Novel anti-overflow pot cover

An anti-overflow and pot cover technology, applied in the direction of preventing overflow, cooking utensil lids, etc., can solve the problems of waste, easy to dirty pot heating device, soup overflow, etc., and achieve the effect of increasing the exhaust area and improving the anti-overflow effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

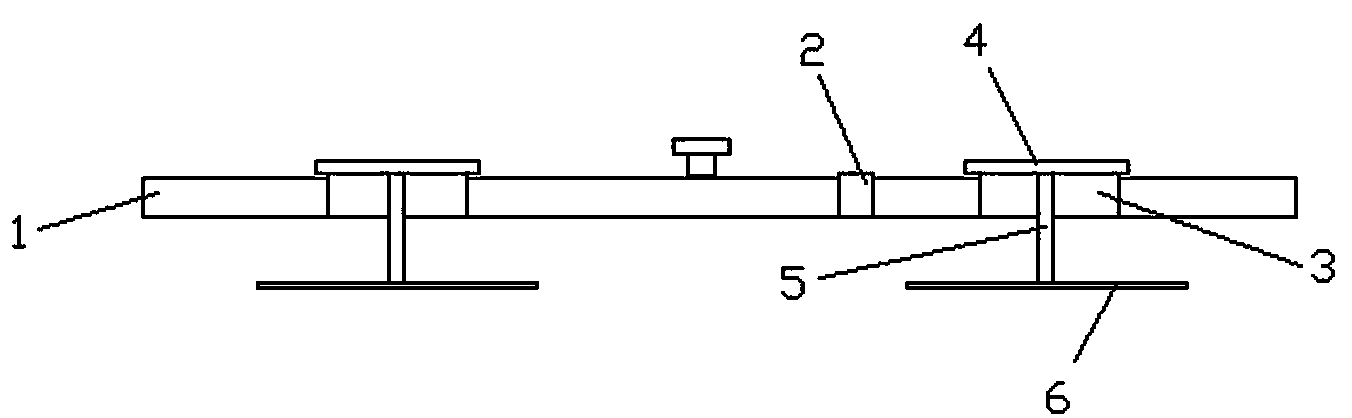

[0011] Refer to attached figure 1 as follows:

[0012] A new type of anti-overflow pot cover, including a pot cover body 1, an air vent 2, a spare hole 3, a sealing cover 4, a connecting rod 5 and a hard foam sheet 6, which is characterized in that the pot cover body 1 is provided with a diameter of 1 cm The two ends of the pot cover body 1 are equipped with a spare hole 3 with a diameter of 4 cm. The spare hole 3 is sealed by a sealing cover 4, and the sealing cover 4 is connected with a hard foam sheet 6 through a connecting rod 5. The hard foam sheet 6 is a cylinder with a diameter of 8 cm and a height of 0.2 cm, which has good buoyancy. When it is heated normally, the steam in the pot is discharged through the vent hole 2 of the pot cover body 1. When the soup in the pot needs to When it overflows, it will first arrive at the position of the hard foam sheet 6, and when the position of the soup continues to rise, it will rise together with the hard foam sheet 6, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com