Method for preventing interfacial crud during vanadium-chromium extraction and separation

A technology for separation process and interface contamination, applied in the direction of process efficiency improvement, etc., can solve the problems of inability to fundamentally eliminate interface contamination, little research on vanadium-chromium separation, and few industrialized examples, etc., to prevent interface contamination, The effect of saving labor and equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

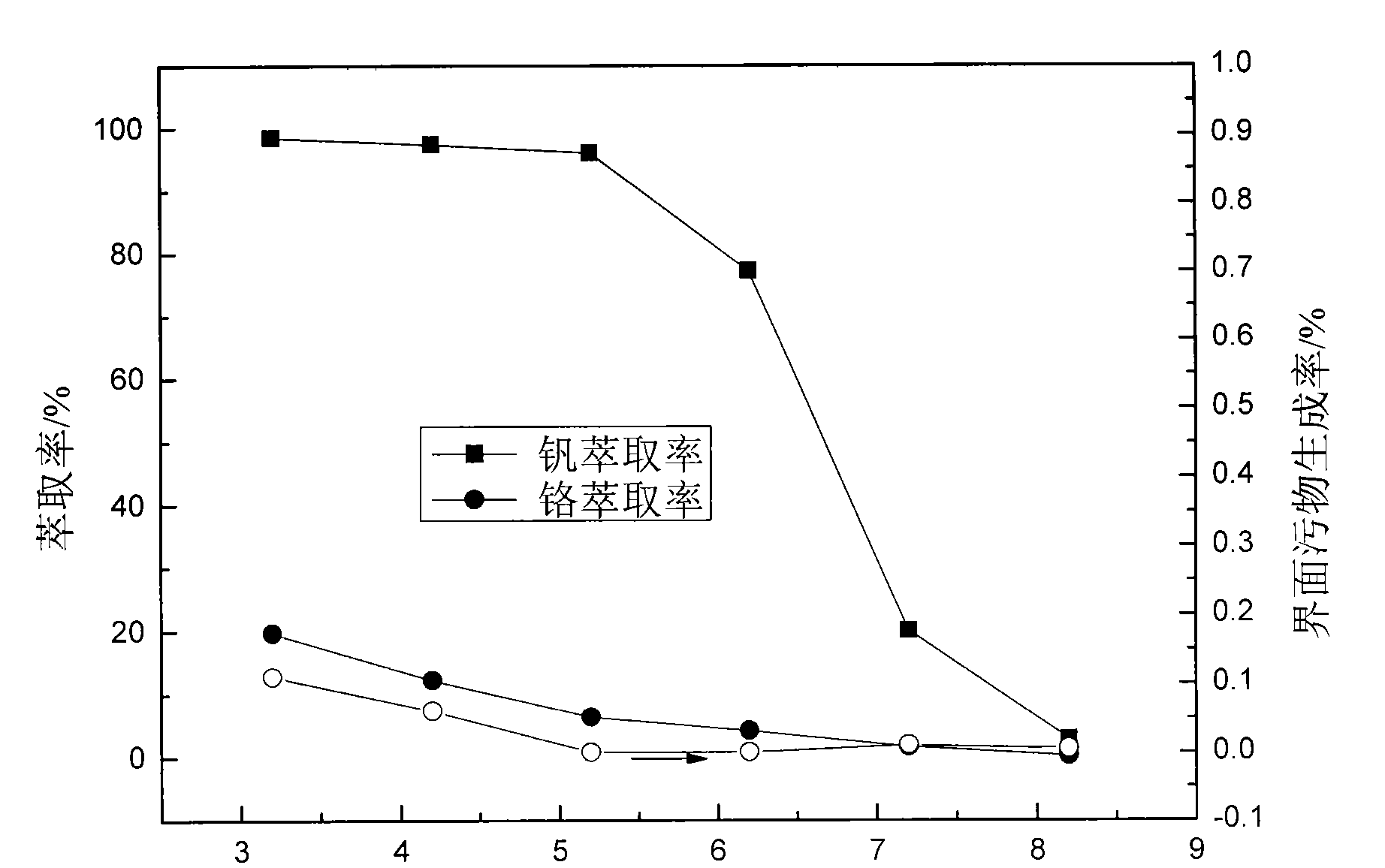

Embodiment 1

[0023] The chromium-containing vanadium slag leaching liquid was used as the extraction liquid, and the primary amine extractant N1923 and the diluent cyclohexane were used to make the organic phase, and the extraction separation test was carried out, and the pH values of the feed liquid were adjusted to 3.20, 4.20, 5.20, 6.20, 7.20, 8.20, the volume concentration of the extractant is selected to be 15% (v / v), the extraction temperature is room temperature (25°C), the aqueous phase and the organic phase are mixed in a separatory funnel, and then the separatory funnel is fixed on the Conrad shaker Vibrate for 5 minutes, remove the shaker and let the layers stand for 30 minutes, then take out the interface dirt between the aqueous phase and the organic phase, measure the volume of the interface dirt with a graduated cylinder of appropriate specifications, and then use the volume of the measured interface dirt to divide The sum of the volumes of the initial aqueous phase and t...

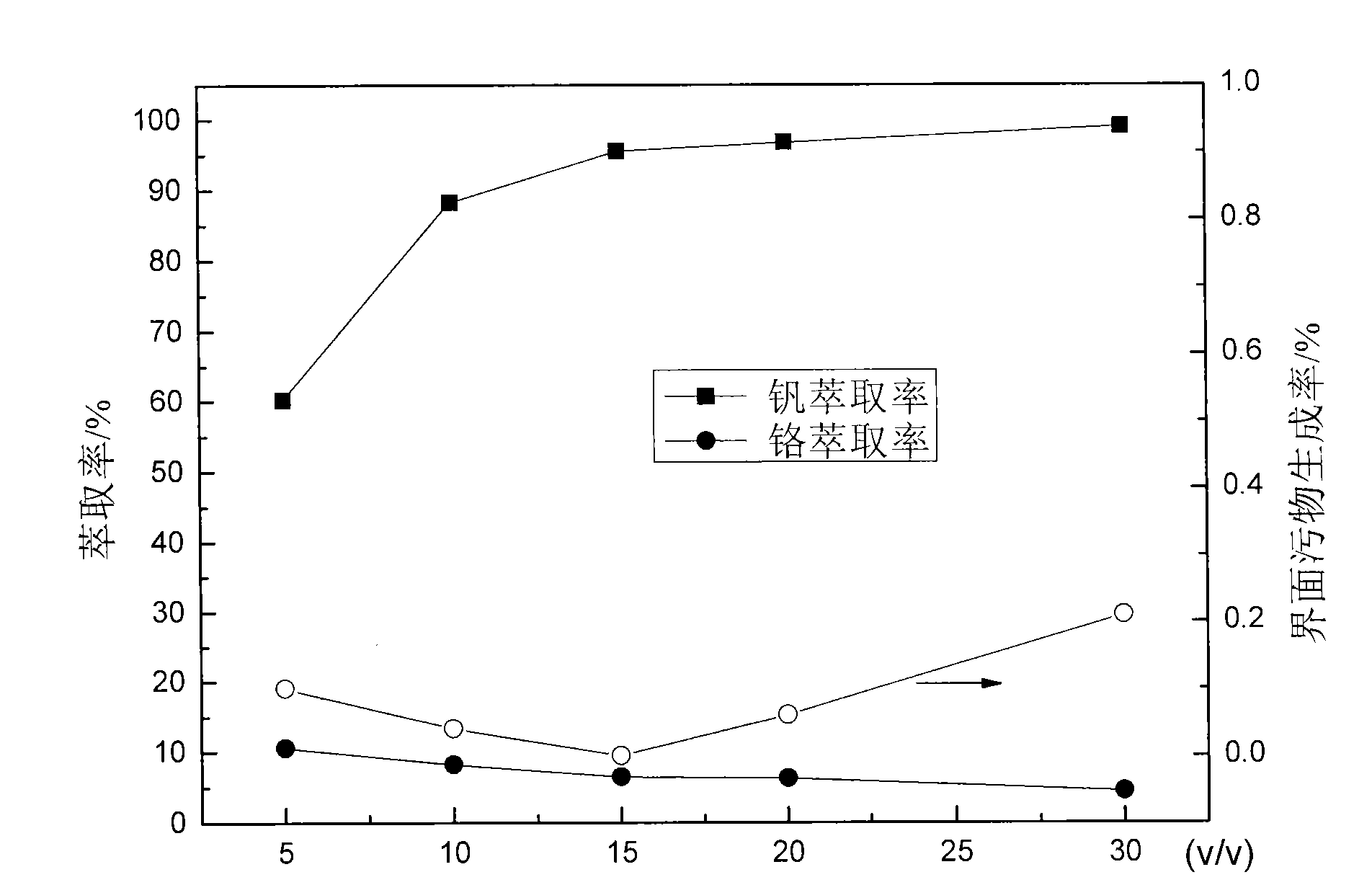

Embodiment 2

[0025] Using the chromium-containing vanadium slag leaching liquid as the extraction liquid, the primary amine extractant N1923 and the diluent cyclohexane were used to form the organic phase, and the extraction separation test was carried out, wherein the pH value of the feed liquid was adjusted to 5.20, and the volume concentration of the extractant was selected as (v / v) 5%, 10%, 15%, 20%, 30%, 40%, the extraction temperature is room temperature (25°C), the aqueous phase and the organic phase are mixed in a separatory funnel, and then the separatory funnel is fixed on Shake for 5 minutes on the Consonian oscillator, remove the oscillator and let the layers stand for 30 minutes, then take out the dirt at the interface between the aqueous phase and the organic phase, measure the volume of the dirt at the interface with a graduated cylinder of appropriate specifications, and then use the measured interface Divide the volume of the dirt by the sum of the volumes of the initial a...

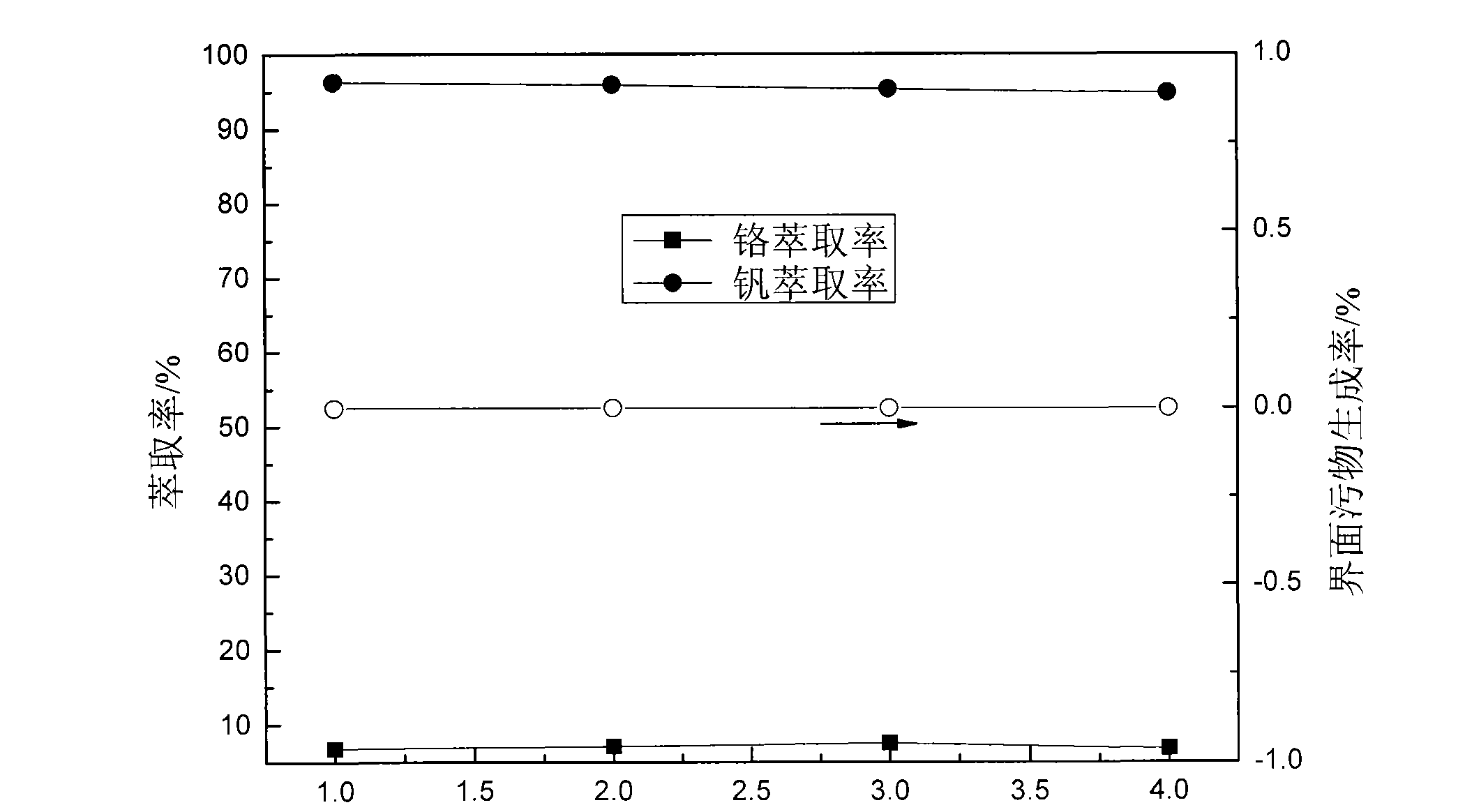

Embodiment 3

[0027] The leaching solution of chromium-containing vanadium slag was used as the extraction liquid, and the organic phase was prepared with the primary amine extractant N1923 and the diluent, and the extraction and separation test was carried out. The value is 5.20, the extractant volume concentration is selected as 15% (v / v), and the extraction temperature is room temperature (25° C.), the aqueous phase and the organic phase are mixed in a separating funnel, and then the separating funnel is fixed on a Kang’s vibration Shake on the shaker for 5 minutes, take off the shaker and let the layers stand for 30 minutes, then take out the interface dirt between the aqueous phase and the organic phase, use a graduated cylinder of appropriate specifications to measure the volume of the interface dirt, and then use the volume of the measured interface dirt Divide the volume by the sum of the volume of the initial aqueous phase and the organic phase, and record it as the generation rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com