Condensate type fuel gas fast water heater

A technology for condensing heat exchangers and water heaters, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc., and can solve the problems of reduced heat exchange efficiency of heat exchange bodies, high requirements for process assurance, water leakage of condensing heat exchangers, etc. problems, achieving the effect of eliminating the need for welding processes, reducing manufacturing costs, and simplifying the waterway structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

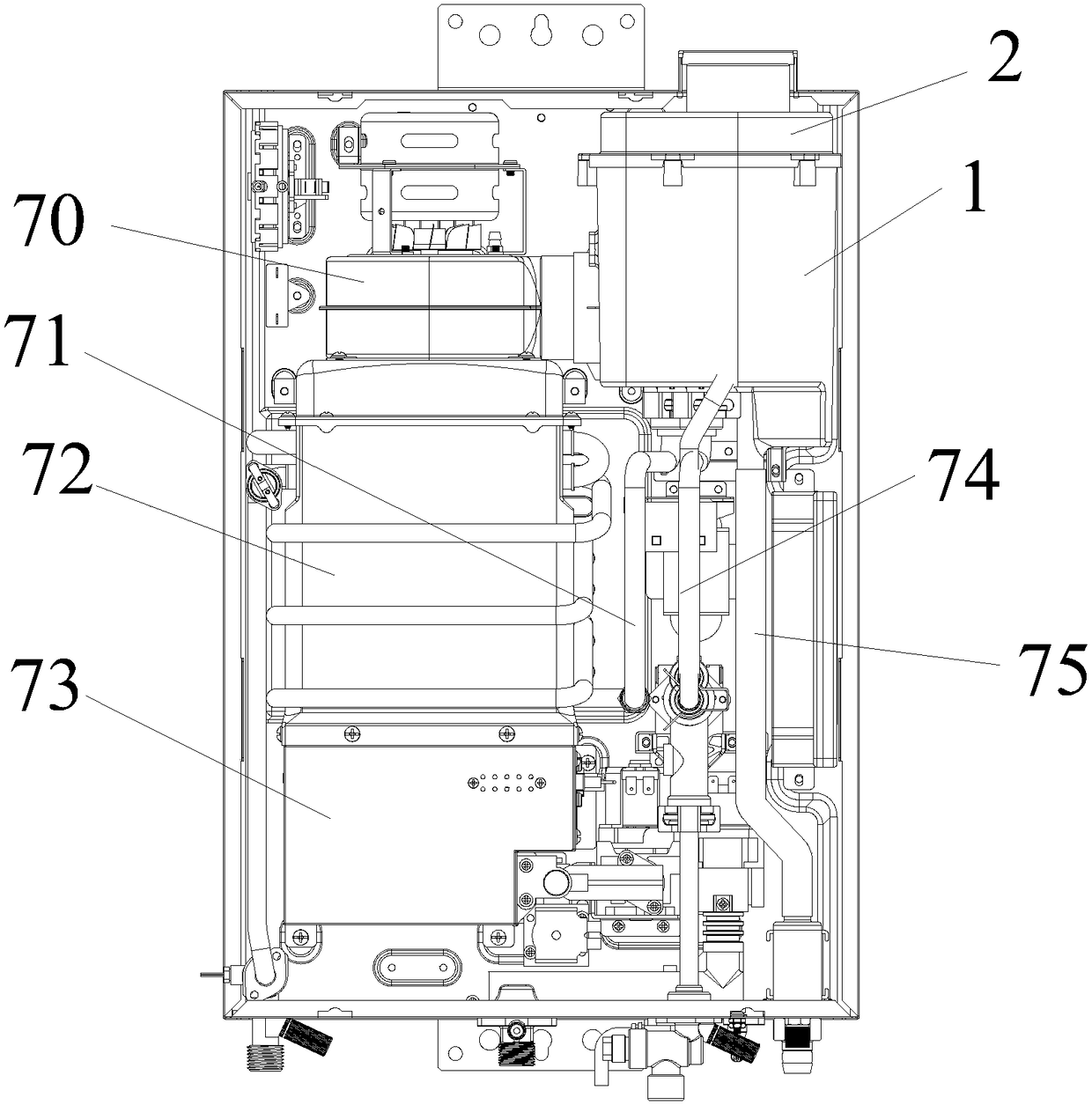

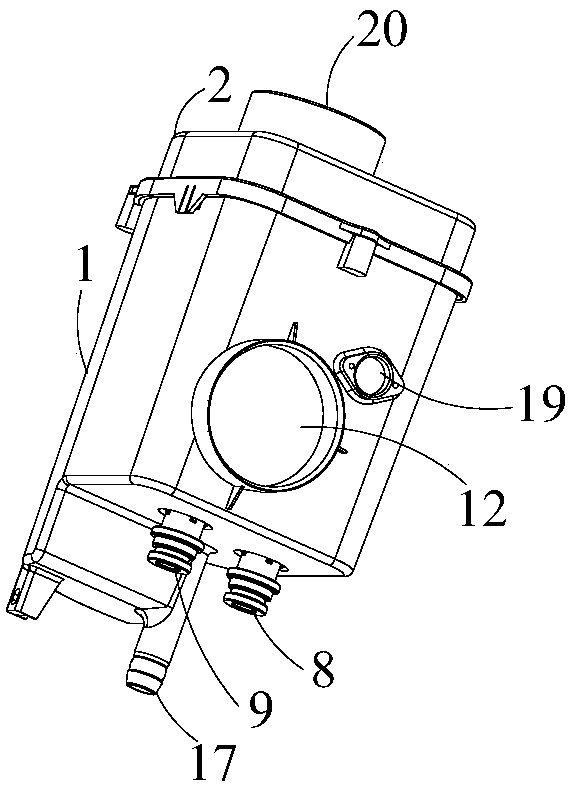

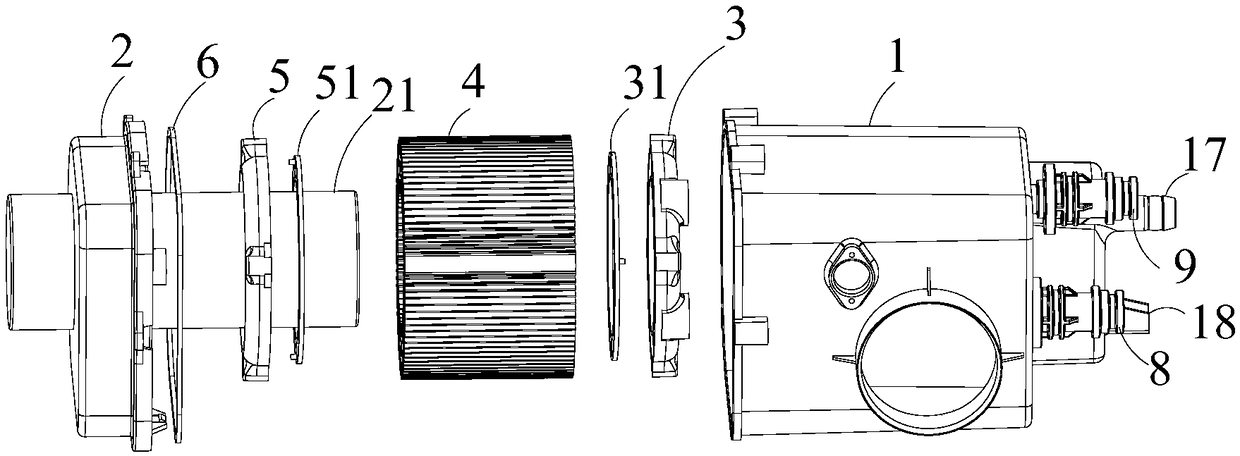

[0057] see first Figure 1-6 A condensing gas instant water heater includes a burner 73, a main heat exchanger 72 arranged above the burner 73, and a fan 70 arranged above the main heat exchanger 72, and the fan 70 is connected to the casing 1 for condensing heat exchange, so that The flue gas from the main heat exchanger 72 enters the condensing heat exchanger. The water outlet joint 9 of the condensing heat exchanger is connected to the water inlet pipe of the main heat exchanger 72 through the water outlet pipe 71, and the water inlet joint 8 is connected to the water inlet pipe 74 of the water heater, so that the water flow enters the condensing heat exchanger, and the condensing pipe 75 is connected to the shell 1 The condensed water outlet 17 is used to discharge the condensed water out of the water heater. Of course, the water heater of the present invention also includes other necessary components to realize the function of the water heater, but the main invention of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com