Pump body assembly, heat exchange equipment, fluid machine and operation method of fluid machine

A technology of fluid machinery and components, applied in the direction of liquid variable displacement machinery, pump components, mechanical equipment, etc., can solve the problems of large exhaust resistance, reduced effective exhaust area, and increased exhaust pressure, so as to improve overcompression , the effect of increasing the exhaust area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

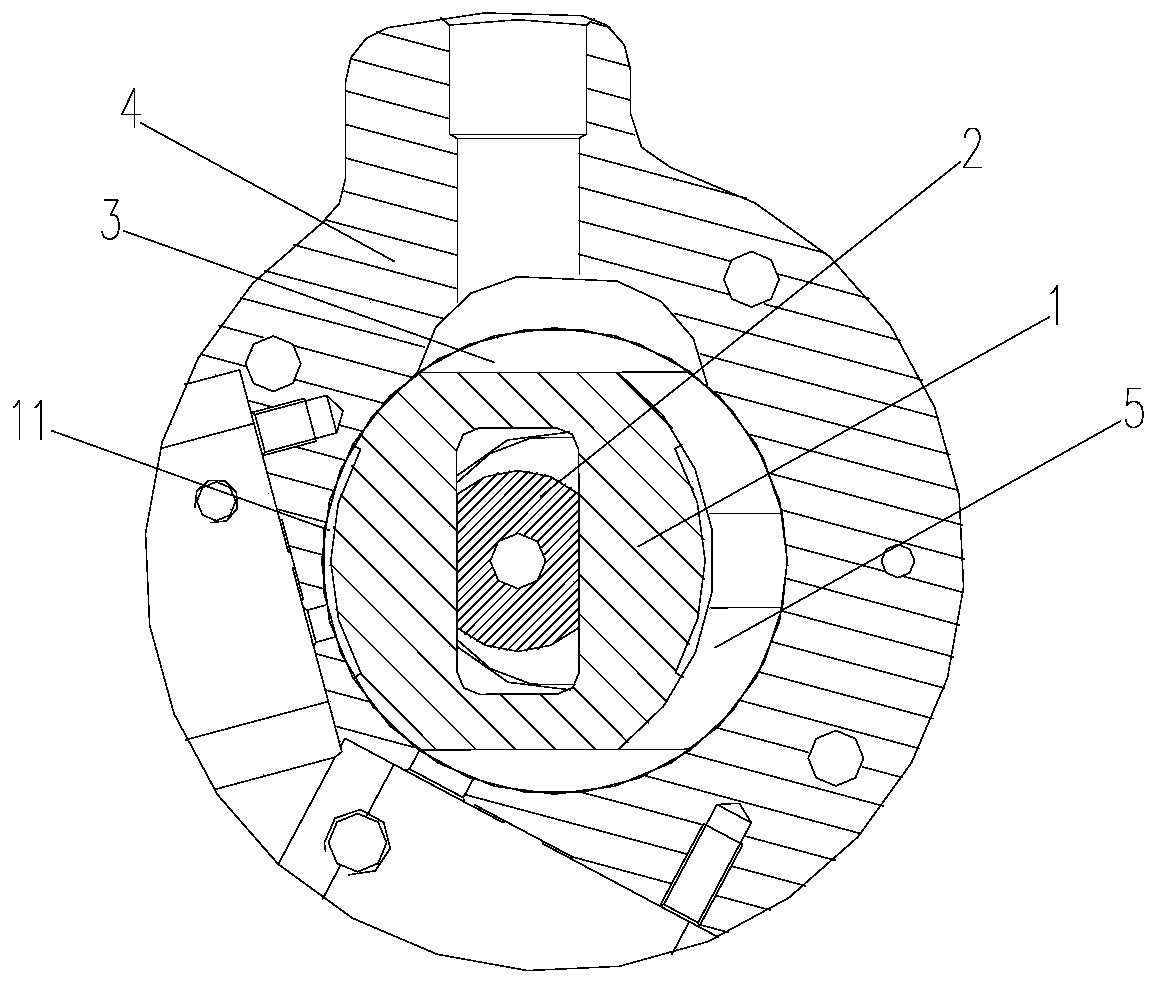

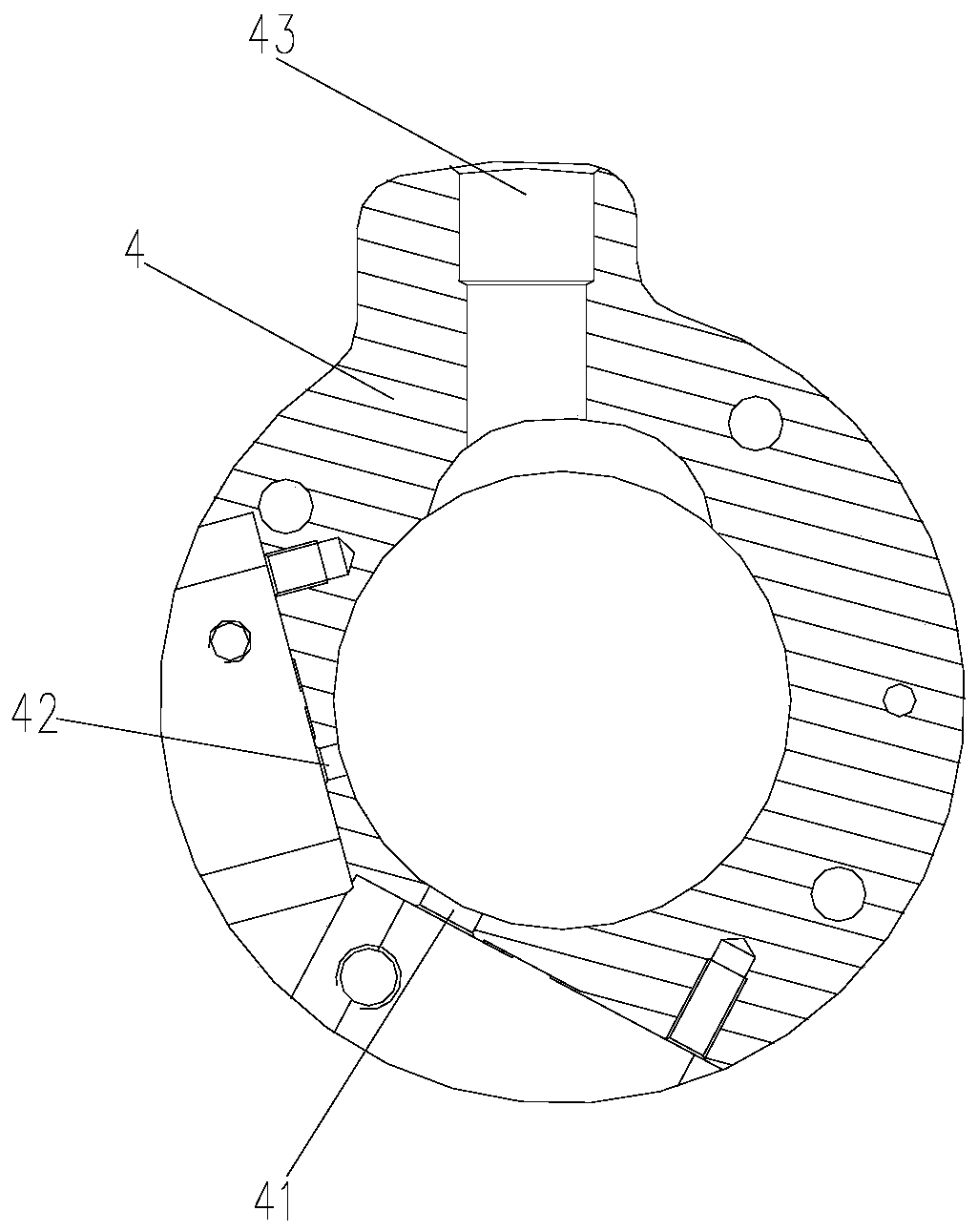

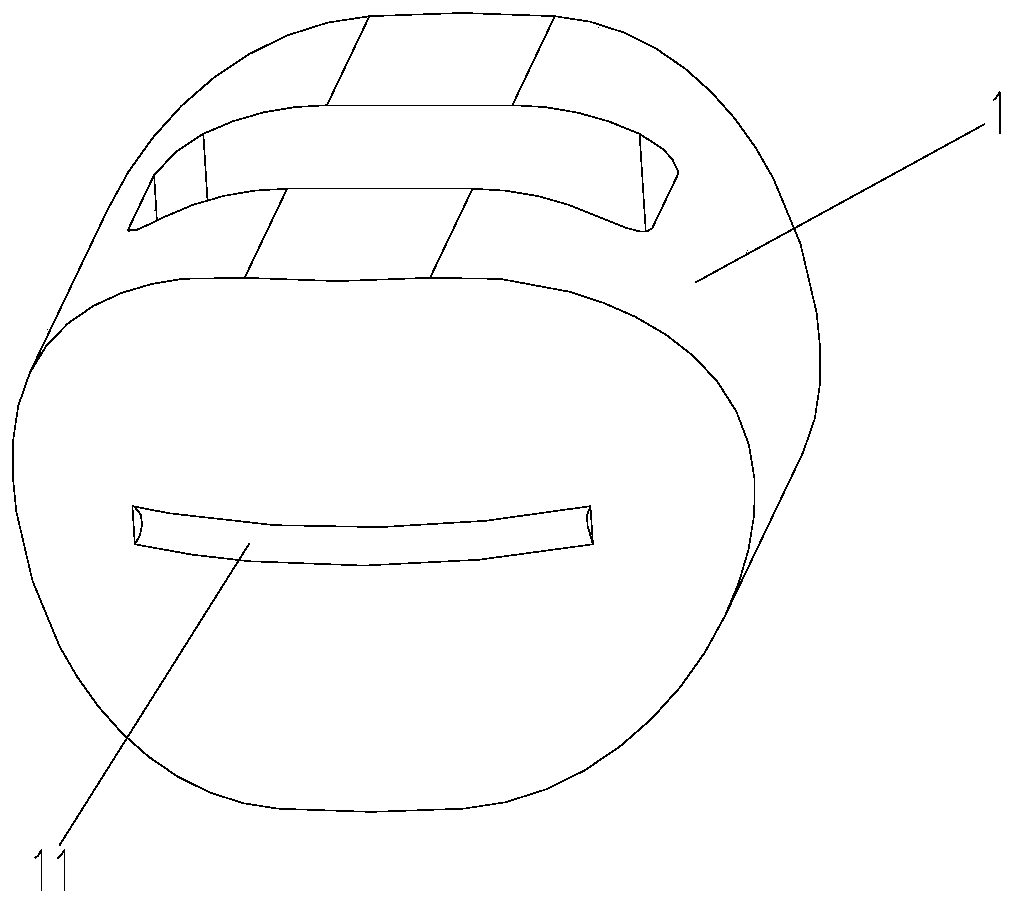

[0049] Such as Figure 1 to Figure 9 As shown, the pump body assembly includes a piston 1, a rotating shaft 2, a piston sleeve 3, and a cylinder 4. The rotating shaft 2 drives the piston 1 to reciprocate in the piston sleeve 3 while rotating; the cylinder, the piston sleeve 3 are located in the cylinder 4, and the piston 1 A compression chamber 5 is formed between the outer peripheral wall of the piston 1 and the inner wall of the cylinder 4 , and a pressure relief recess 11 is provided on the outer peripheral wall of the piston 1 or the inner wall of the cylinder, and the pressure relief recess 11 corresponds to the compression chamber 5 .

[0050] It should be noted that, in this embodiment, the pressure relief recess 11 is opened on the outer peripheral wall of the piston 1 .

[0051] Applying the technical scheme of the present invention, the piston sleeve 3 is located in the cylinder, and a compression chamber 5 is formed between the outer peripheral wall of the piston 1 an...

Embodiment 2

[0083] The main difference between this embodiment and the first embodiment is that the pressure relief recess 11 is provided on the cylinder 4 .

[0084] Specifically, the pump body assembly includes a piston 1, a rotating shaft 2, a piston sleeve 3, and a cylinder 4. The rotating shaft 2 drives the piston 1 to reciprocate in the piston sleeve 3 while rotating. The cylinder, the piston sleeve 3 is located in the cylinder 4, and the compression chamber 5 is formed between the outer peripheral wall of the piston 1 and the inner wall of the cylinder 4, and the inner wall of the cylinder 4 is provided with a pressure relief recess 11, and the pressure relief recess 11 corresponds to the compression chamber 5 .

[0085] Applying the technical solution of the present invention, the piston sleeve 3 is located in the cylinder, and a compression chamber 5 is formed between the outer peripheral wall of the piston 1 and the inner wall of the cylinder, and a pressure relief recess 11 is ...

Embodiment 3

[0088] The main difference between this embodiment and Embodiment 1 is that, as Figure 10 and Figure 11 As shown, the cross-section of the pressure relief groove is a rectangle, which is more convenient to process than a semicircle, and only needs to move the cutter head in one direction during the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com