Method for preparing biogas through activated carbon, kitchen garbage and faeces

A technology of kitchen waste and activated carbon, which is applied in the fields of organic fertilizer, waste fuel, sludge treatment, etc., can solve the problems of low biogas production efficiency per unit area, reduce the amount of domestic garbage removal, and low added value of kitchen waste utilization, and achieve It is conducive to large-scale promotion and application, shortens the anaerobic time, and facilitates management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

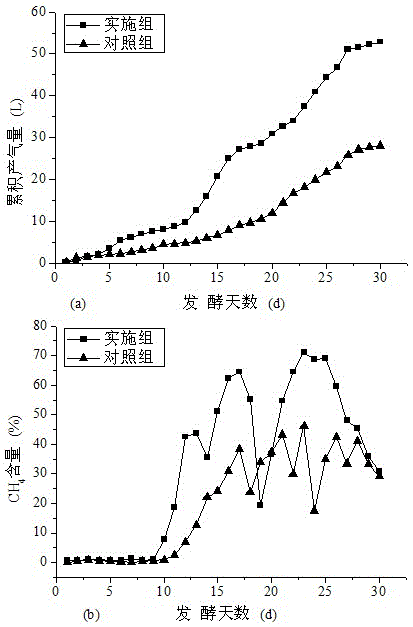

[0036] Embodiment 1: produce biogas according to the following steps

[0037] (1) From the selected domestic waste, sort out the kitchen waste mainly rice and flour food residues, and then put them into the pretreatment tank together with chicken manure at a ratio of 1:1 of total solids, mix and keep the temperature at 35±1°C Heated for 5 hours to obtain a mixture;

[0038] (2) Mix the mixture of the adjusted step (1), sieved into 20-mesh activated carbon and inoculum evenly, and put them into two anaerobic fermentation tanks in turn with a screw flow device to heat at a constant temperature of 35±1°C, and stir for 12 Ferment for 30 days to obtain biogas and fermentation residue respectively; wherein, the amount of activated carbon added is 40% of the total solids of the mixture of kitchen waste and chicken manure obtained in step (1); the inoculum is an old biogas digester with a water content of 92.8% The amount of biogas slurry added is 10% of the total solids of the mixture...

Embodiment 2

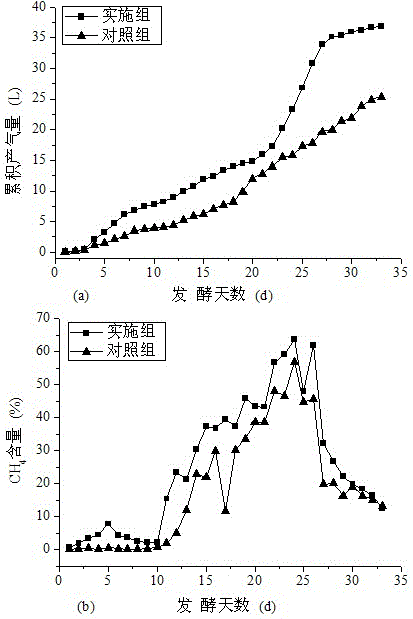

[0042] Embodiment 2: produce biogas according to the following steps

[0043] (1) From the selected domestic waste, sort out the kitchen waste mainly of fruits, vegetables and fruit peels, and then put them into the pretreatment tank together with pig manure according to the total solid content of 1.5:1, mix and heat at a constant temperature of 40±1°C for 6 hours , get a mixture;

[0044] (2) Mix the mixture of the adjusted step (1), sieved into 50-mesh activated carbon and inoculum evenly, and put them into two anaerobic fermentation tanks with a screw flow device in turn to heat at a constant temperature of 40±1°C, and stir for 18 Ferment for 33 days in 1 hour to obtain biogas and fermentation residue respectively; wherein, the amount of activated carbon added is 50% of the total solids of the mixture of kitchen waste and pig manure obtained in step (1); the inoculum is 95.2% of the urban sewage treatment plant Oxygen-digested sludge, the amount added is 12.5% of the tot...

Embodiment 3

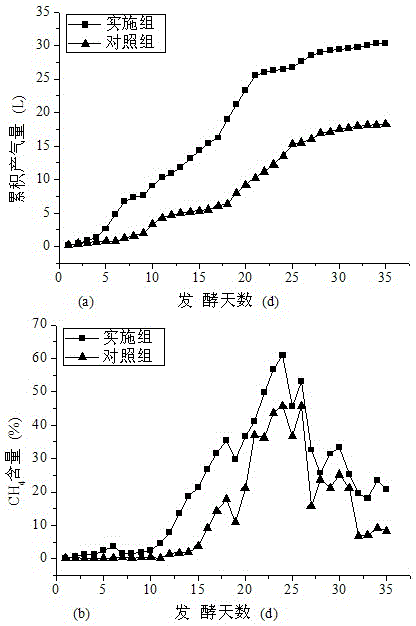

[0048] Embodiment 3: produce biogas according to the following steps

[0049] (1) From the selected domestic waste, sort out the kitchen waste mainly meat, animal and vegetable oil, and then put it into the pretreatment tank together with the cow manure according to the total solid content of 2:1, mix and heat at a constant temperature of 45±1°C for 7 hours, a mixture is obtained;

[0050] (2) Mix the mixture of the adjusted step (1), sieved into 100-mesh activated carbon and inoculum evenly, and put them into two anaerobic fermentation tanks with a screw flow device in turn to heat at a constant temperature of 45±1°C and stir for 24 Ferment for 35 days to obtain biogas and fermentation residue respectively; wherein, the amount of activated carbon added is 60% of the total solids of the mixture of kitchen waste and cow dung obtained in step (1); the inoculum is slaughterhouse sewage with a moisture content of 93.1%. Mud, the amount added is 15% of the total solids of the mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com