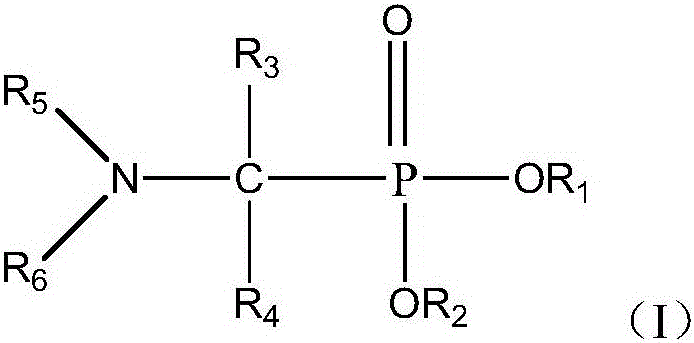

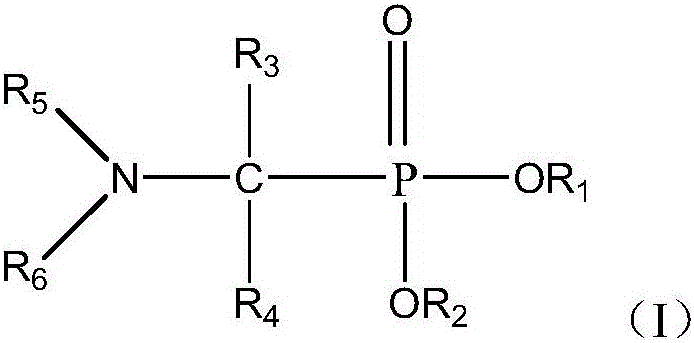

Purpose and method of amido-contained neutral phosphine extracting agent for extracting and separating zirconium and/or hafnium

A neutral phosphine and extractant technology, applied in the field of amino neutral phosphine extractant, extraction and separation of zirconium and/or hafnium, can solve the problems of tributyl phosphate emulsification, severe equipment corrosion, HSCN pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

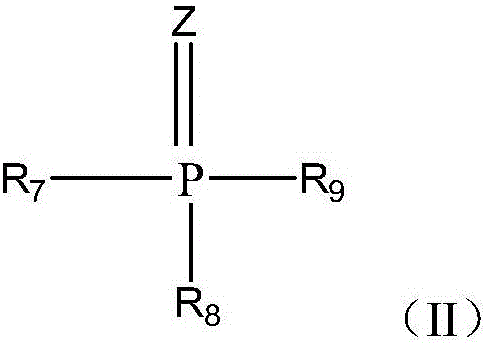

Method used

Image

Examples

Embodiment 1

[0131] Preparation of the organic phase: Mix 3L of 1-(2-ethylhexylamino)methyl bis(2-ethylhexyl)phosphonate with 7L of aviation kerosene to prepare the organic phase.

[0132] Feed liquid is the mixed solution of zirconium sulfate, wherein the concentration of zirconium is 0.2mol / L; Acidity is 1.5mol / L,

[0133] The washing solution is 0.5mol / L sulfuric acid solution.

[0134] The stripping agent is 1.0mol / L ammonia solution.

[0135] A 250ml mixed-clarified extraction tank was used for extraction and separation experiments. First, 20 stages of countercurrent extraction are carried out, and the flow ratio of the organic phase to the feed liquid is 10mL / min: 15mL / min to obtain a zirconium-containing extract. Then carry out 5 stages of countercurrent washing, the flow ratio of the zirconium-containing extract solution to the washing solution is 10mL / min: 5mL / min. Then carry out 5-stage countercurrent back extraction, the flow ratio of zirconium-containing extract solution and...

Embodiment 2

[0137] Preparation of the organic phase: 3 L of 1-(2-ethylhexylamino)ethylphosphonic acid bis(2-ethylhexyl) ester, 1 L of 2-methylheptanol and 6 L of aviation kerosene were mixed to prepare an organic phase.

[0138] The feed liquid is a mixed solution of zirconium and hafnium sulfate, wherein the concentration of zirconium is 0.2mol / L; the concentration of hafnium is 0.004mol / L; the acidity is 1.5mol / L,

[0139] The washing solution is 1.0mol / L hydrochloric acid solution.

[0140] The stripping agent is 1.0mol / L sodium hydroxide solution.

[0141] A 250ml mixed-clarified extraction tank was used for extraction and separation experiments. Firstly, 20 stages of countercurrent extraction are carried out, and the flow ratio of the organic phase to the feed liquid is 10mL / min: 15mL / min to obtain a zirconium-containing extract and a hafnium-containing tail liquid. Then carry out 7 stages of countercurrent washing, the flow ratio of the zirconium-containing extract solution to the...

Embodiment 3

[0143] Preparation of the organic phase: 3 L of 1-(2-ethylhexylamino) 1-methylethylphosphonic acid bis(2-ethylhexyl) ester was mixed with 7 L of aviation kerosene to prepare an organic phase.

[0144] The feed liquid is a mixed solution of zirconium and hafnium nitrate, wherein the concentration of zirconium is 0.5mol / L; the concentration of hafnium is 0.04mol / L; the acidity is 1.5mol / L,

[0145] The washing solution is 1.0mol / L nitric acid solution.

[0146] The stripping agent is 4.0mol / L nitric acid solution.

[0147] A 250ml mixed-clarified extraction tank was used for extraction and separation experiments. Firstly, 20 stages of countercurrent extraction are carried out, and the flow ratio of the organic phase to the feed liquid is 20mL / min: 10mL / min to obtain a zirconium-containing extract and a hafnium-containing tail liquid. Then carry out 7 stages of countercurrent washing, the flow ratio of the zirconium-containing extract solution to the washing solution is 20mL / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com