Gas exhaust device for aerostat

An exhaust device and aerostat technology, applied in the field of aerostats, can solve the problems of long closing time of the valve cover 200, affecting the accuracy of pressure difference control, affecting the precise control of airbag pressure difference, etc., so as to achieve short closing time and reduce The effect of collision and smooth discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will describe the specific implementation manners of the present invention in detail according to specific examples and with reference to the accompanying drawings. However, it should be noted that the examples described herein are only used to explain the present invention, rather than to limit the protection scope of the present invention.

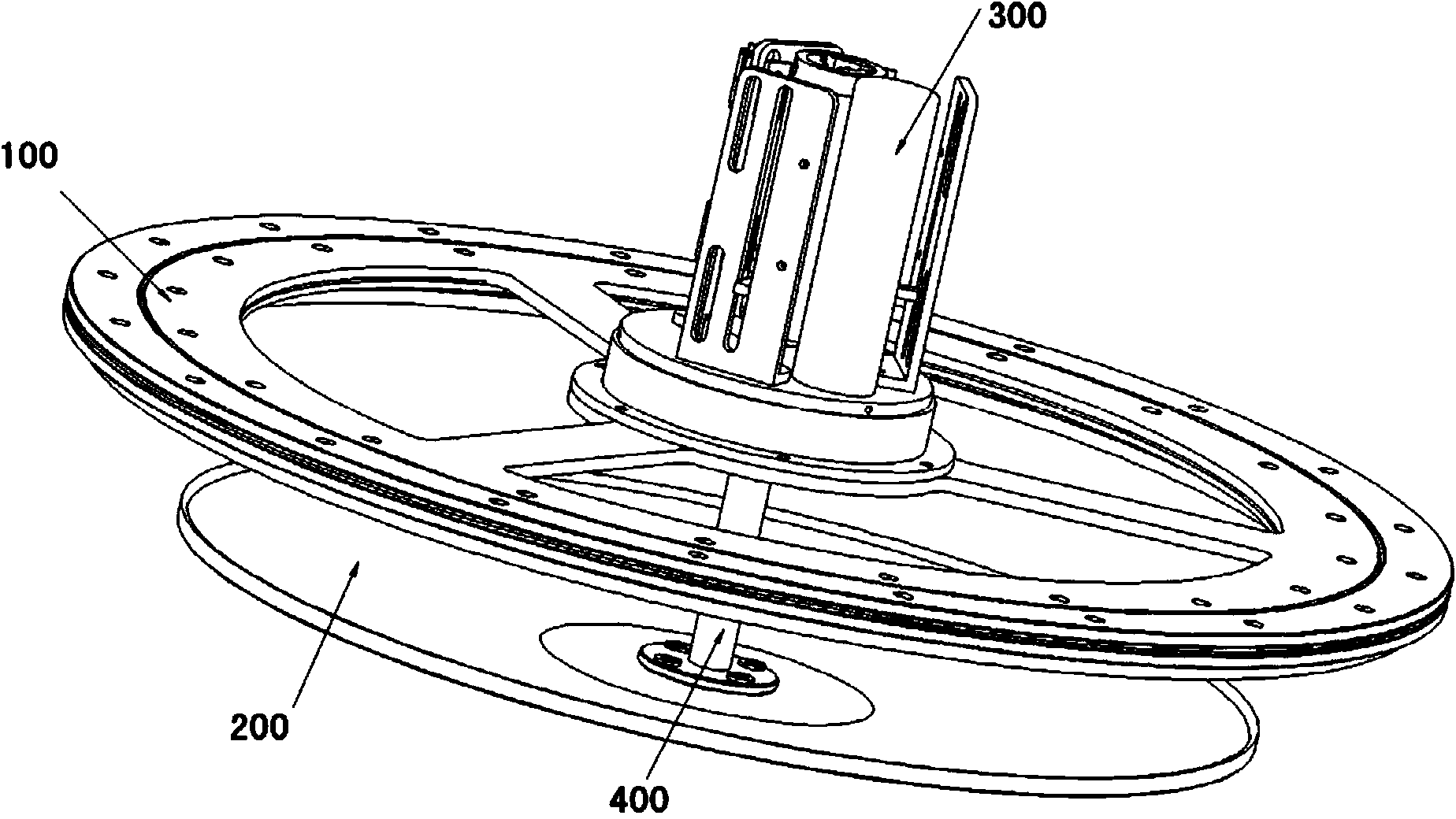

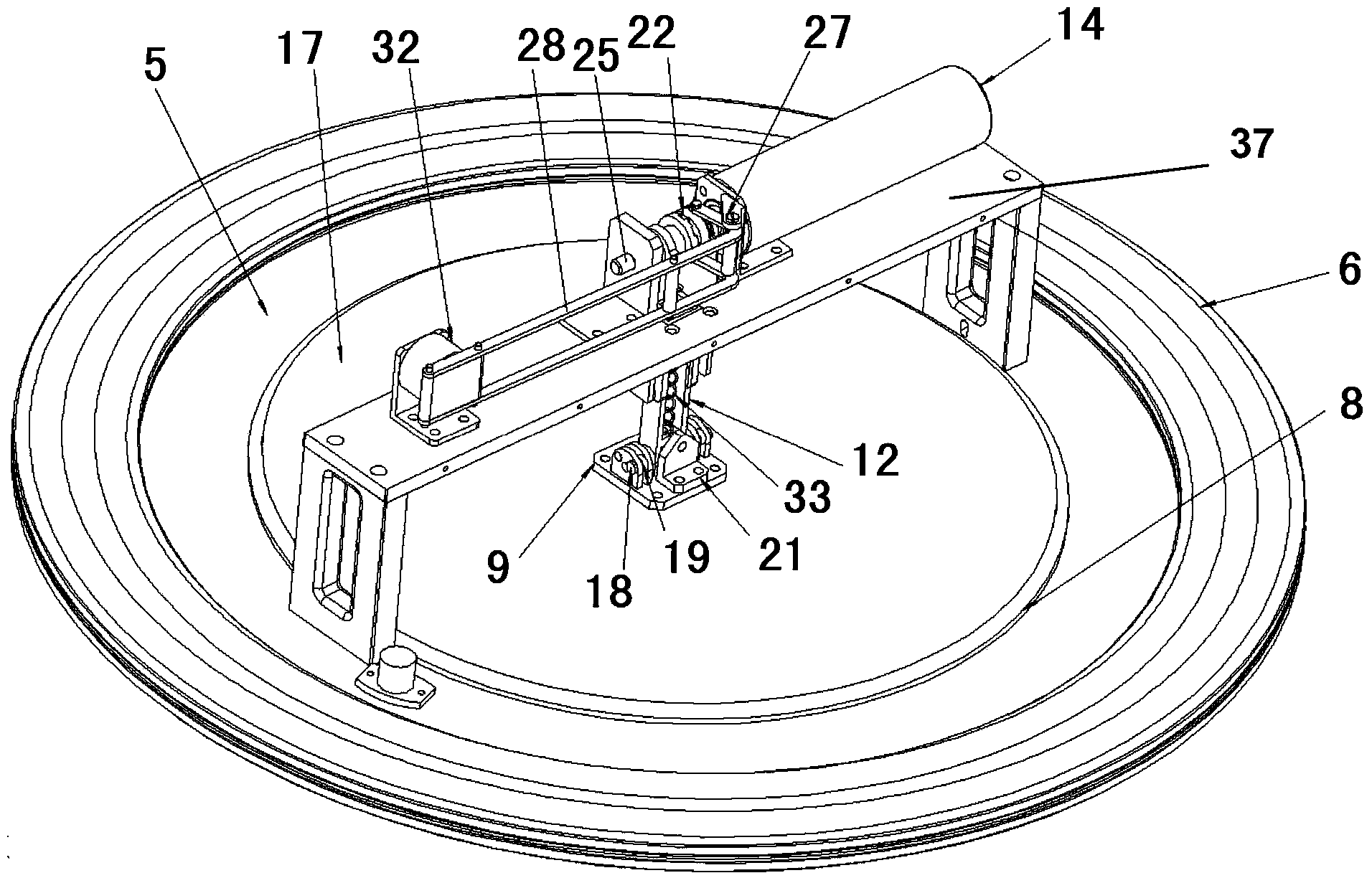

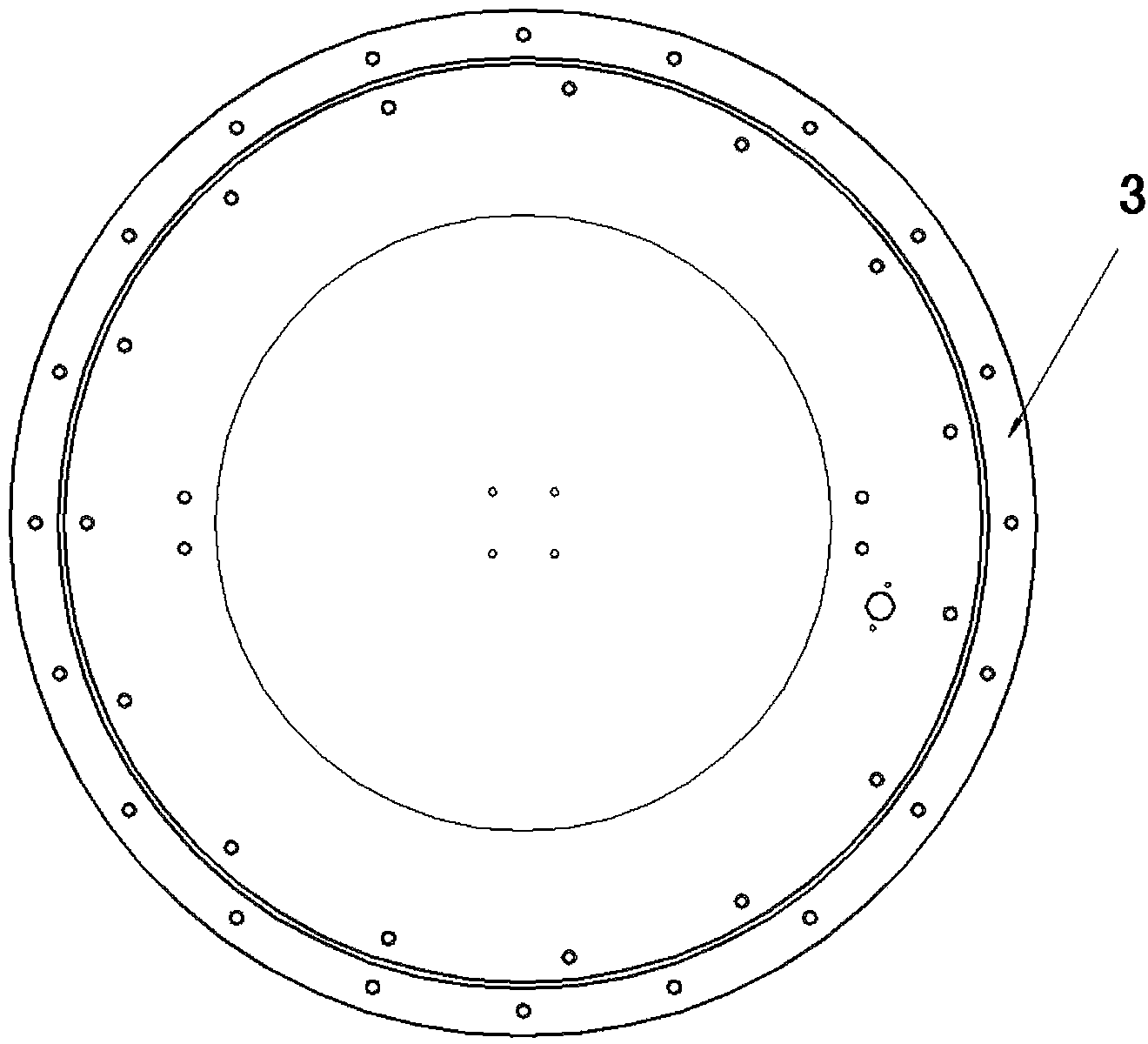

[0036] Such as figure 2 As shown, the exhaust device for an aerostat according to the present invention includes a valve including a valve body 5 and a valve cover 17 . Wherein the valve body 5 has a valve port 51, preferably the valve port 51 is a central through hole, so that the valve body has a ring shape as a whole. The valve body 5 is fixed on the suction and exhaust port of the air bag along the circumferential direction of the aerostat air bag through the valve body installation mechanism. The valve cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com