a centrifugal extractor

An extractor and centrosymmetric technology, which is applied in the field of centrifugal extractors, can solve problems such as increased difficulty in debugging, inconvenient maintenance, and complicated processing technology, and achieves the effects of reasonable structural design, convenient dynamic balance, and good dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples are used to describe the present invention in detail, which are only used to further explain the present invention and cannot be understood as limiting the scope of protection of the present invention. Technical engineers in this field can make some non-essential improvements to the present invention based on the content of the above-mentioned invention. And adjustment.

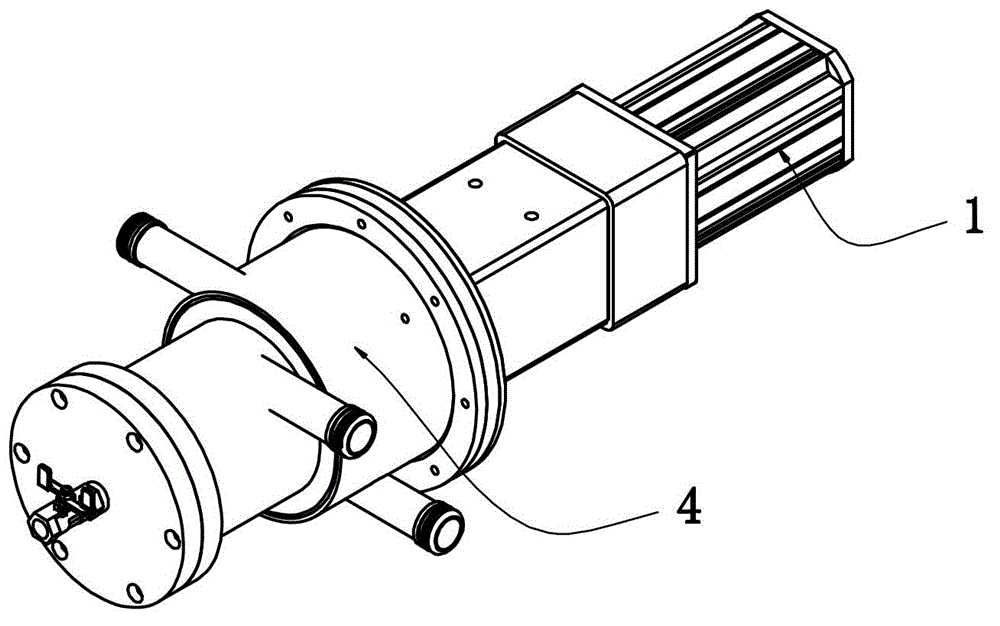

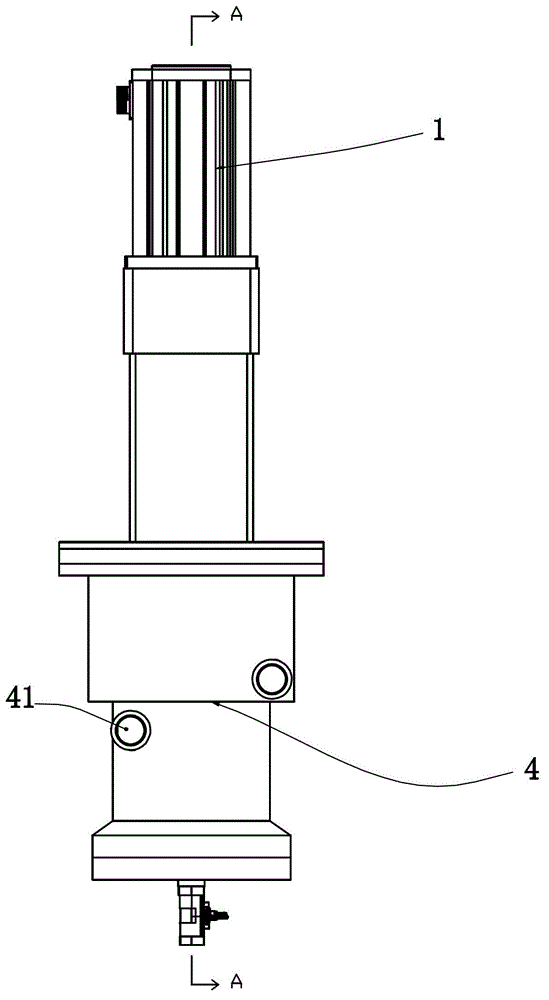

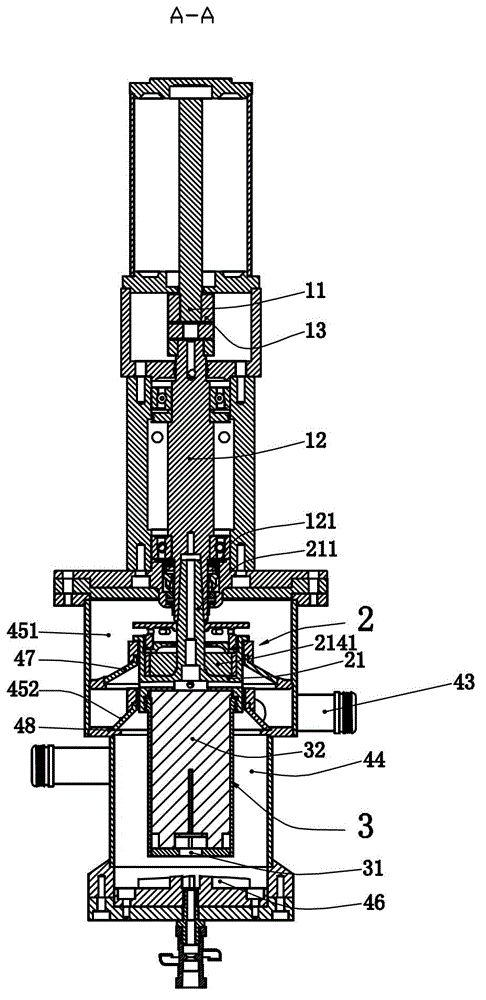

[0039] Such as Figure 1-11 The specific embodiment of the present invention shown includes a motor 1, a fluid guide assembly 2, a rotating drum 3, and a housing 4. The motor 1 is coaxially connected to the fluid guide assembly 2, and the fluid guide assembly 2 is connected to the rotating The drum 3 is fixed and connected by coaxial transmission. The fluid guide assembly 2 and the rotating drum 3 are both rotatably arranged in the housing. The housing 4 is provided with a material inlet 41, a heavy phase outlet 42 and a light phase outlet 43. This embodiment The material inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com