Curved claw rotor of claw type vacuum pump and molded line design method thereof

A technology of vacuum pumps and rotors, applied in the direction of rotary piston pumps, pumps, calculations, etc., can solve problems such as wear, lower efficiency of claw vacuum pumps, and uneven meshing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

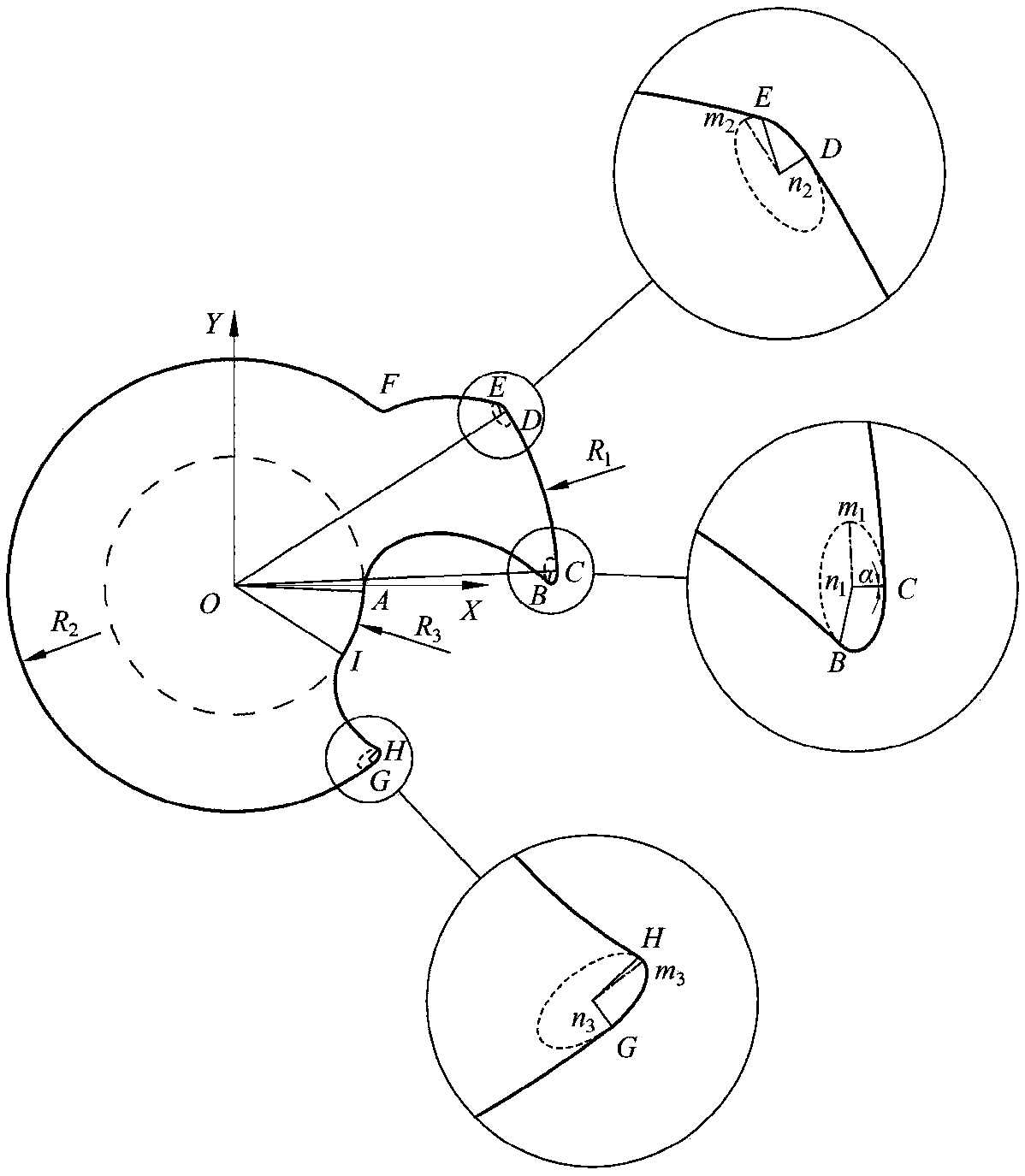

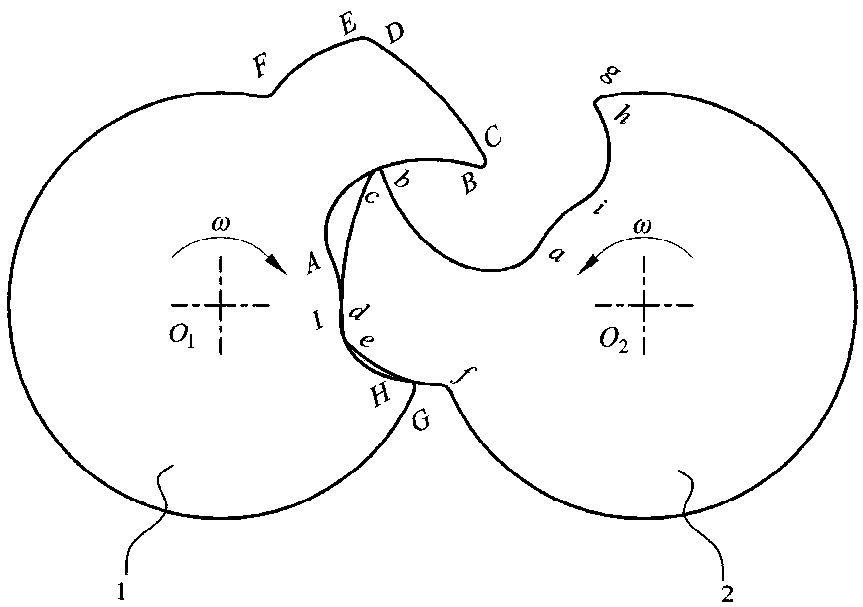

[0071] Such as figure 1 Shown is the profile diagram of the claw rotor of a proposed claw vacuum pump. According to the counterclockwise direction, the rotor profiles are: the first elliptical arc envelope line AB, the first elliptical arc BC, and the claw top circle Arc CD, second elliptical arc DE, third elliptical arc envelope EF, pitch circle arc FG, third elliptical arc GH, second elliptical arc envelope HI and claw bottom arc IA; between adjacent curves All smooth connections, no non-smooth connection points; the mechanical properties, meshing performance and sealing performance of the claw rotor are improved.

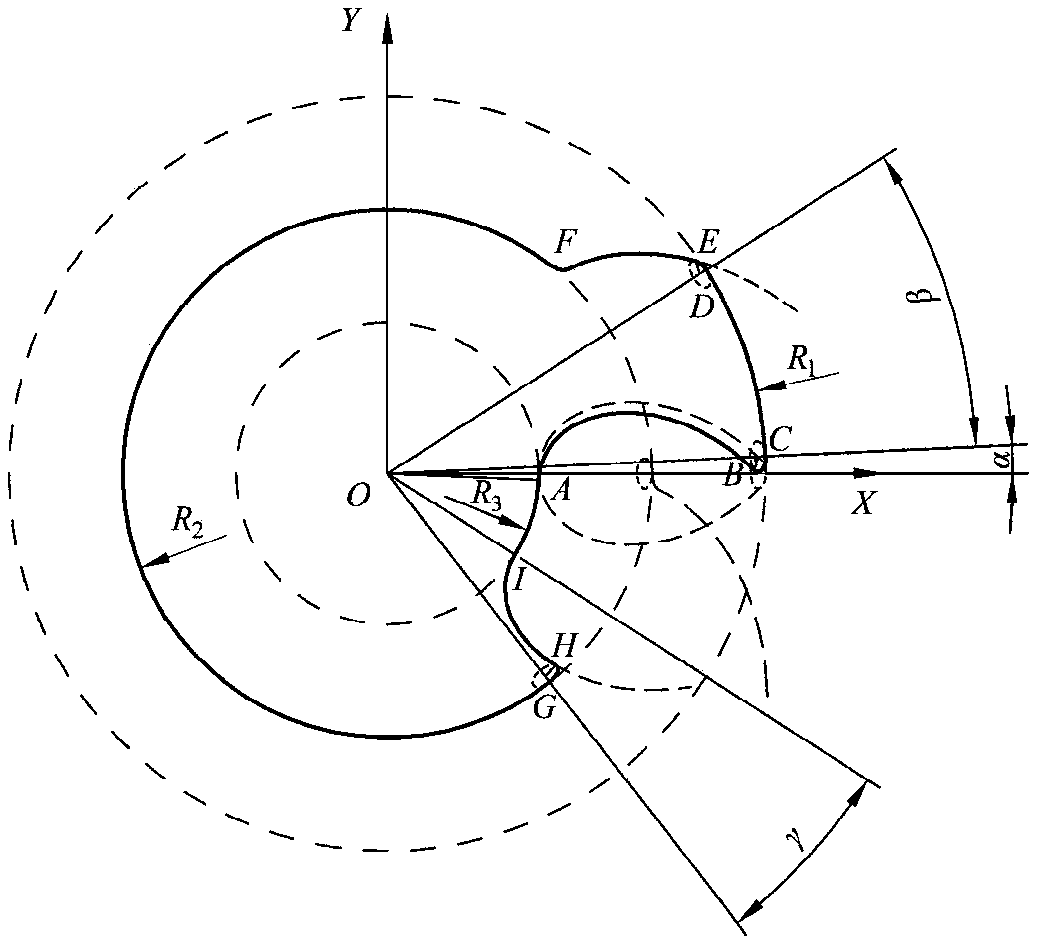

[0072] Such as figure 2 As shown, it is the profile line generation diagram of the left rotor of the claw rotor of a claw vacuum pump proposed, and the rotor profile generation method is as follows:

[0073] 1) Take the origin O as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com