Method for improving divalent metal extraction separation difference

A technology of divalent metal ions and divalent metals, applied in the field of improving the difference in extraction and separation of divalent metals, can solve the problems of ammonia nitrogen wastewater pollution, high cost of sodium saponification, low extraction efficiency, etc., achieve low energy consumption, short extraction time, The effect of high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method utilizing desolvation means to improve the separation difference of divalent metal extraction, said method comprising the following steps:

[0034] first step:

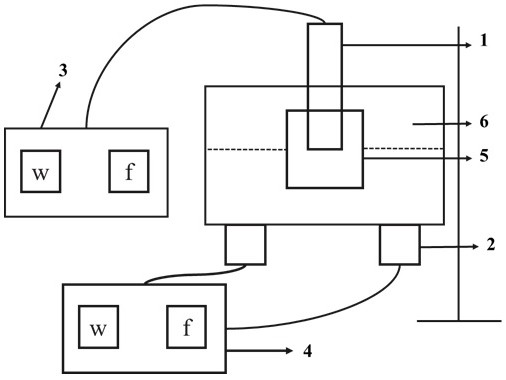

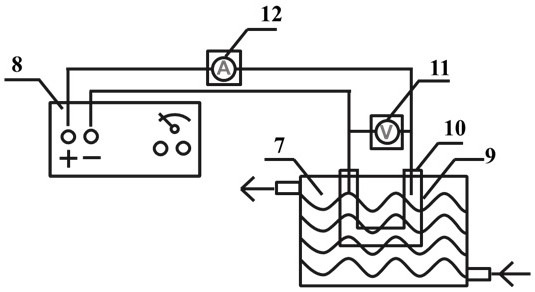

[0035] Build an ultrasonic extraction device, such as figure 1 , add an appropriate amount of water in the tank 6 of the ultrasonic extraction device, the water surface height is 20cm, and the water temperature is adjusted to 25°C. Turn on the ultrasonic generator 3 with a power of 132W to irradiate the tap water inside the device for 10 minutes to remove the bubbles with larger radius in the tap water. Fresh tap water was used in each experiment and the tap water in the device was treated in the above-mentioned manner to ensure that the liquid environment of each experiment was roughly the same.

[0036] Step two:

[0037] Weigh CoSO 4 -7H 2 O and NiSO 4 -6H2 O was dissolved in ultrapure water, respectively, with H 2 SO 4 and NaOH to adjust the pH value of the mixed solution to 5.0 to obtain s...

Embodiment 2

[0058] Carry out extraction test according to the method for embodiment 1, difference is only: metal ion is replaced by nickel and copper, and the power of ultrasonic extraction device is: keep the power of external tank type ultrasonic extractor to be 132W, adjust the power of immersion transducer to be 192W . The irradiation time is 10 minutes, so as to control the energy applied to the system: 115.2kJ / mol nickel or 115.2kJ / mol copper.

[0059] Results: The extraction rate of copper was 72.1%, that of nickel was 2.3%, and the separation coefficient was 31.35.

[0060] Therefore, the use of ultrasonic extraction can also be applied to the separation of nickel and copper.

Embodiment 3

[0073] Carry out extraction test according to the method for embodiment 1, difference is only: metal ion is replaced by nickel and zinc, and the power of ultrasonic extraction device is: keep the power of external tank type ultrasonic extractor to be 132W, adjust the power of immersion transducer to be 168W . The radiation time is 10min. To control the energy applied to the system: 101.3kJ / mol nickel or 101.3kJ / mol zinc.

[0074] Results: The extraction rate of zinc was 98.29%, that of Ni was 1.8%, and the separation coefficient was 54.61.

[0075] Therefore, this ultrasonic extraction method can also be applied to the enhanced separation of nickel and zinc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com