Dual-radiating structure of electric oven

A dual heat dissipation, electric oven technology, applied in the field of electric ovens, can solve problems such as poor heat dissipation effect and failure to pass the new CE certification, and achieve the effect of improving heat dissipation effect, increasing air exhaust speed, and increasing exhaust area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

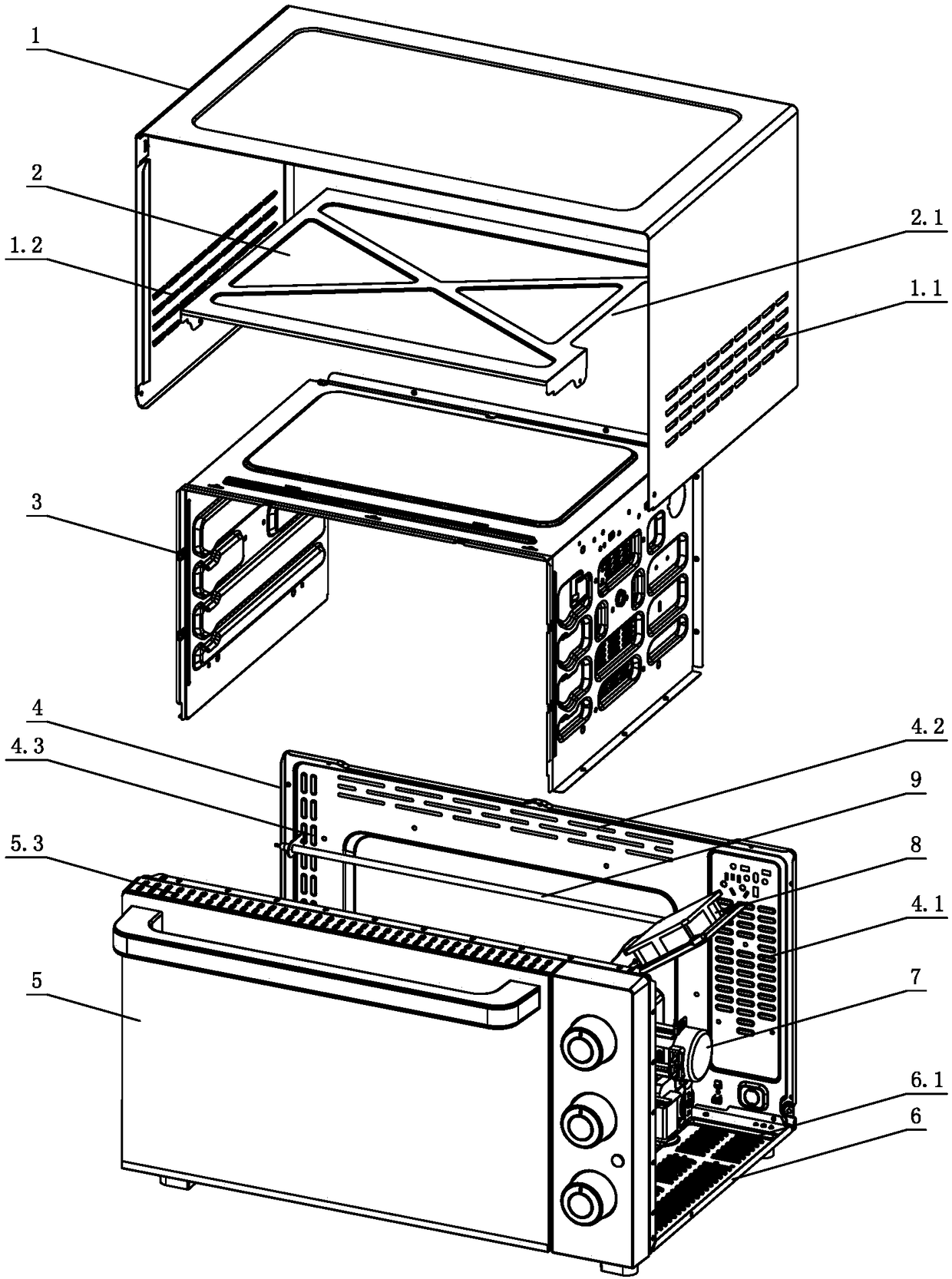

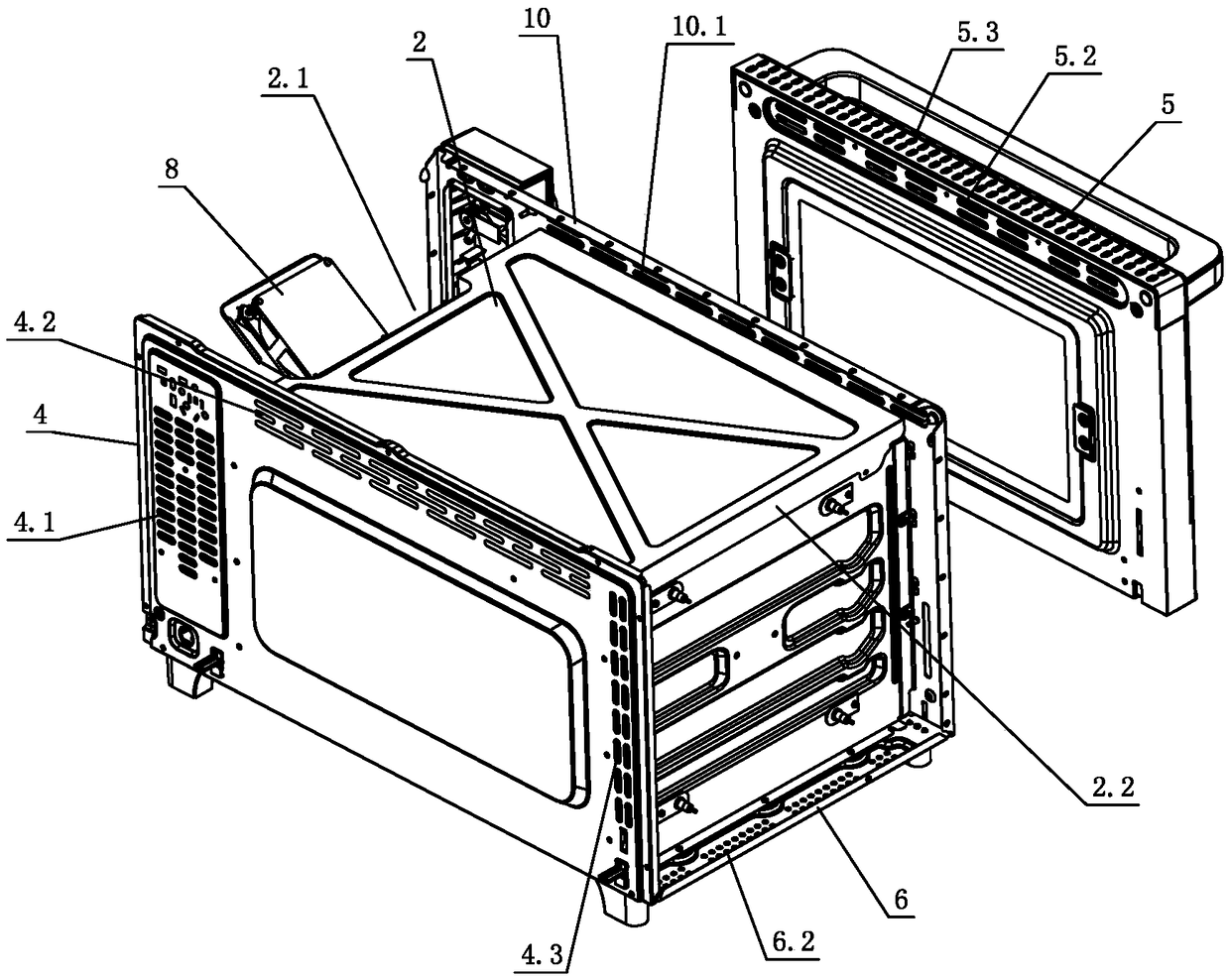

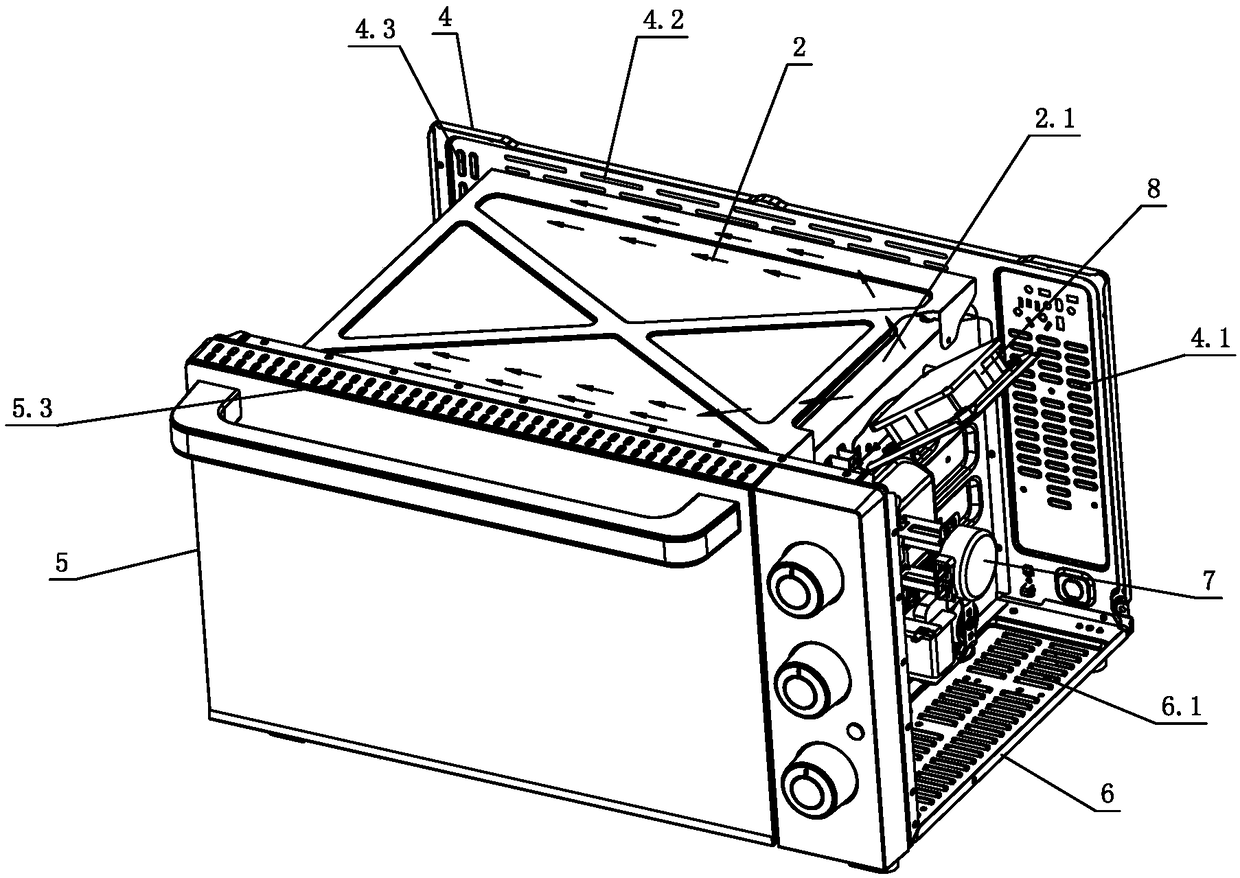

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] see Figure 1-Figure 11 , the dual heat dissipation structure of the electric oven includes an oven liner and an oven shell, and the oven shell covers the oven liner; the oven liner and the oven shell are spaced apart to form a heat dissipation gap a between them; the oven liner and the oven A heat insulation layer 2 is arranged between the shells, and the heat insulation layer 2 separates the heat dissipation gap a into a high temperature area a1 close to the oven liner and a low temperature area a2 away from the oven liner; a heat dissipation fan 8 is arranged in the heat dissipation gap a; the oven The back, side and / or bottom and / or top of the casing are provided with some ventilation holes communicating with the heat dissipation gap a, and the high temperature zone a1 and the low temperature zone a2 are respectively connected to the ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com