Nuclear power plant fuel loading and unloading tool and loading and unloading process

A technology for loading and unloading tools and nuclear power plants, which is applied to the field of fuel loading and unloading tools and loading and unloading processes in nuclear power plants, and can solve the problems of increasing labor intensity of workers, reducing work efficiency, and cumbersome tape measure drive mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

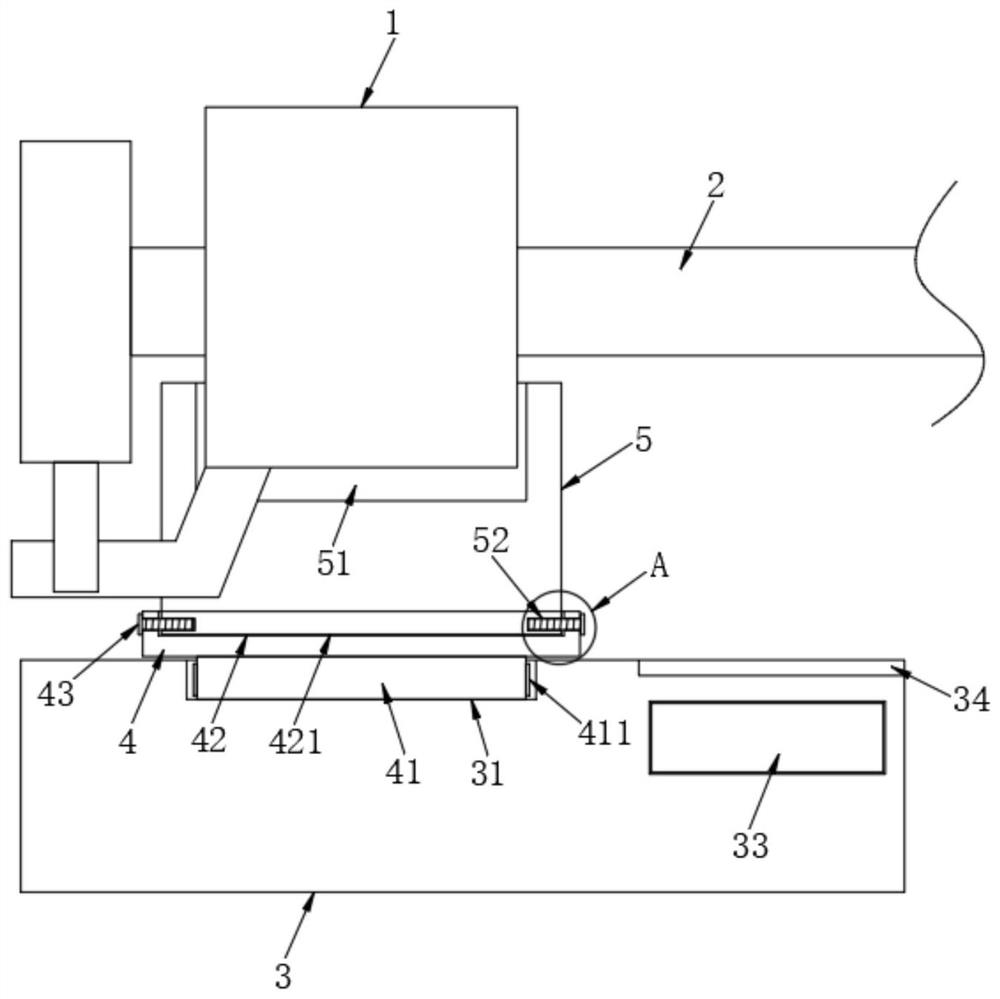

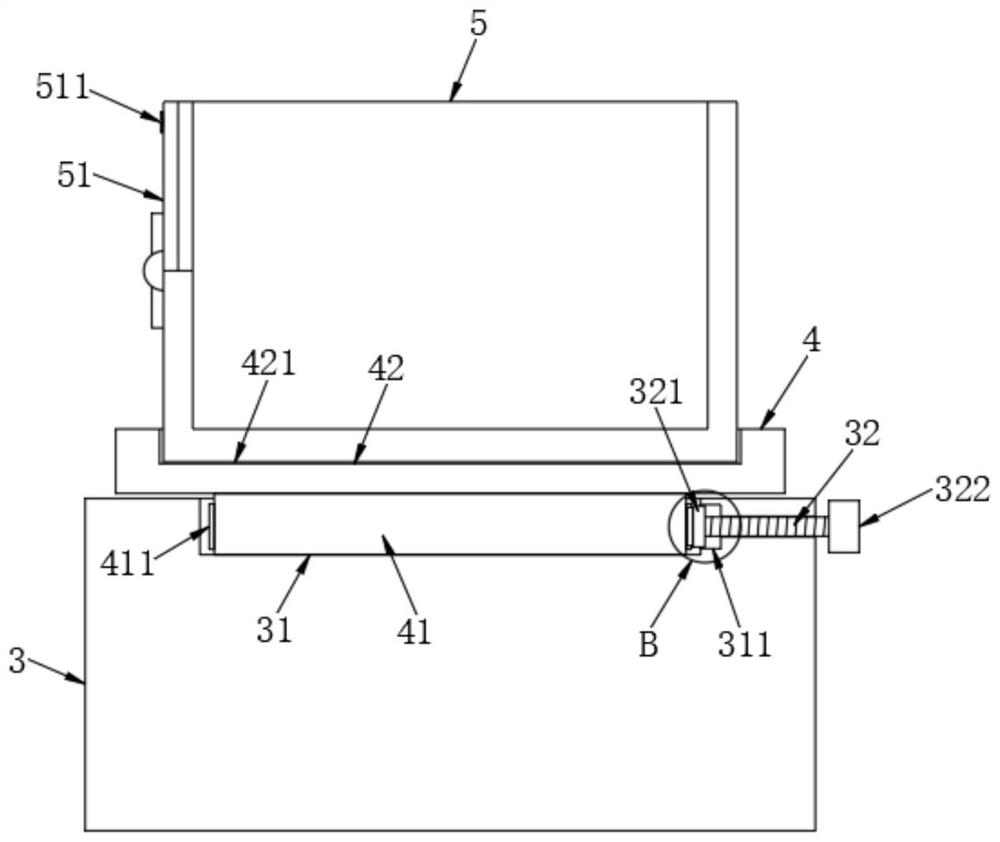

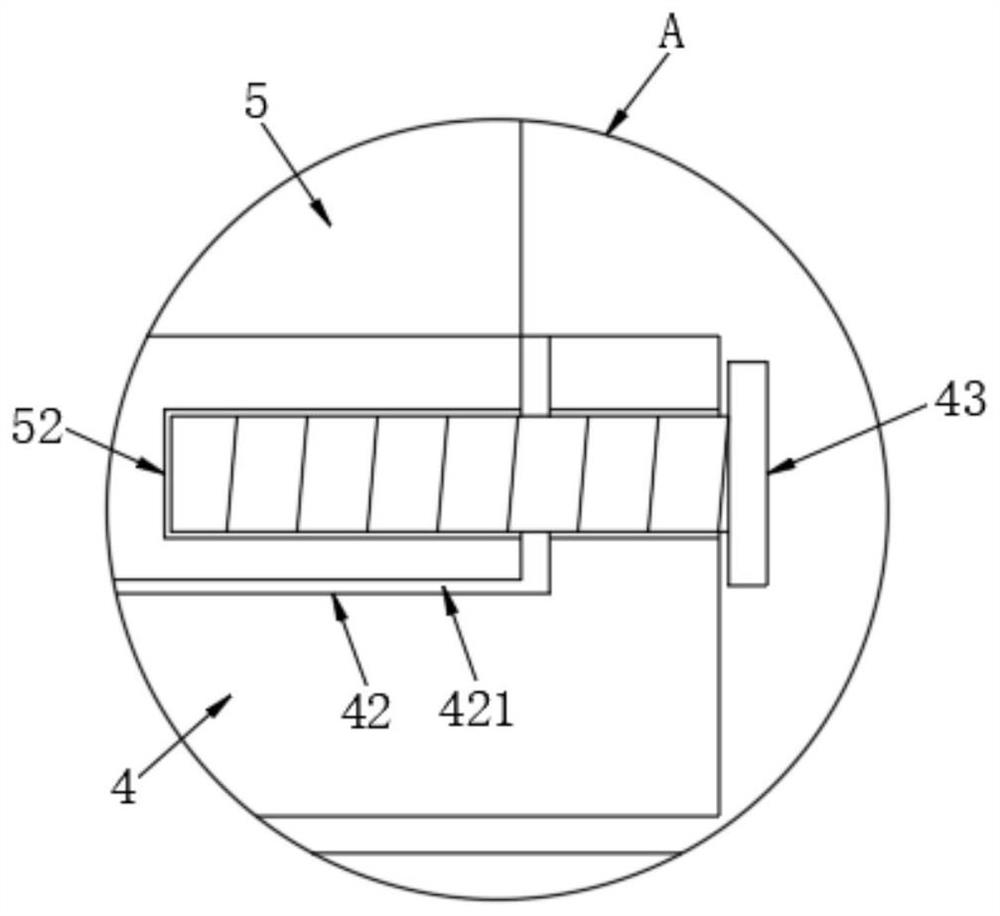

[0027] see Figure 1-5 , the present invention provides a nuclear power plant fuel loading and unloading tool: comprising a drive mechanism 1 and a push rod mechanism 2 detachably connected to the drive mechanism 1, a worktable 3 is provided under the drive mechanism 1 and the push rod mechanism 2, and the top of the workbench 3 is rotatably connected with a Turning disc 4, the top of workbench 3 is provided with turning slot 31, the bottom of turning disc 4 is fixedly connected with turning block 41, and turning block 41 is rotatably connected inside turning slot 31, and the outer wall of turning block 41 is fixedly connected with several equidistantly distributed Rack 411, screw rod 32 is threaded inside the outer wall of workbench 3, and one end of screw rod 32 located inside rotating groove 31 is connected with tooth plate 321 for rotation, tooth plate 321 is meshed with rack 411, and the top of rotating disk 4 is engaged and installed inside Mounting frame 5 is arranged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com