Single-roller opener for regenerated fibers of waste textiles

A technology for waste textiles and regenerated fibers, which is applied in fiber cleaning machines, cleaning with suction devices, etc., can solve the problems of noise pollution, no dust removal system, high maintenance costs, etc., and achieves improved uniformity and large exhaust area. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

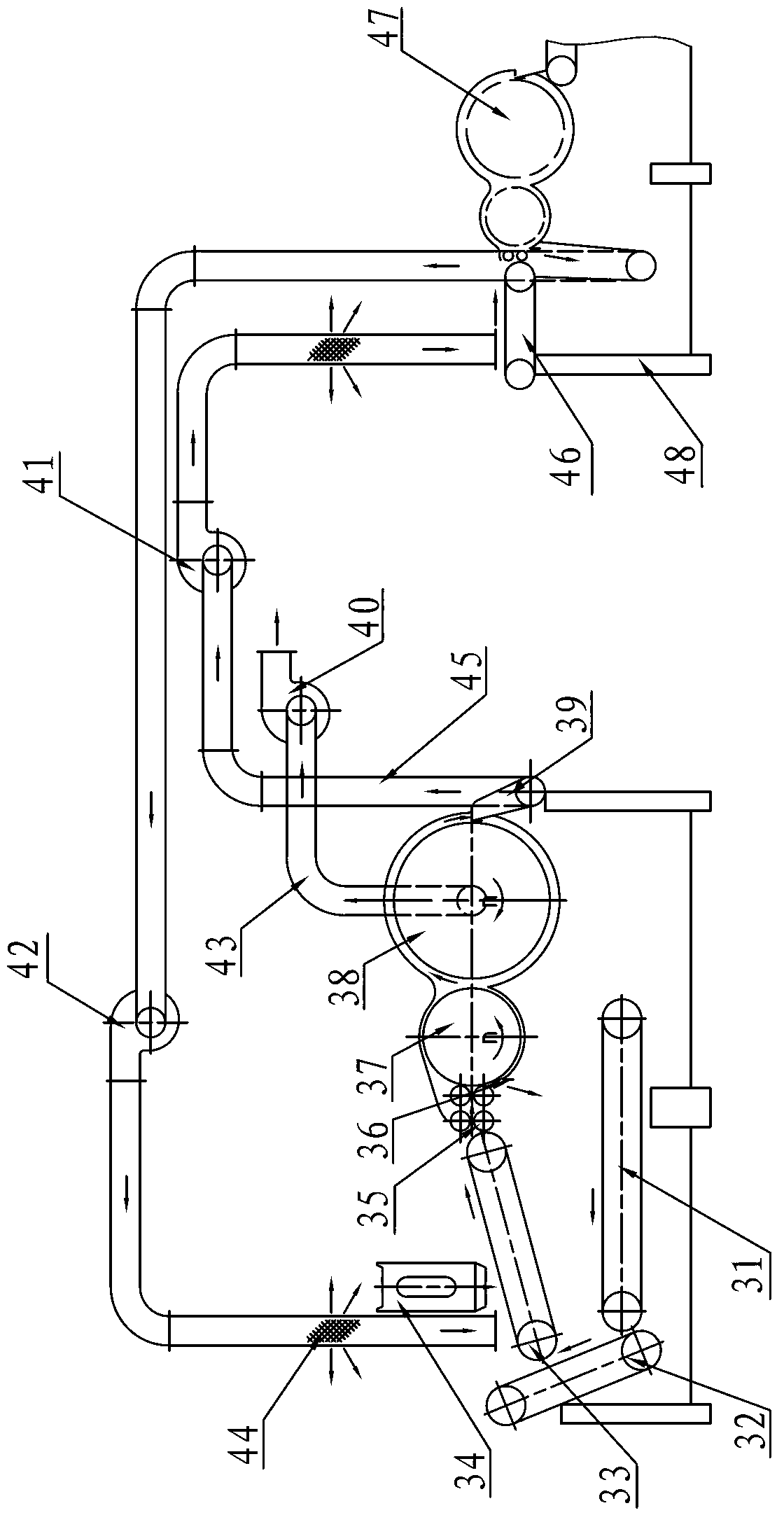

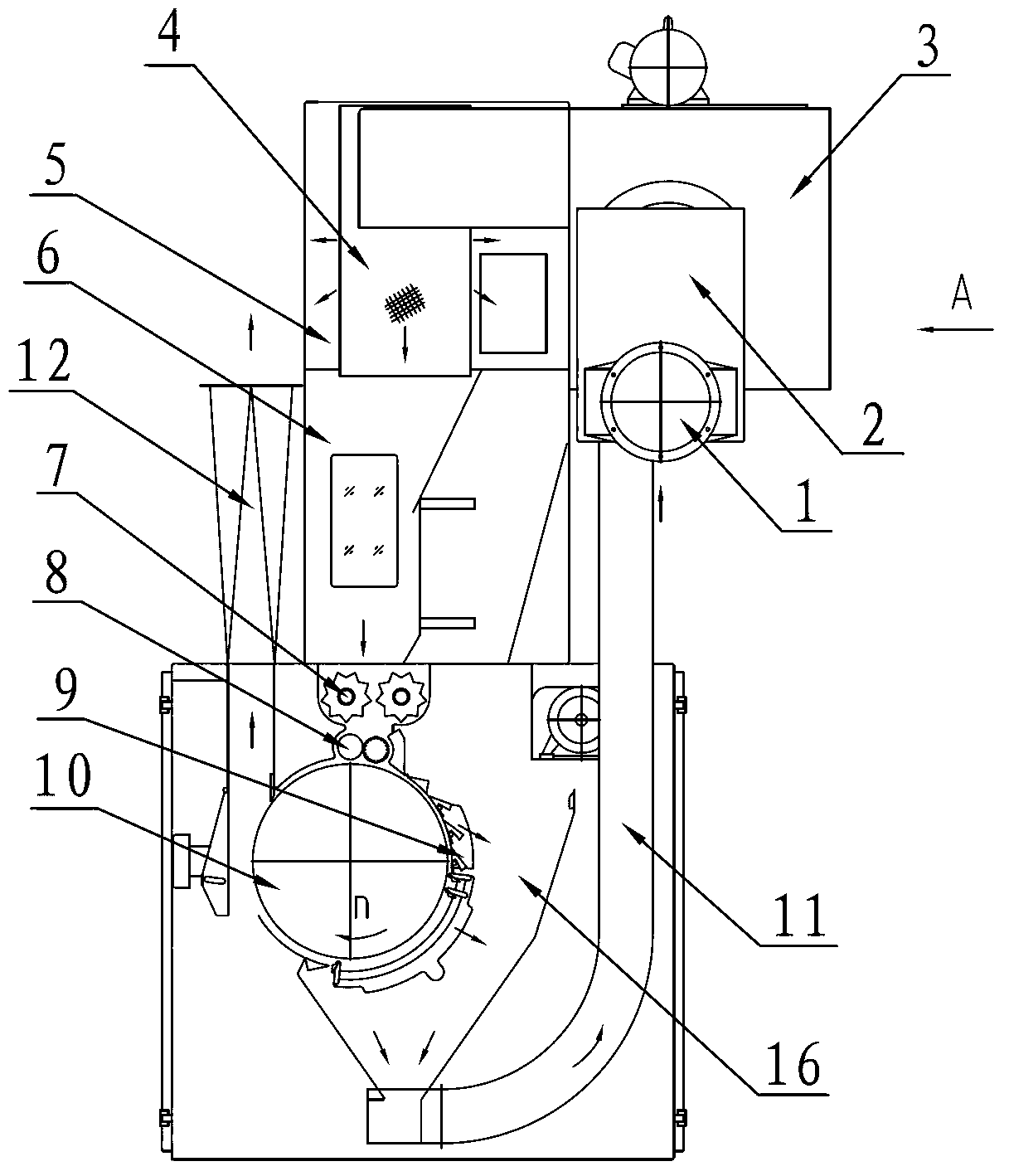

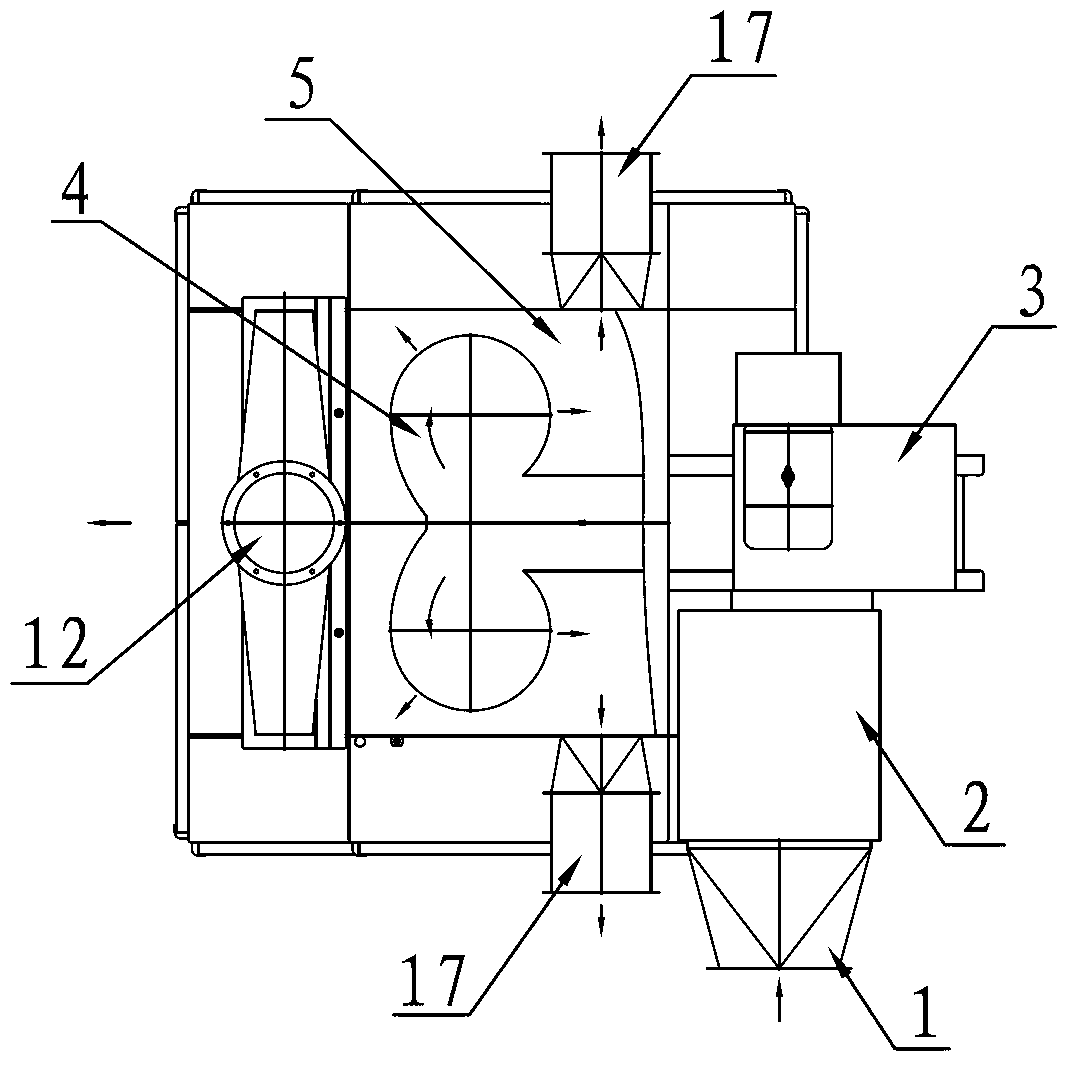

[0026] A kind of waste and old textile regenerated fiber single-roll opening machine, such as figure 2 , image 3 , Figure 4 As shown, it includes cotton inlet 1, multi-functional dust removal box 2, cotton inlet fan 3, double-round dust cage filter cartridge 4, dust velvet chamber 5, cotton storage box 6, star roller 7, front and rear steel rollers 8, Adjustable dust grid 9, opening roller 10, cotton return tube 11, cotton outlet 12, heavy dust removal rod 13, magnet 14, heavy trash box 15, cotton return hopper 16, dust filter interface 17, cotton inlet 1 It is the entrance of the multi-function dust removal box 2, the cotton suction port of the cotton inlet fan 3 is connected with the outlet of the multi-function dust removal box 2, and the cotton outlet of the cotton inlet fan 3 is connected with the inner cavity of the double-round dust cage filter cartridge 4 , the dust velvet chamber 5 is located outside the double-round dust cage filter cartridge 4, the dust velvet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com