Passive trigger gas fire-extinguishing device for electric power machine room

A technology of fire extinguishing device and machine room, which is applied in fire rescue and other directions, can solve the problems of inability to automatically extinguish the fire and the fire extinguisher cannot be realized, and achieve the effect of increasing the exhaust area and the fire extinguishing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

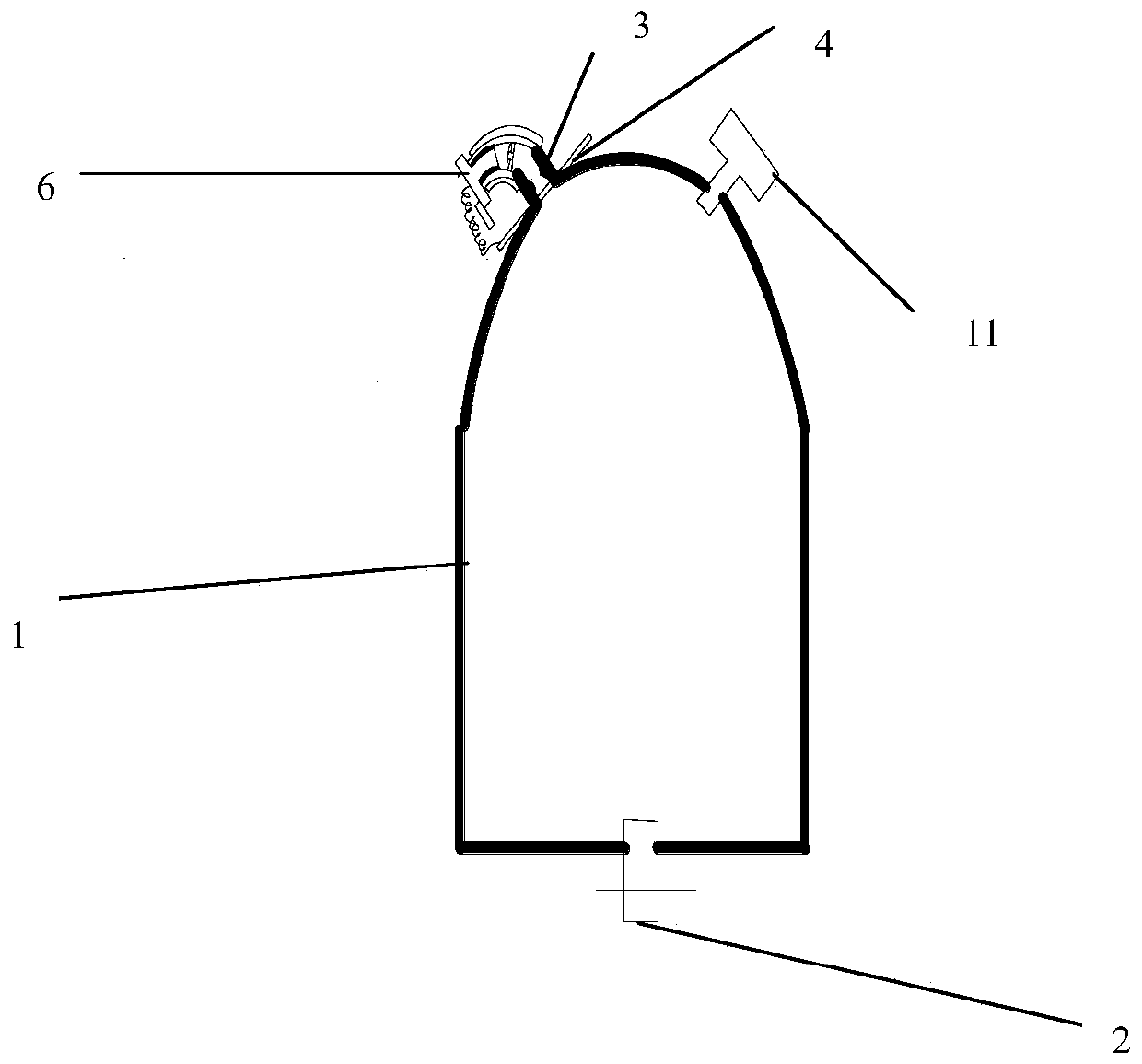

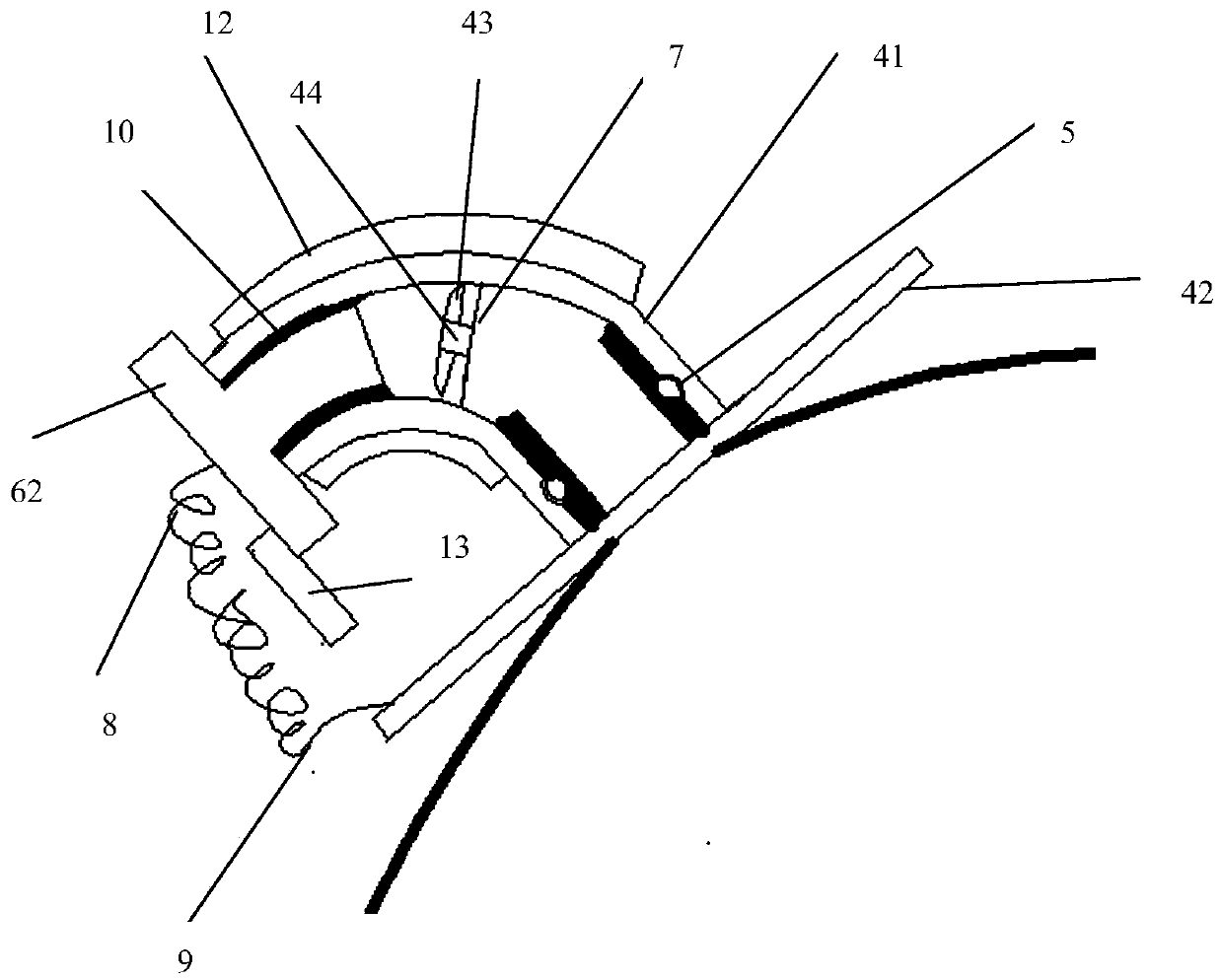

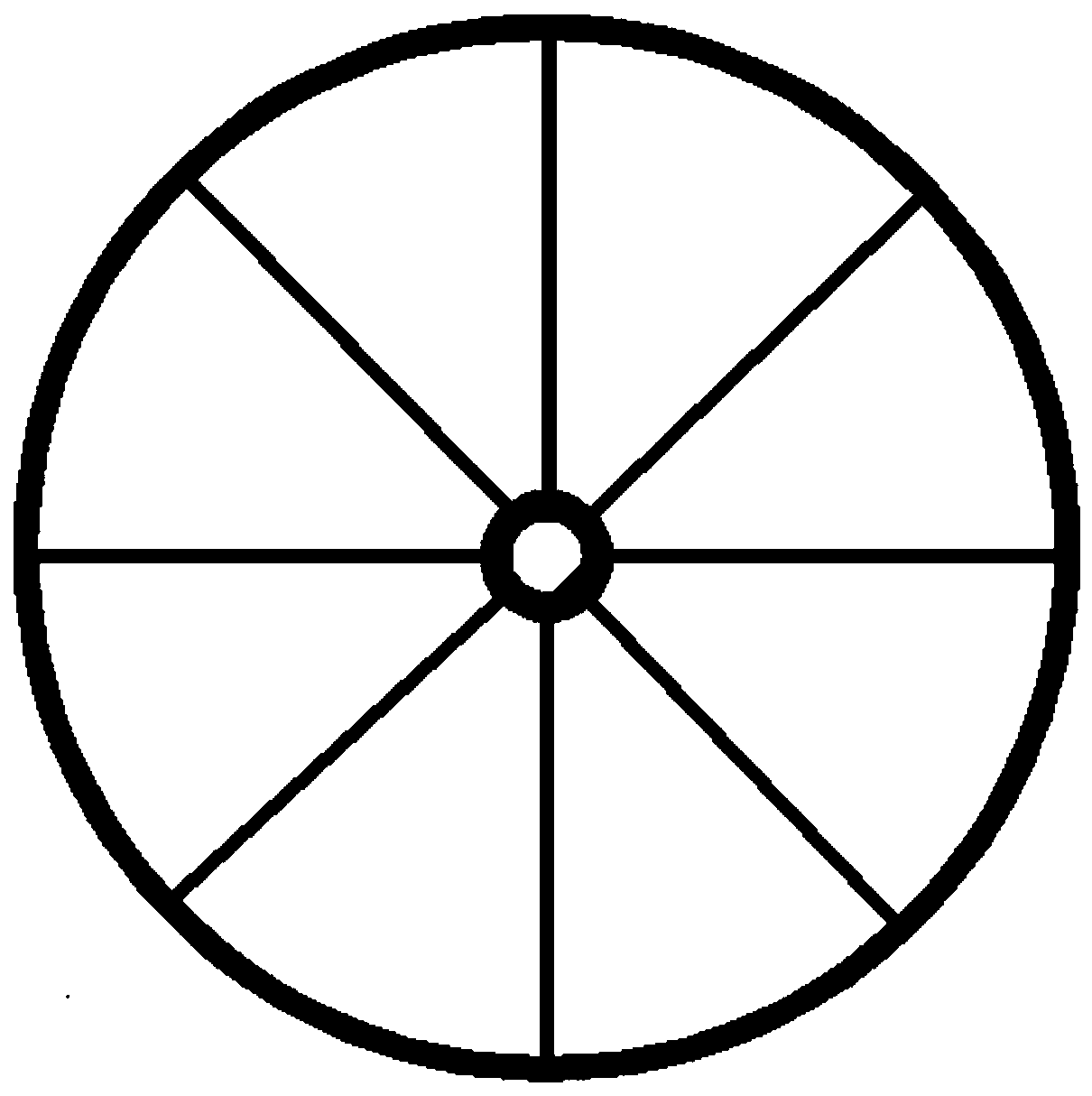

[0030] Embodiment 1, a passively triggered gas fire extinguishing device for an electric machine room, such as figure 1 , figure 2 and image 3 As shown, it includes a high-pressure gas tank 1, an intake valve 2 and an exhaust port 3. The top left side of the high-pressure gas tank 1 is provided with an exhaust port 3, and the exhaust port 3 is provided with a rotating nozzle 4, which is an elbow The rotary nozzle 4 is composed of two parts, the first part is an elbow 41, the second part is a rotary nozzle disc 42 fixedly connected with the elbow, the rotary blade 4 is provided with a rotating blade 43, and the rotating blade 43 rotates with the rotating shaft. Connect 44, the rotating shaft 44 is fixedly connected with the rotating seat 7, and the rotating seat 7 is as image 3 As shown, the rotating base 7 is fixedly connected with the rotating nozzle 4 . One end of the rotary nozzle is concentrically connected to the exhaust port of the high-pressure gas tank. A sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com