Method of separating lanthanum from rare earth nitrate slurry as well as rare earth ore concentrate separation method

The technology of rare earth nitrate and rare earth feed liquid is applied in the field of rare earth separation technology, and can solve the problems of unattractive commercial application prospect, high price and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

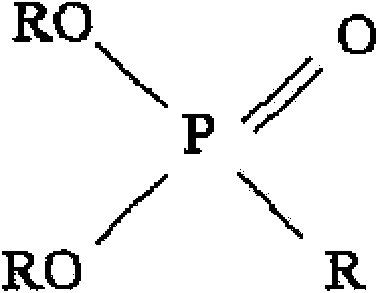

[0073] The method for separating lanthanum from rare earth nitrate feed liquid is as follows:

[0074] (1) Prepare P503 sulfonated kerosene solution with a volume ratio of 30% as the extraction agent, the mass of trivalent mixed rare earth in the rare earth nitrate feed solution is 71g / L rare earth feed solution, and adjust the pH of the feed solution to 2;

[0075] (2) Use 5mol / L sodium nitrate solution as the washing liquid, and use the fractional distillation extraction process for extraction. The number of stages in the extraction section is 5, and the number of stages in the washing section is 10. The flow ratio of the extraction agent, feed liquid and washing liquid is 8:10:2, obtain the raffinate containing lanthanum and the organic phase containing praseodymium and neodymium;

[0076] (3) The stripping liquid is 0.08mol / L sulfuric acid, the flow ratio of the organic phase containing praseodymium and neodymium to the stripping liquid is 0.8:0.2, and it is subjected to 8...

Embodiment 2

[0080] The method for separating lanthanum from rare earth nitrate feed liquid is as follows:

[0081] (1) Prepare a P503 n-heptane solution with a volume ratio of 40% as the extraction agent, the mass of the trivalent mixed rare earth in the rare earth nitrate feed solution is 110g / L rare earth feed solution, and adjust the pH of the feed solution to 2.6;

[0082] (2) Use 0.5mol / L lithium nitrate solution as the lotion, and use the fractional distillation extraction process for extraction. The number of stages in the extraction section is 12, the number of stages in the washing section is 3, and the flow ratio of the extraction agent, feed liquid, and lotion is 10:10:1.5, obtain the raffinate containing lanthanum and the organic phase containing praseodymium and neodymium;

[0083] (3) The back extraction liquid is 0.04mol / L nitric acid, the flow ratio of the organic phase containing praseodymium and neodymium to the back extraction liquid is 1.5:2, and the two-stage counterc...

Embodiment 3

[0087] The method for separating lanthanum from rare earth nitrate feed liquid is as follows:

[0088] (1) Prepare a P503 n-heptane solution with a volume ratio of 50% as the extraction agent, the mass of the trivalent mixed rare earth in the rare earth nitrate feed solution is 130g / L rare earth feed solution, and adjust the pH of the feed solution to 3;

[0089] (2) Use 0.5mol / L lithium nitrate solution as the lotion, and use the fractional distillation extraction process for extraction. The number of stages in the extraction section is 8, and the number of stages in the washing section is 5. The flow ratio of the extraction agent, feed liquid and lotion is 9:10:1.8, obtain the raffinate containing lanthanum and the organic phase containing praseodymium and neodymium;

[0090] (3) The stripping liquid is 0.01mol / L nitric acid, the flow ratio of the organic phase containing praseodymium and neodymium to the stripping liquid is 1.0:1.0, and it is back-extracted in 5 stages, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com