat to 100°C in a closed enamel reaction kettle for reaction 3.5 Hour.

[0059] (3) Mix the slurry after the reaction in step (2) with slag washing water and part of the low-concentration leaching solution at a liquid-solid ratio of 4:1, and heat to 90°C for leaching reaction for 1 hour.

[0060] (4) adding sodium hydroxide to the reacted material in step (3) to adjust the pH to 11 to precipitate impurities such as aluminum, silicon, calcium, magnesium and the like.

[0061] (5) Filter the material after step (4) with a filter press, and then wash the slag with water, and the liquid-solid ratio of the slag washing is 1:1.

[0062] (6) After adjusting the components of the leach solution in step (5), enter the continuous mixing and clarification e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com