Compressor

A compressor and compression mechanism technology, applied in the field of compressors, can solve the problems of compressor efficiency decrease, noise and power consumption increase, etc., so as to simplify the overall structure and cost, reduce the risk of leakage to the suction side, reduce residual The effect of void volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage. The same reference numerals are used to denote the same components in the respective drawings, and thus the configurations of the same components will not be described repeatedly.

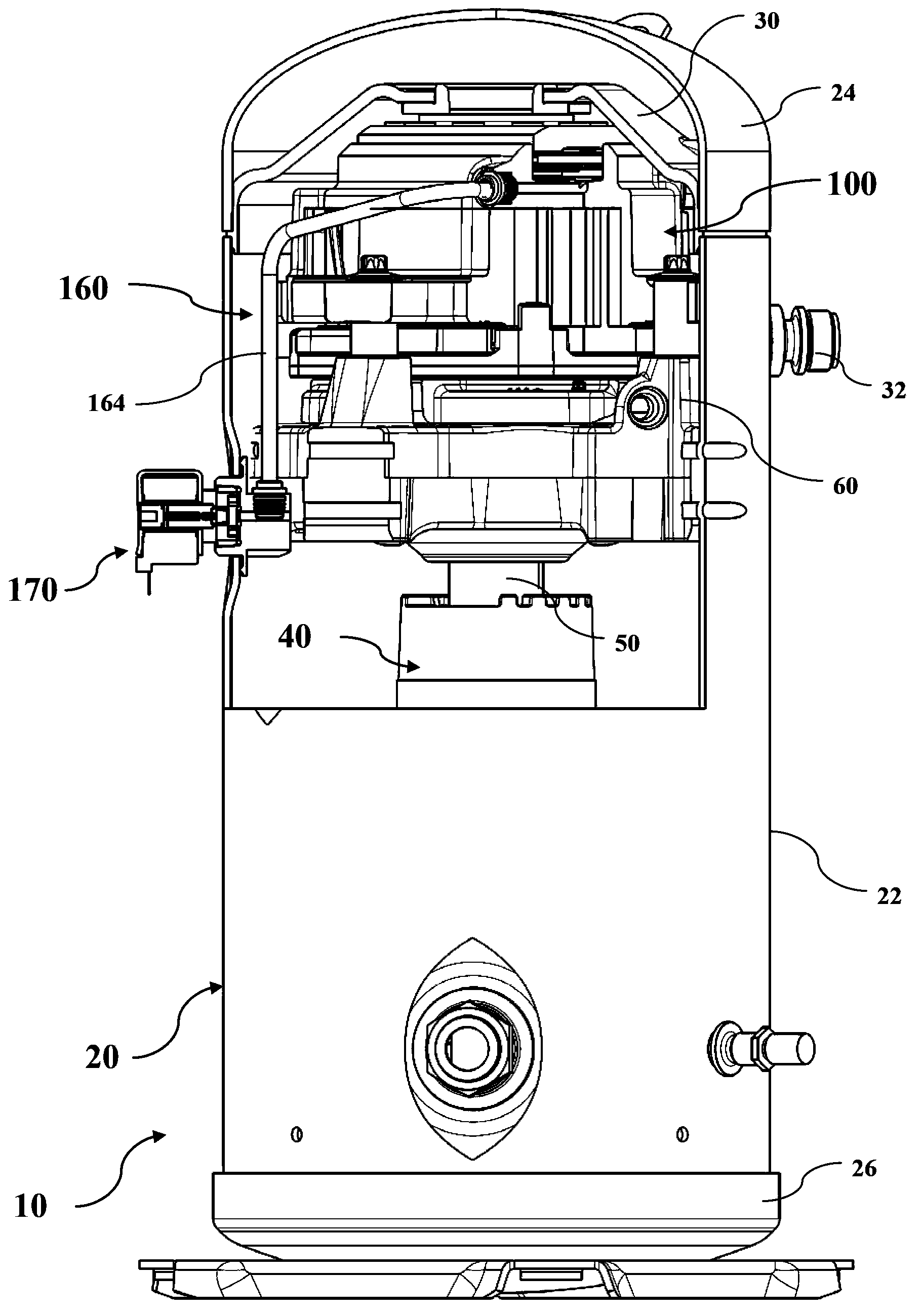

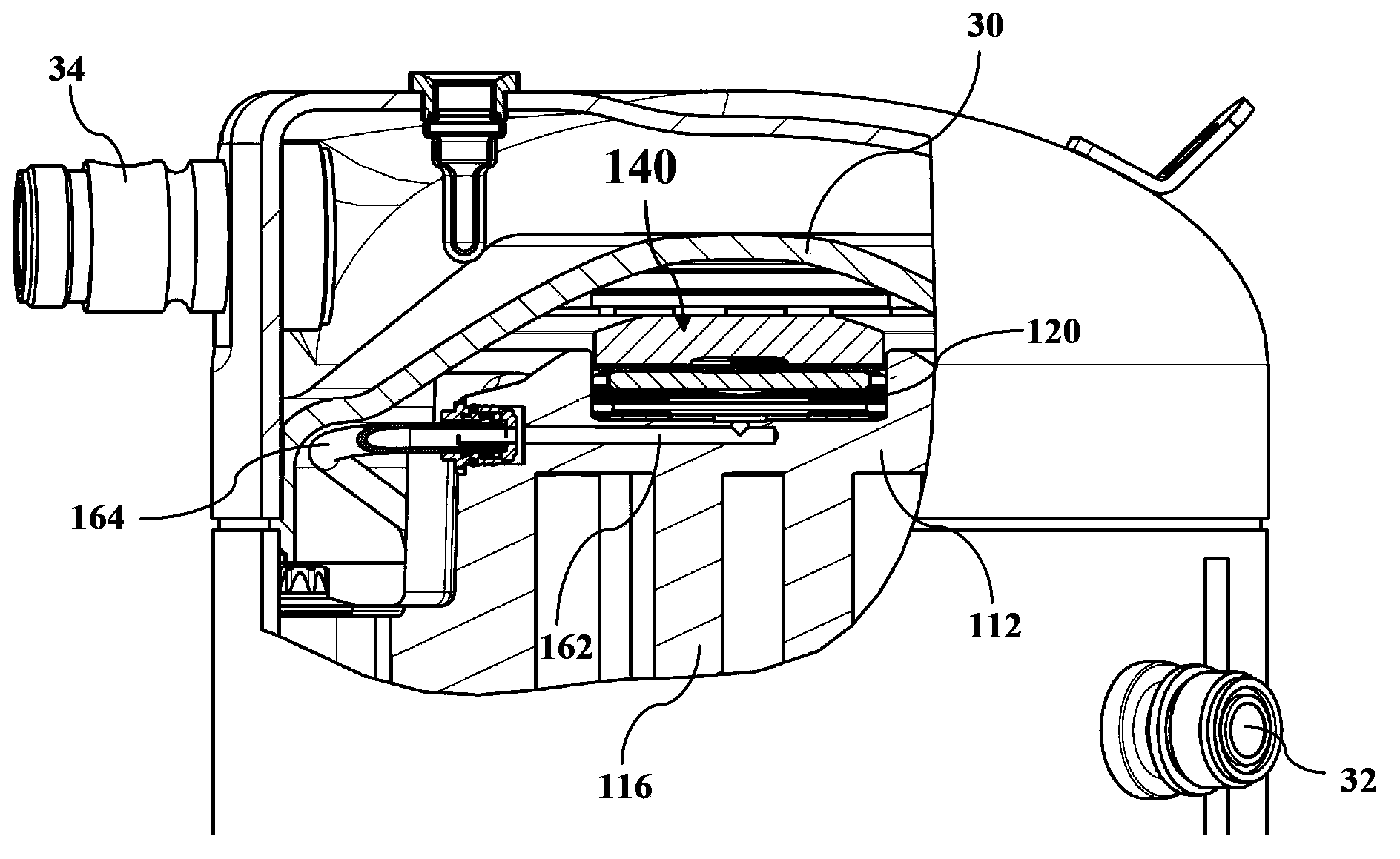

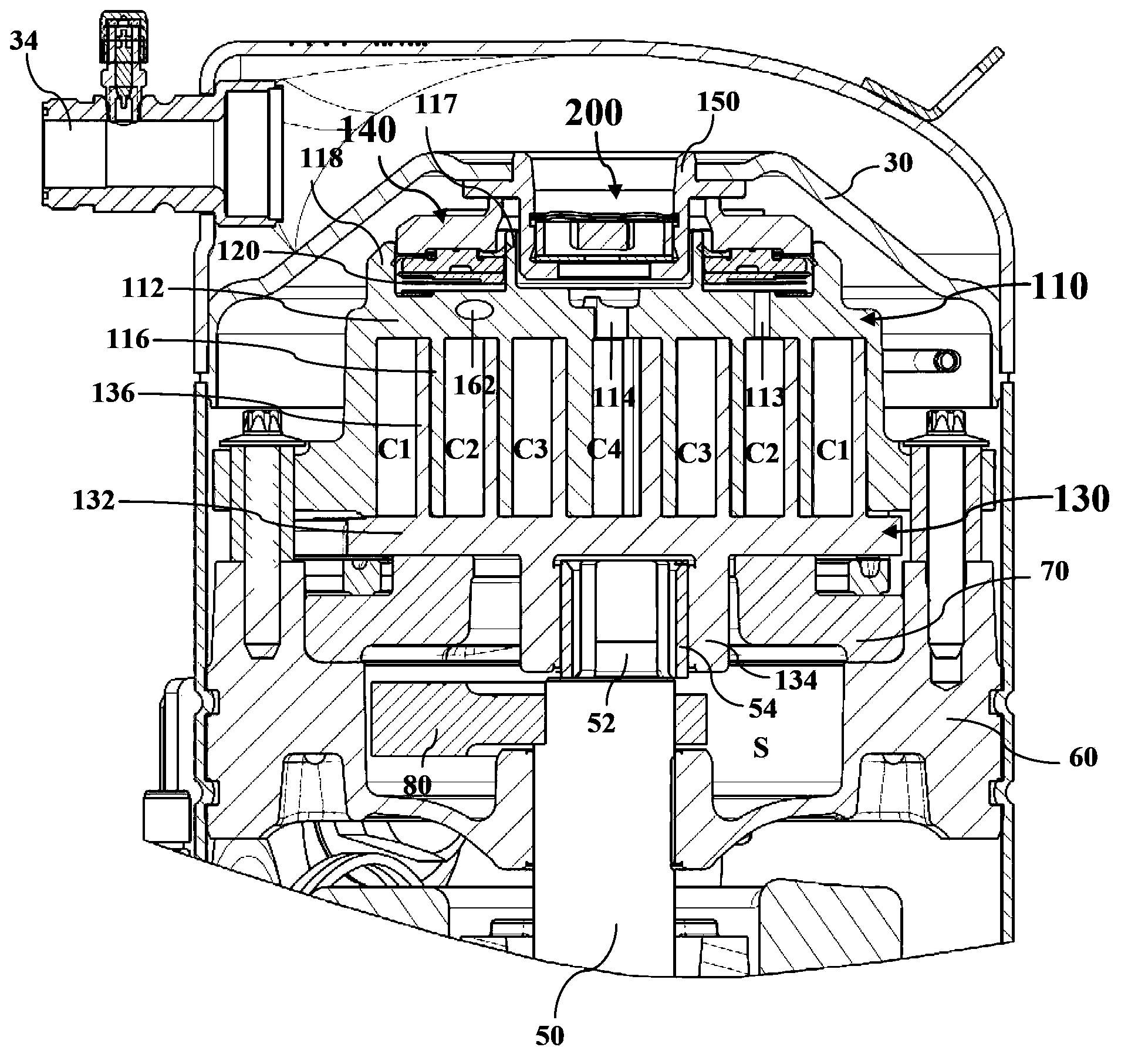

[0027] The following will refer to Figure 1-3 The basic configuration of the compressor according to the first embodiment of the present invention is described. Such as figure 1 As shown, compressor 10 includes a generally closed housing 20 . The housing 20 may be composed of a substantially cylindrical body portion 22 , a top cover 24 disposed at one end of the body portion 22 , and a bottom cover 26 disposed at the other end of the body portion 22 . A partition 30 is provided between the top cover 24 and the body portion 22 to partition the inner space of the housing 20 into a suction side and a discharge side. The space between the partition 30 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com