Automobile air window

A technology for ventilation windows and automobiles, which is applied to vehicle components, superstructures, roofs, etc., can solve problems such as water leakage from skylights, reduced wind pressure, and insufficient ventilation, and achieves increased ventilation, reduced noise, and increased emissions. Effect of wind area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

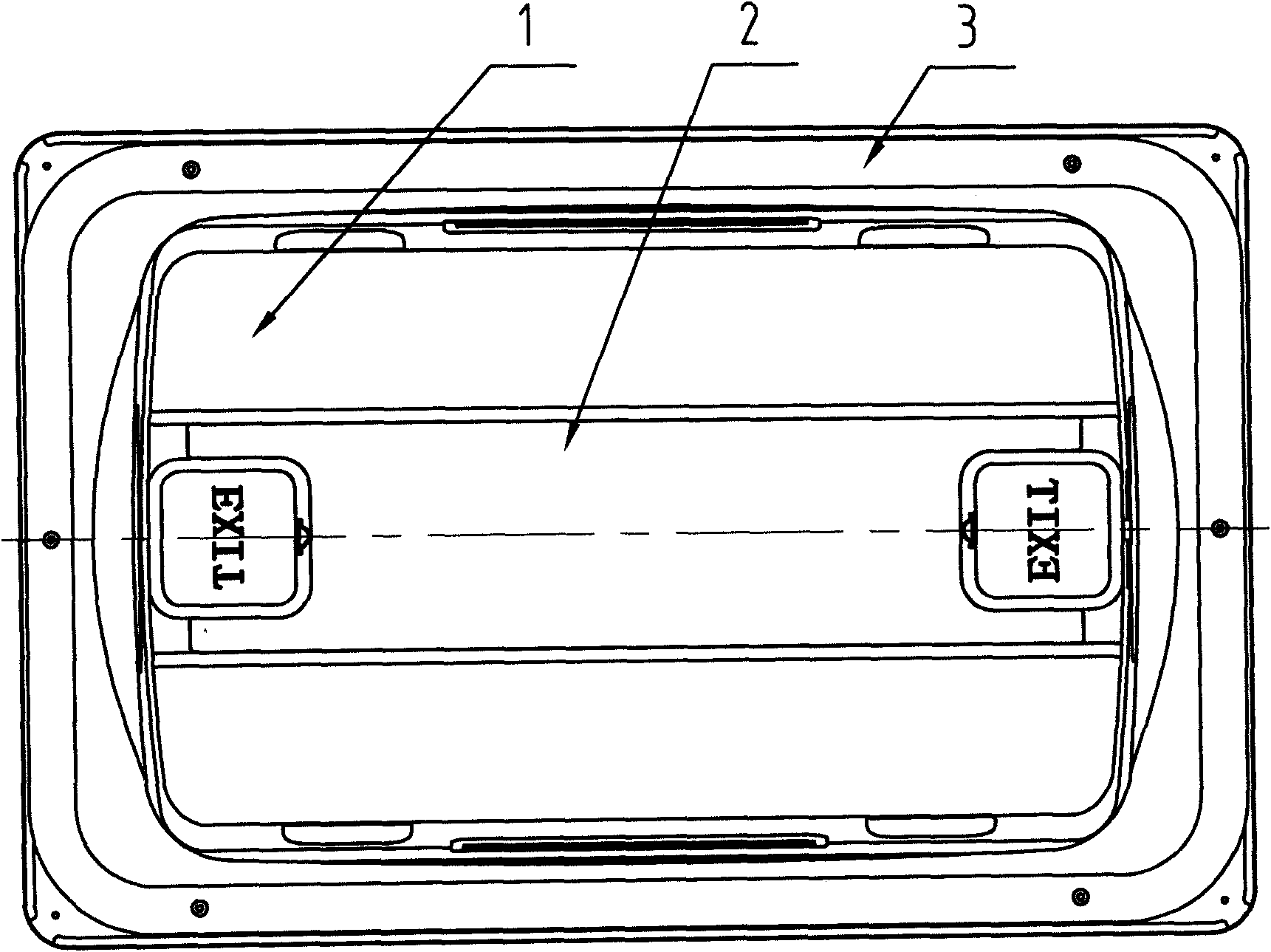

[0023] Depend on figure 1 Known, is the front view of the automobile ventilation window of the present embodiment, including the inner cover 1, the subframe 3, the decorative cover 2, and the top cover 4.

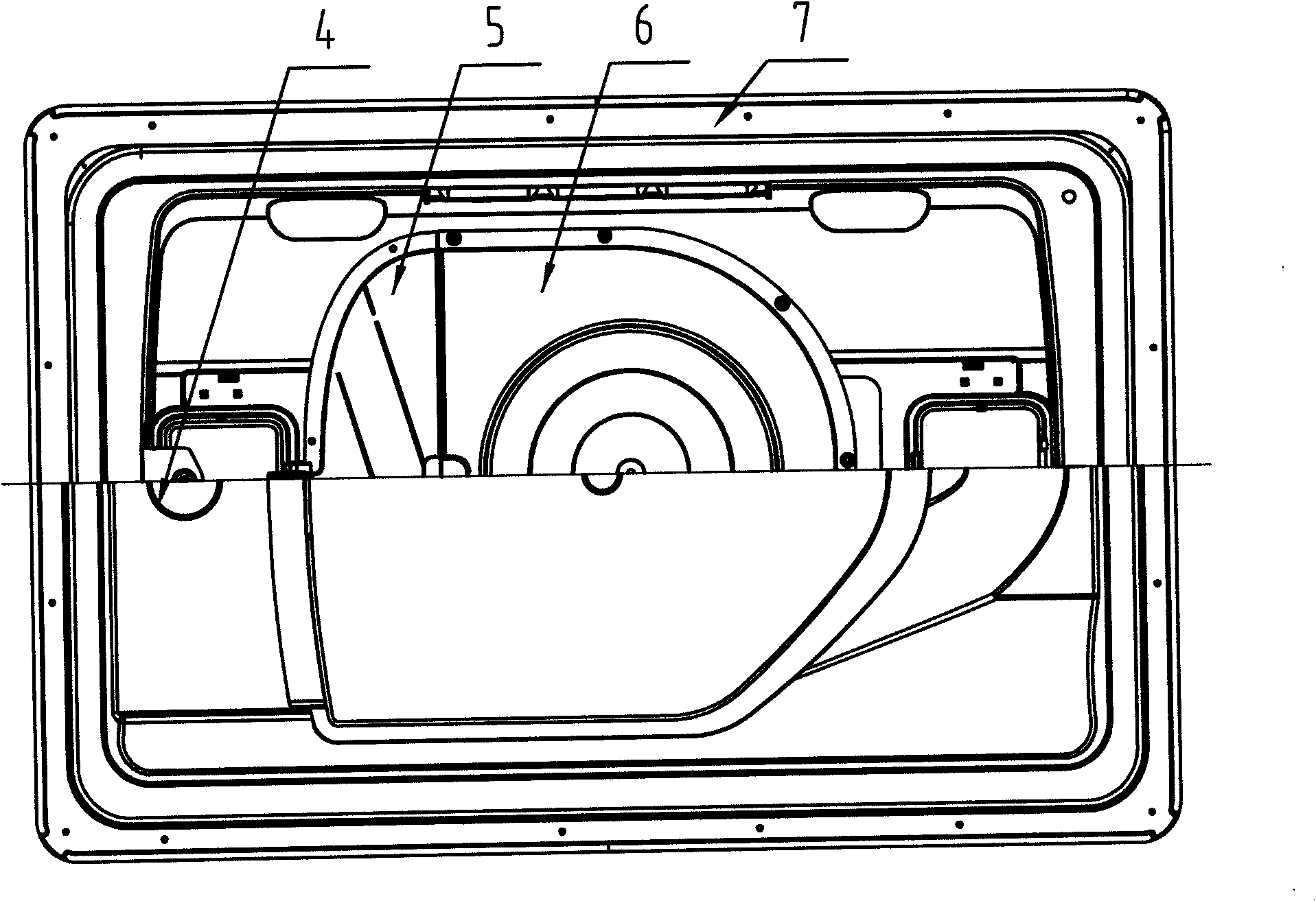

[0024] Depend on figure 2 As we know, in the rear view of this embodiment, the main frame part 9 is arranged between the sub-frame 3 and the rain cover 5, the motor is fixed in the middle of the wind guide ring 8, the sub-frame 3, the inner cover 1 and the decorative cover 2 are placed on the top. Cover the inner ring of 4.

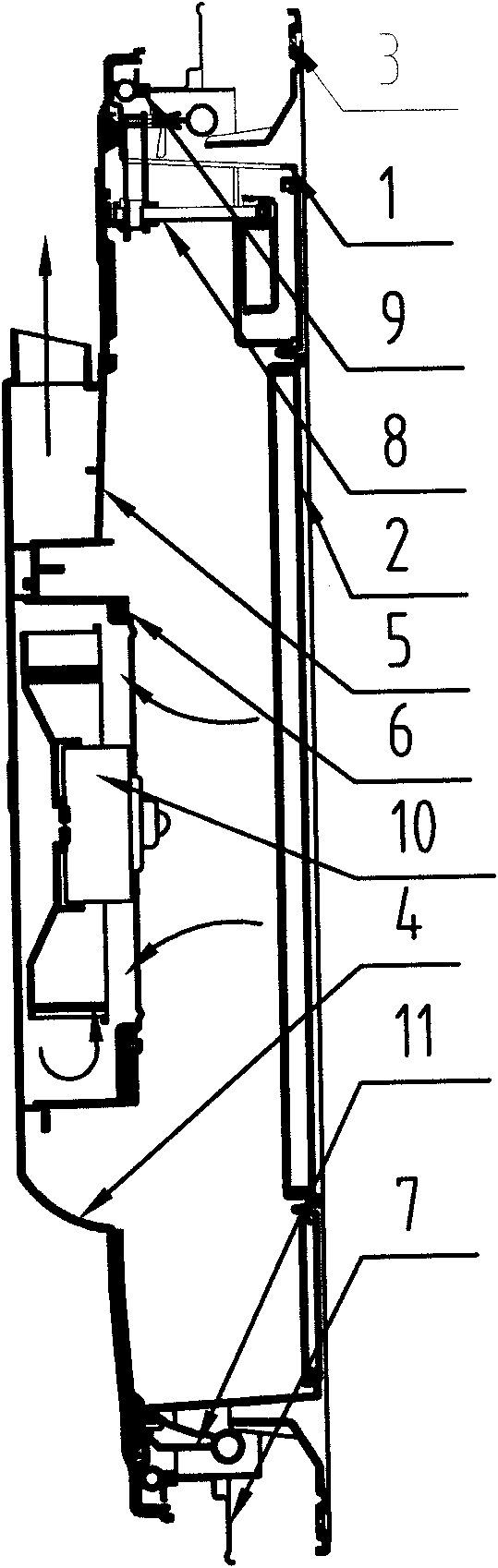

[0025] Depend on image 3 It is a schematic diagram of the structure of the rain cover 5 of the present embodiment, the push-pull device 13 and the opening device 11 are respectively fixed on the front and rear ends of the top cover 4, the rain cover 5 is fixed inside the top cover 4, and a main Frame part 9, and is fixed on the top cover 4, and the vertical direction of main frame part 9 has a straight side, and special-shaped rubber sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com