Packed extraction tower, application thereof and residual oil solvent deasphalting method

A technology for extracting solvent and extraction tower, applied in the field of separation equipment, can solve the problems of insufficient separation effect, low mass transfer efficiency, etc., and achieve the effects of avoiding flow dead zone, large liquid flooding flux, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

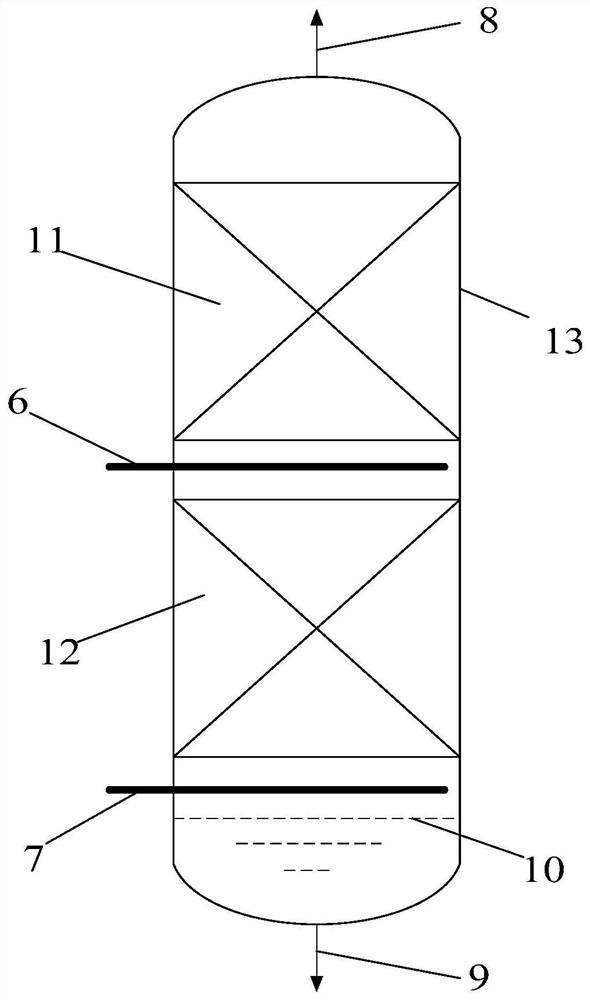

[0030] In one aspect, a packed extraction tower provided by the present invention is composed of a shell, a raw material inlet positioned at the middle of the casing, an extraction solvent inlet positioned at the bottom, an outlet for the extract phase at the top of the tower, an outlet for the raffinate phase at the bottom of the tower, and an extraction structured packing, The extraction structured packing is packed in the shell;

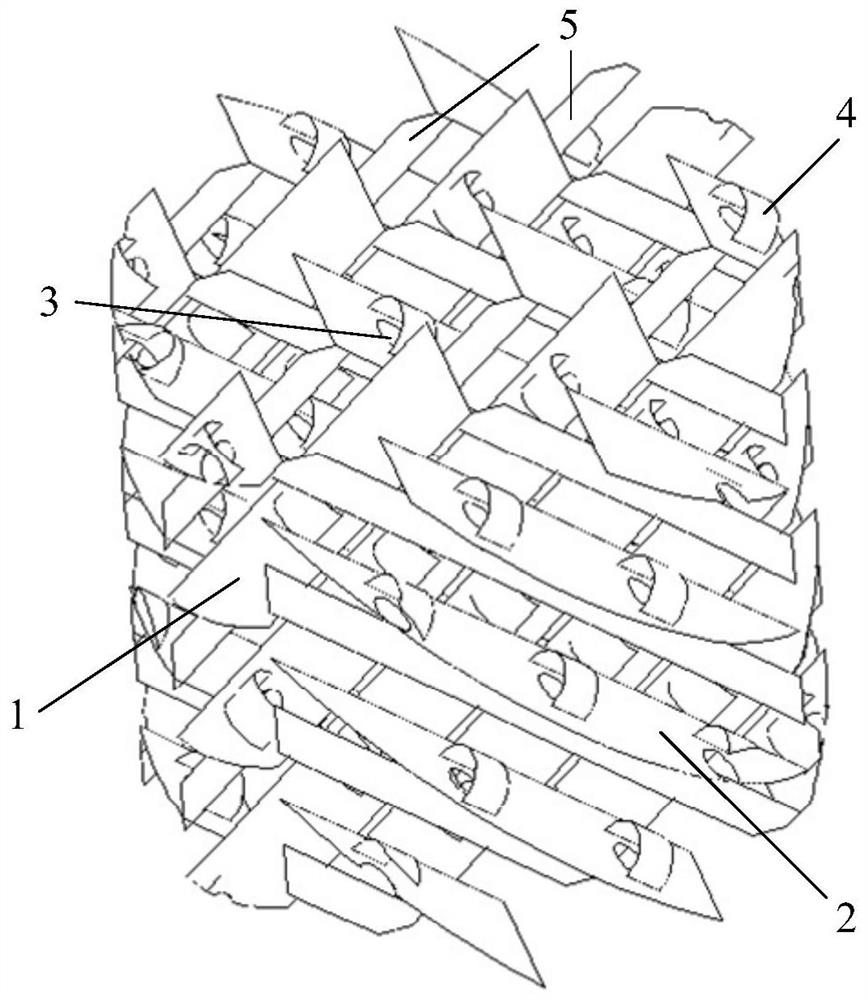

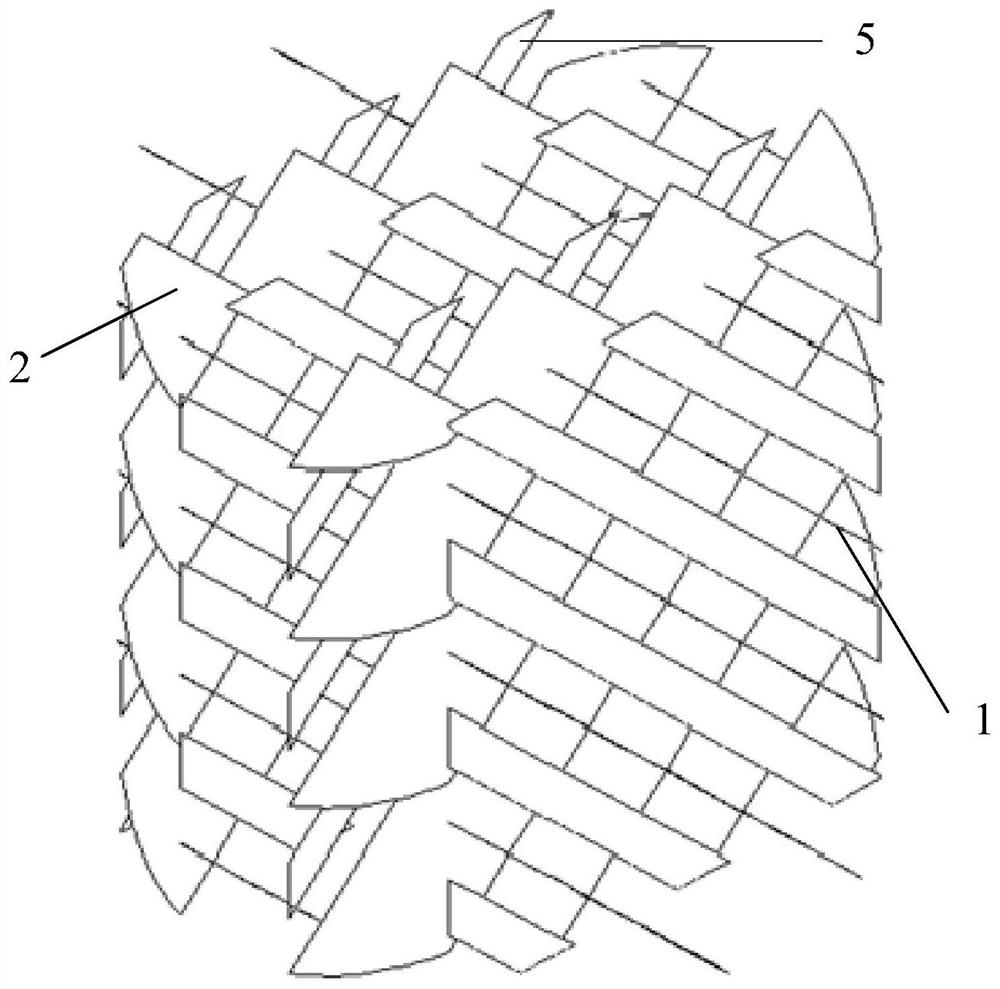

[0031] The extraction structured packing is composed of one or more extraction packing units spliced together; the extraction packing unit is composed of at least two groups of obliquely staggered grid sheet groups, and the angle between adjacent grid sheet groups is 20-120°, The grid sheet group is composed of grid sheets parallel to each other, the angle between the grid sheet and the horizontal plane is 0-90°, and the cross section between the adjacent grid sheet groups is provided with a bar, the bar Parallel to one of the grill sheet groups...

Embodiment 1-4

[0062] Embodiments 1-4 illustrate the effects of the packed extraction tower provided by the invention and the method for solvent deasphalting by thermal model experiments.

[0063] Attached figure 2 For the extraction structured packing shown, there are small holes on the grid sheet of the grid sheet group, the opening rate is 5.7%, the diameter of the small hole is 4mm, the distance between adjacent holes is 20mm, the maximum width of the grid sheet is 10mm, and the thickness The distance between two adjacent grid sheets in the same layer is 10mm. In the same layer, the width of the retaining strip is 4mm, the distance between the retaining strip and two adjacent grid sheets is 3mm, and the retaining strip is located on the cross section formed by the adjacent grid sheet groups. The width of the upper arc of the small hole is 4mm, and the radius is 4mm.

[0064] The structured packing is applied in a solvent deasphalting extraction tower, the diameter of the extraction to...

Embodiment 2

[0069] The raw material that adopts, experimental procedure, process condition are identical with embodiment 1, and the extraction tower structure that adopts is substantially identical with the extraction tower in embodiment 1, and difference is that coalescing packing section is not set in the extraction tower.

[0070] The experimental data show that the yield of deasphalted oil is 64.9%, and its properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com