Air inlet and exhaust valve of compressor

An intake and exhaust valve and compressor technology, applied in the field of compressors, can solve the problems of large valve cavity clearance volume, large gas flow resistance, low vibration noise, etc., and achieve small clearance volume, small flow resistance, and air noise. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

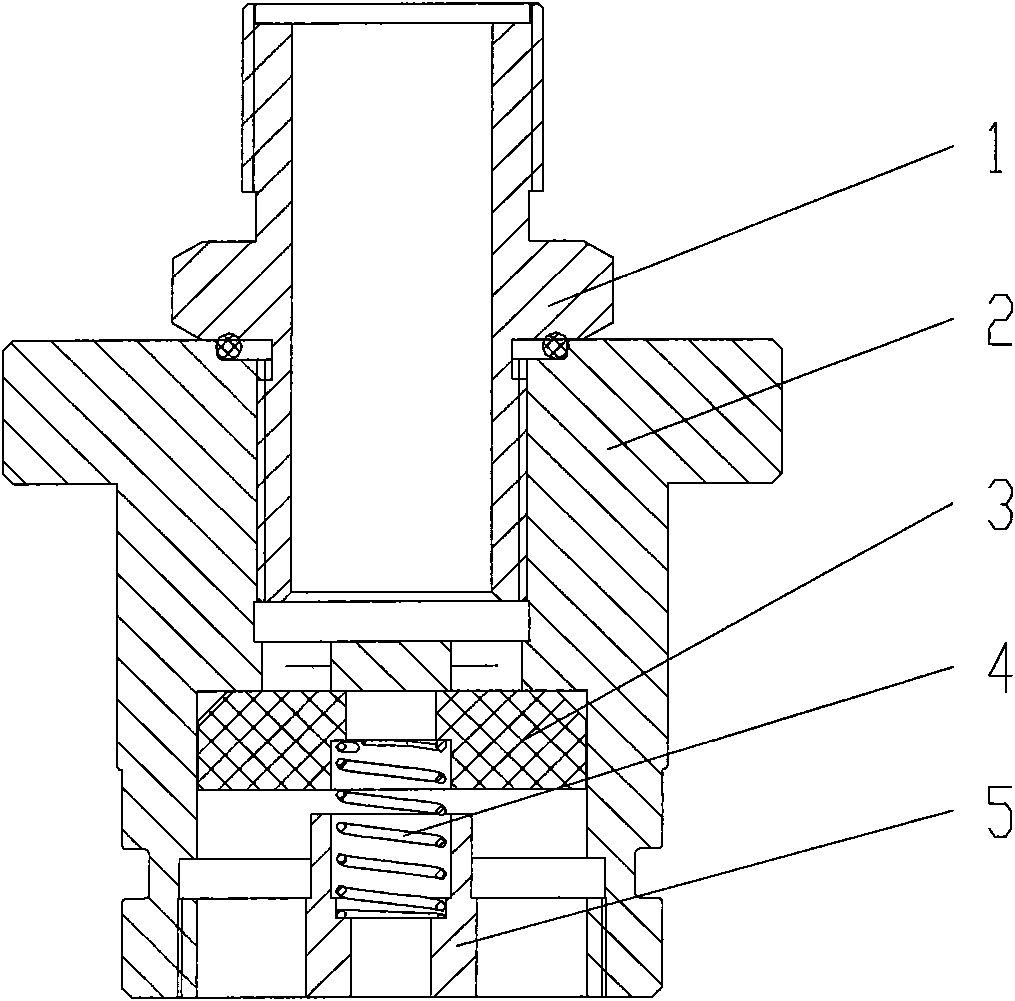

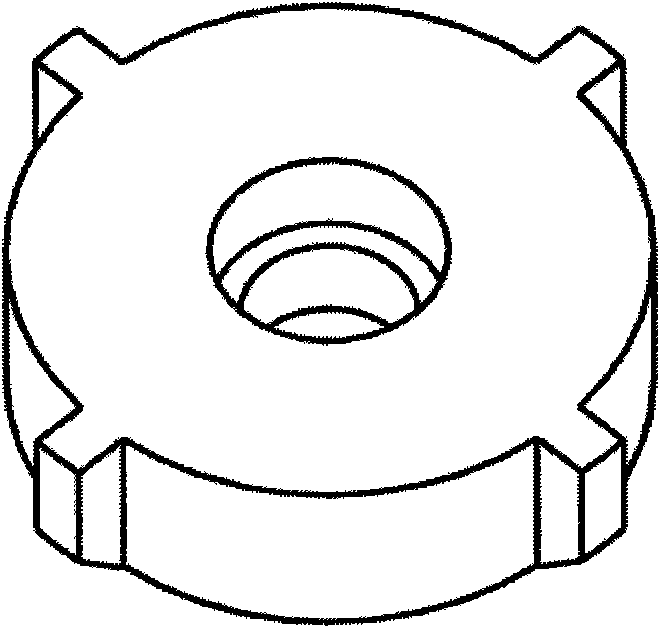

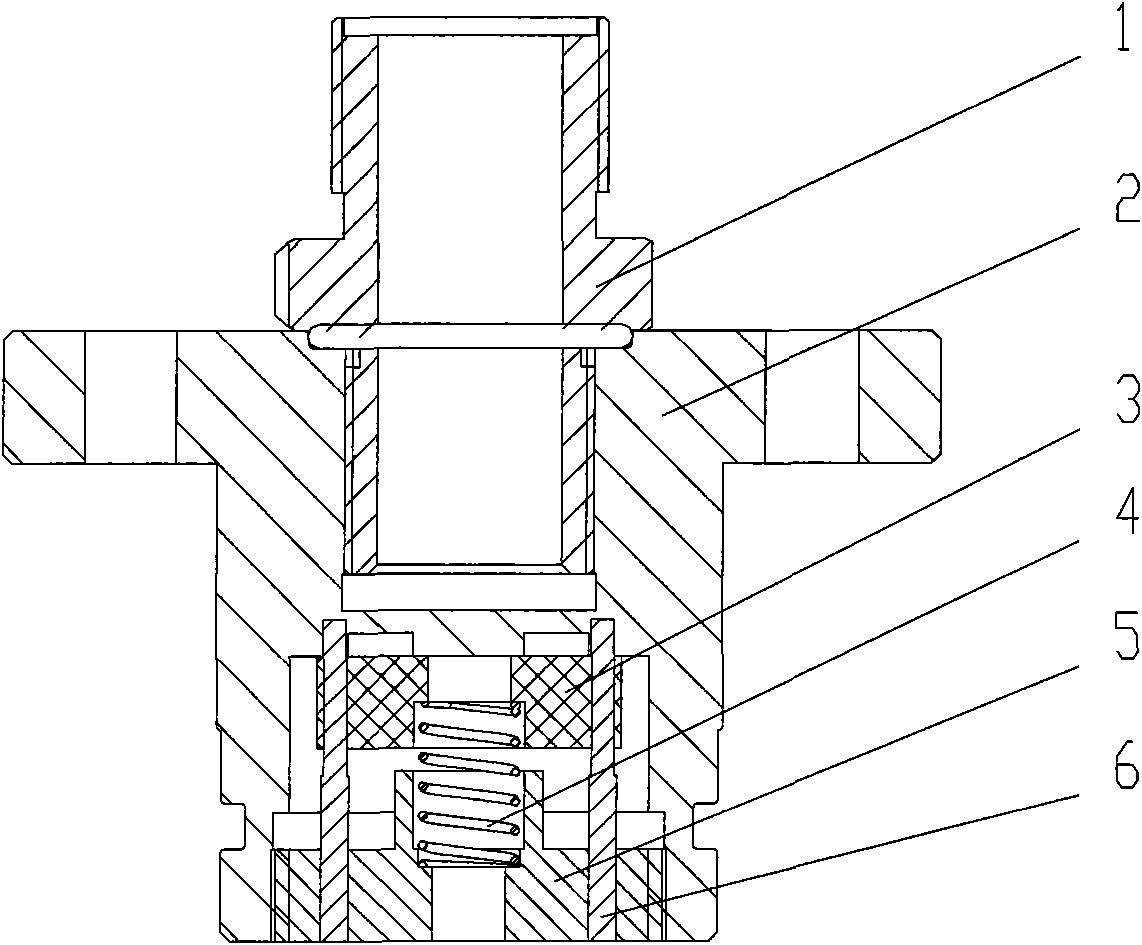

[0026] figure 1 Shown is a cross-sectional view of the main body structure of the intake and exhaust valve of the present invention, which includes components such as a joint 1, a valve body 2, a valve plate 3, a spring 4, and a spring seat 5, and the valve body 2 is a hollow cylindrical structure. Connector 1, valve seat, valve plate 3, spring 4, and spring seat 5 are arranged in sequence from top to bottom. The valve seat is arranged in the center of the valve body 2 and is integrated with the valve body 2. The upper end is provided with an intake and exhaust joint. 1. There are several symmetrical holes on the valve seat to connect the upper and lower ends of the valve seat. The upper end of the air valve plate 3 is closely attached to the valve seat and forms a flat seal. When the compressor is not in working condition, the air valve plate 3 cuts off the flow passages on both sides of the air valve plate so that it cannot circulate. The lower end of the air valve plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com