Device for purifying pollutants in operating area

A technology of pollutants and operation area, applied in chemical instruments and methods, removal of smoke and dust, cleaning methods and utensils, etc., can solve the problems of ineffective removal of dust, damage to experimental results, influence, etc., to enhance the ability to purify pollutants, prevent Pollution, the effect of expanding the exhaust area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

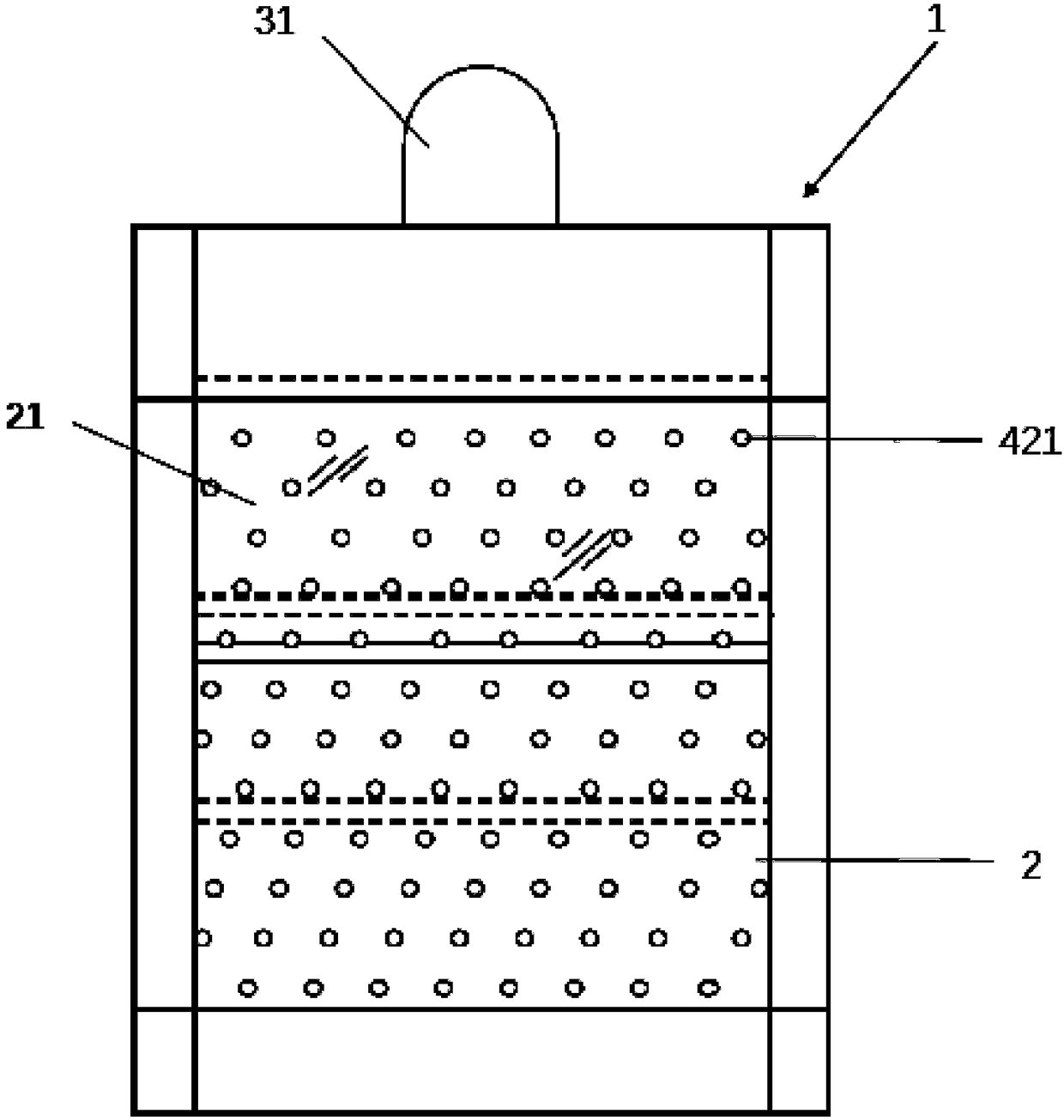

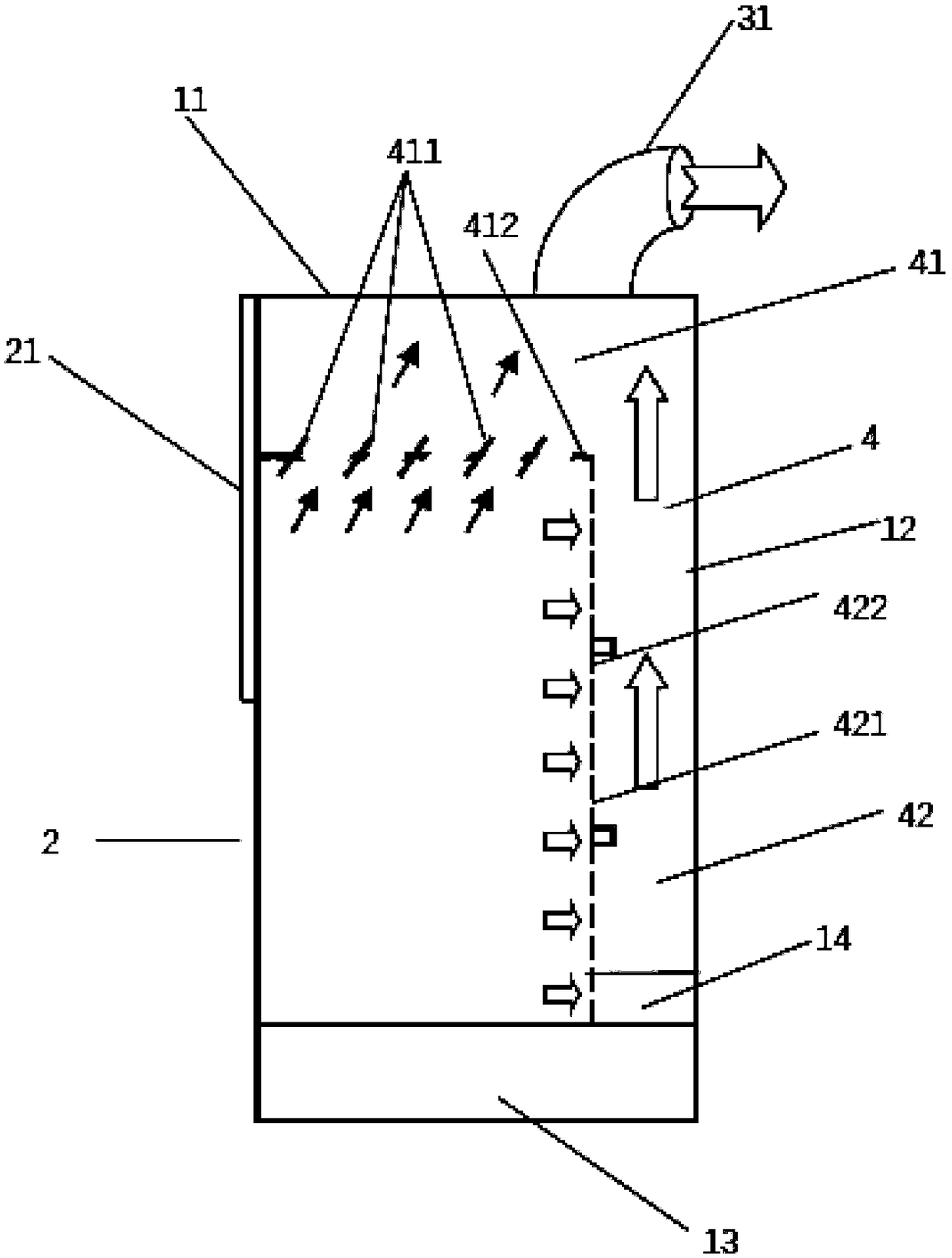

[0040] Please refer to figure 1 , figure 2 , image 3 As shown, a device for purifying pollutants in an operating area includes a main body 1, a vent 2 is provided on the front side of the main body 1, and a vent window 21 capable of controlling the opening and closing of the vent 2 is provided on the vent 2. The ventilation window 21 can be opened or closed by sliding, and the size of the ventilation opening 2 can be controlled by sliding. The sliding opening manner of the ventilation window 21 includes but not limited to horizontal sliding, vertical sliding, rotating sliding and the like.

[0041]The main body 1 is provided with a ventilation cavity 4, and the ventilation cavity 4 communicates with the ventilation interface. The ventilation cavity 4 is divided into a top ventilation cavity 41 and a vertical surface ventilation cavity 42 . The top ventilation chamber 41 is composed of a top solid wall plate 11 and a top plate 412, on which a variable-gap damper 411 is ar...

Embodiment 2

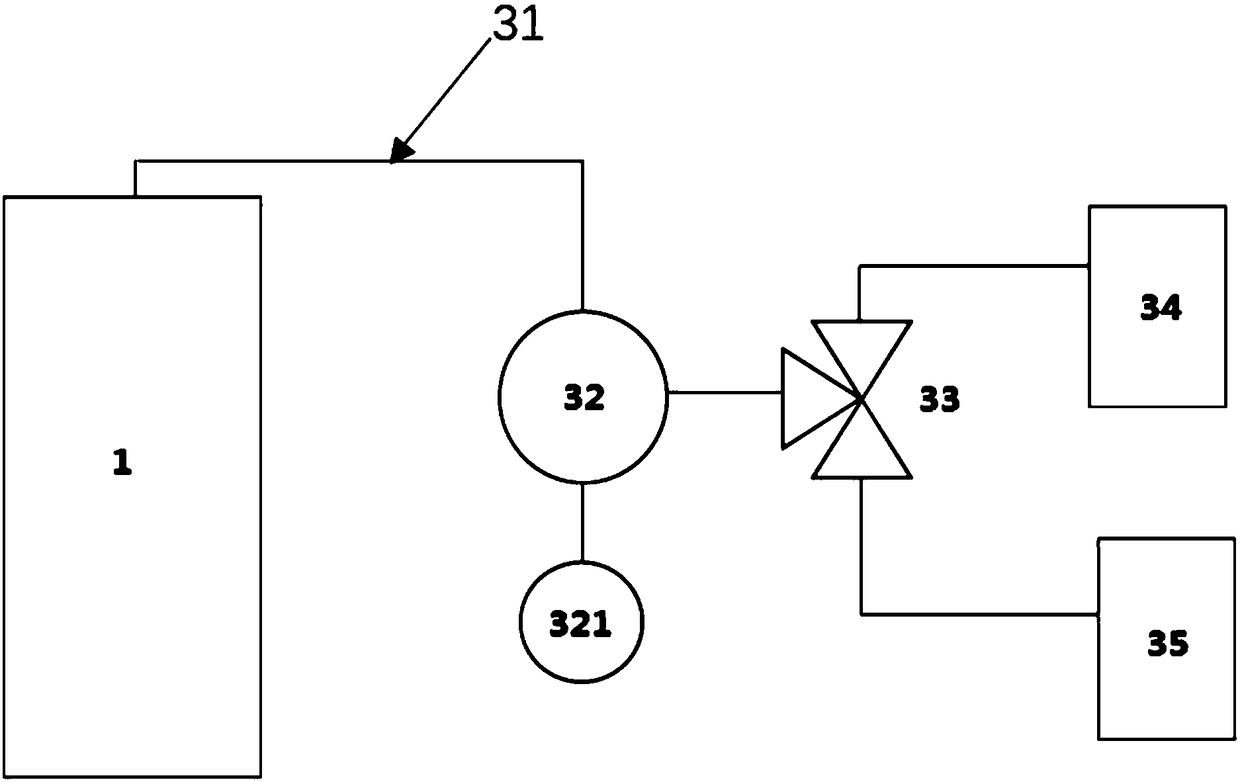

[0052] Such as Figure 4 As shown, the device for purifying pollutants in the operating area is connected in parallel by multiple devices for purifying pollutants in the operating area, sharing a set of ventilation equipment. Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com