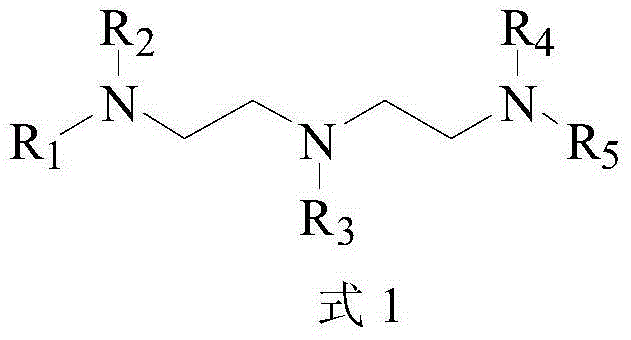

Pentaalkyl-diethylene-tri-tert-amine and its preparation method and use

A technology of pentaalkyl diethylene and tritertiary amine, applied in the field of metallurgy, can solve the problems of high cost, poor selectivity, high price, etc., and achieve the effects of simple operation, mild reaction conditions, and good extraction and separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

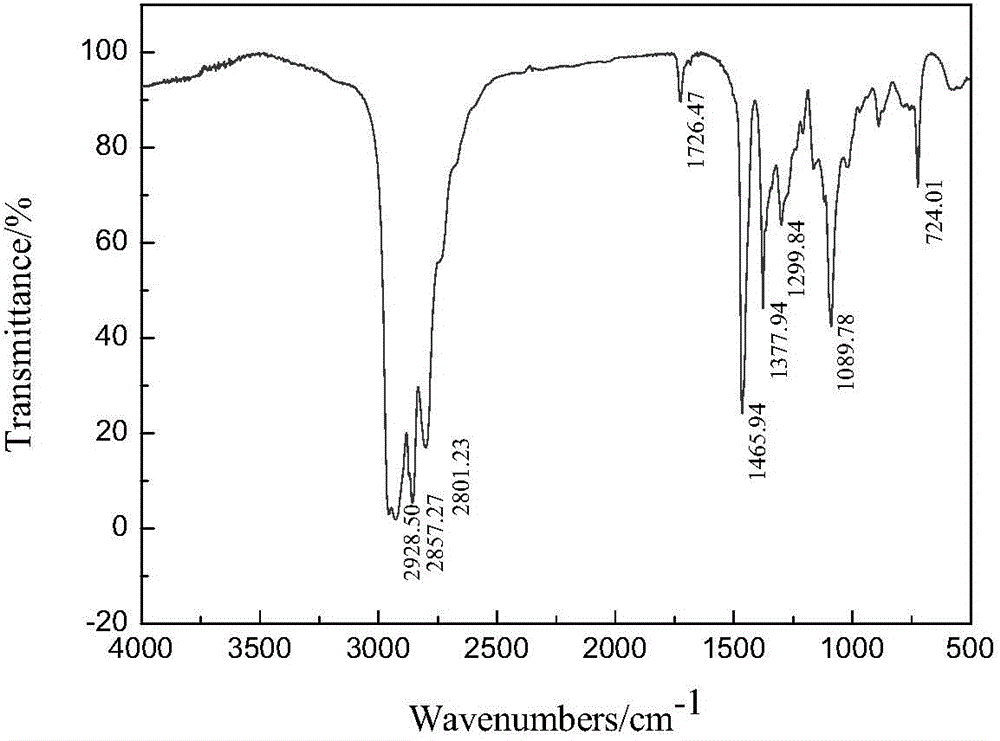

[0031] In a 250mL three-necked flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 0.1mol of diethylenetriamine, 0.5mol of anhydrous potassium carbonate, and 50mL of absolute ethanol, start the stirrer, heat, and keep the reaction temperature at 75 After ℃, start to add 0.5mol n-bromohexane dropwise, the dropping rate is 20-30 drops / min, stop after 12 hours of reaction, cool down, the mixture is filtered to obtain a bright yellow transparent solution, and distilled under reduced pressure to remove ethanol and a small amount of unreacted Bromo-n-hexane obtains the product after vacuum distillation, and the product after vacuum distillation is washed with 10% sodium hydroxide by mass fraction, and the solution is divided into three layers, the upper layer is a yellow oily liquid, the middle layer is reddish brown, and the lower layer is a colorless transparent liquid. Take out the middle and lower layers, add cyclohexane to extract three times, 5 mL each...

Embodiment 2

[0034] The feed liquid is pure molybdenum feed liquid in which ammonium molybdate is dissolved in deionized water, containing 4.93g L of molybdenum -1 , adjusted to pH=3 with sulfuric acid.

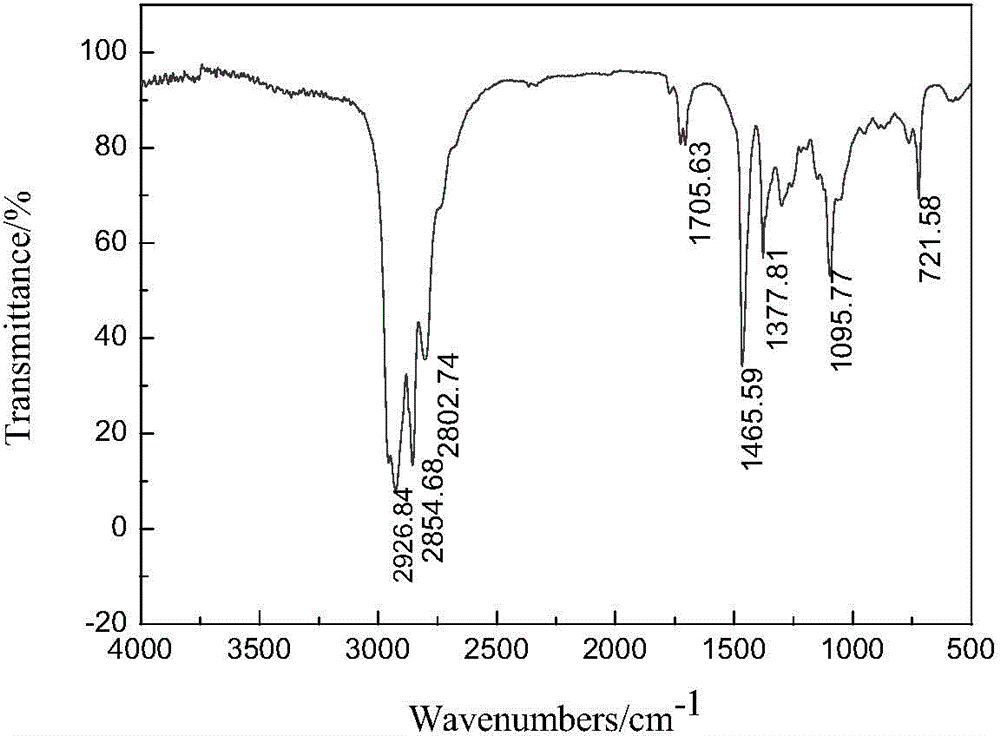

[0035] Organic phase: prepare four organic phases with numbers 1, 2, 3, and 4, the extractant of the organic phase is N, N, N', N", N"-pentahexyldiethylenetriamine, and the diluent is sulfonated Kerosene, the modifier is 2-octyl alcohol, the volume ratio of fixed 2-octanol to sulfonated kerosene is 1:2, and the No. 1 organic phase is 1% N,N,N',N",N"-pentahexyldiethylenetri Amine, 3% by volume of organic phase No. 2 N,N,N',N",N"-Pentahexyldiethylenetriamine, 5% by volume of organic phase No. 3N,N,N',N",N",N" - Pentahexyldiethylenetriamine, organic phase No. 4 is 7% by volume N,N,N',N",N"-pentahexyldiethylenetriamine.

[0036] The above four organic phases were acidified with sulfuric acid and then subjected to single-stage extraction under the condition of O / A (volume ratio of organic ph...

Embodiment 3

[0041] The feed liquid is a synthetic feed liquid in the laboratory, containing Mo 4.416g L -1 , Fe 2+ (Fe 3+ )1.119g L -1 、Ni 2+ 2.06g·L -1 , P 1.481g·L -1 , adjust the pH to 1.5 with sulfuric acid.

[0042] The composition of the organic phase is 7% by volume N,N,N',N",N"-pentahexyldiethylenetriamine + 31% by volume 2-octanol + 62% by volume sulfonated kerosene, after acidification with sulfuric acid, in O / A =1 / 4 for single-stage extraction, the temperature is 25°C, and the extraction time is 10min. The experimental results are shown in Table 2.

[0043] Table 2 N, N, N', N", N"-Pentahexyldiethylenetriamine Selective Extraction and Separation Effect of Molybdenum

[0044] the element

[0045] As shown in Table 2, the extraction rate of organic relative molybdenum is relatively high, but nickel is not extracted, so a higher separation effect of molybdenum and nickel can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com