Dephenolization treatment method for coking residual ammonia wastewater

A technology for coking residual ammonia water and treatment methods, which is applied in the field of environmental protection treatment in the coking industry. It can solve the problems of complex post-processing procedures and large residual ammonia water treatment volume, reduce the difficulty of stripping treatment, reduce sewage output, and increase recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

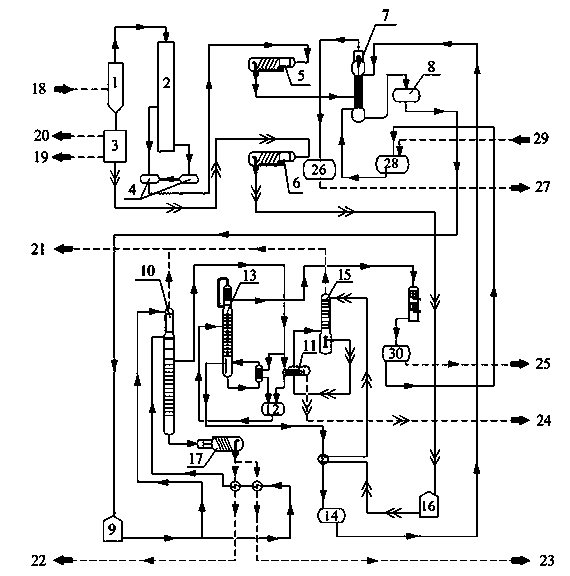

[0048] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0049] A kind of dephenolization processing method of coking residual ammonia water, such as figure 1 As shown, the raw coal gas is cooled by spraying circulating ammonia water in the gas collecting pipe, and enters the gas-liquid separator 1 through the raw coal gas input pipeline 18, and the residual ammonia water and residual gas of fixed ammonium are separated. The residual ammonia water of fixed ammonium enters the fixed ammonium dephenolization treatment unit for post-treatment, and the remaining gas continues to enter the gas primary cooler 2 for cooling to obtain the residual ammonia water of free ammonia, which is temporarily stored in the condensation tank 4 of the primary gas cooler, and then Enter the free ammonia dephenolization treatment unit for post-treatment.

[0050] (1) Post-treatment of residual ammonia water after immobilizing ammonium

[0051] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com