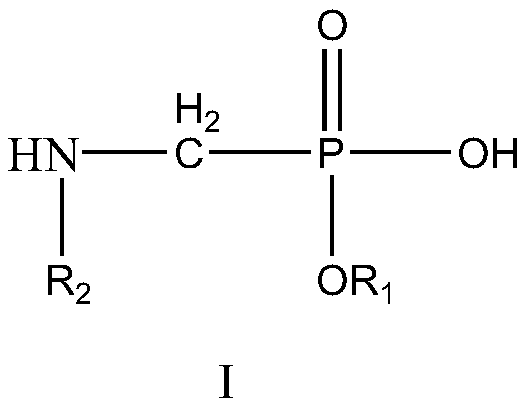

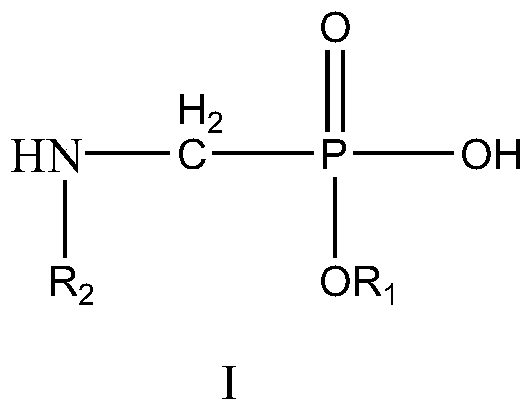

Use and method of amino acid-containing phosphine extractant for extracting and separating cobalt and nickel

A technology of amino acid and extractant, applied in the direction of improving process efficiency, etc., can solve the problems of difficult separation of sulfate solution, large loss of extractant, small separation coefficient, etc., achieve good separation effect, reduce separation cost, and have stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

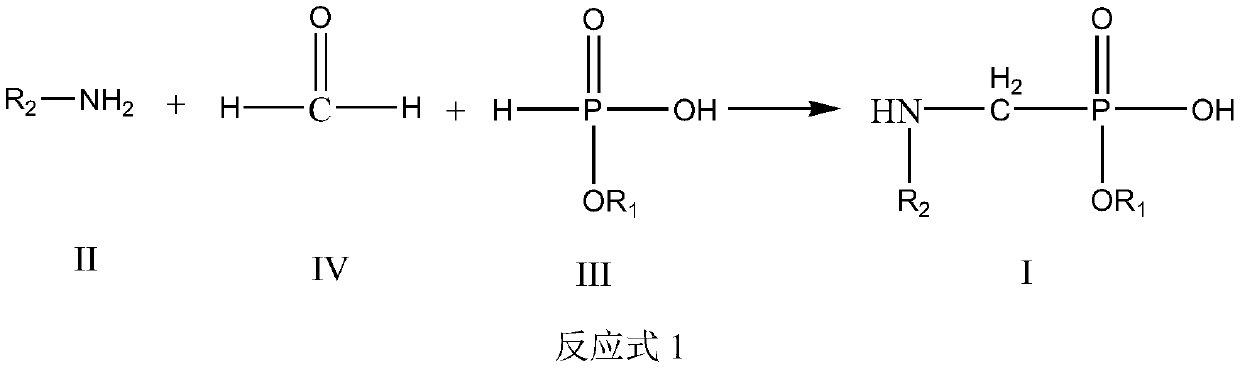

Method used

Image

Examples

Embodiment 1

[0092] Preparation of the organic phase: Mix 3L 1-(2-ethylhexylamino)methylphosphonic acid mono(2-ethylhexyl)ester with 7L sulfonated kerosene, then add sodium hydroxide solid to saponify at a degree of saponification of 40% , to obtain the organic phase.

[0093] The feed liquid is a mixed solution of cobalt and nickel chloride, wherein the concentration of cobalt is 0.2 mol / L, and the concentration of nickel is 0.2 mol / L; the pH of the feed liquid is 5.0.

[0094] The washing solution is 0.2mol / L hydrochloric acid solution.

[0095] The stripping agent is 1.0mol / L hydrochloric acid solution.

[0096] The organic phase and the feed liquid are mixed at a ratio of 1:1 by volume to perform 10-stage countercurrent extraction to obtain a nickel-containing extract and a cobalt-containing raffinate aqueous phase. Then, the nickel-containing extraction solution and the washing solution are mixed at a volume ratio of 10:1 for two-stage countercurrent washing, and the resulting washi...

Embodiment 2

[0104] Mix 3L 1-(2-methylhexylamino)methylphosphonic acid mono(2-ethylhexyl)ester, 1L methylheptanol and 6L aviation kerosene, then add NaOH for saponification according to the degree of saponification of 30%, to obtain organic Mutually.

[0105] The feed liquid is a mixed solution of cobalt and nickel sulfate, wherein the concentration of cobalt is 0.5 mol / L, and the concentration of nickel is 0.1 mol / L; the pH of the feed liquid is 5.5.

[0106] The detergent is water.

[0107] Stripping agent is [H 2 SO 4 ]=1.0mol / L sulfuric acid solution.

[0108] The organic phase and the feed liquid are mixed at a ratio of 1:2 by volume to perform 20-stage countercurrent extraction to obtain a nickel-containing extract and a cobalt-containing raffinate aqueous phase. Then, the nickel-containing extract and washing liquid are mixed at a volume ratio of 6:1 for 10-stage countercurrent washing, and the resulting washing liquid is circulated back to the extraction section for the extract...

Embodiment 3

[0116] Mix 3L of 1-(2-propylpentylamino)methylphosphonic acid mono(2-ethylhexyl)ester with 7L of aviation kerosene, then add sodium hydroxide for saponification according to the degree of saponification of 25%, to obtain an organic phase.

[0117] The feed liquid is a mixed solution of cobalt-nickel nitrate, wherein the concentration of cobalt is 0.05 mol / L, and the concentration of nickel is 0.5 mol / L; the pH of the feed liquid is 4.8.

[0118] The stripping agent is 0.5mol / L nitric acid solution.

[0119] The organic phase was mixed with the volume ratio of solid to liquid at a ratio of 3:1 to perform one-stage countercurrent extraction to obtain a nickel-containing extract and a cobalt-containing raffinate aqueous phase. Then, the nickel-containing extract and the stripping agent are directly subjected to 5-stage countercurrent stripping at a volume ratio of 20:1 to obtain a nickel-containing aqueous solution.

[0120] Elemental analysis was carried out on the obtained nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com