Compressor exhaust apparatus

A technology for exhaust devices and compressors, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., and can solve the problem of metal friction between the bearing surface and the piston, high pressure on the valve seat wall, and the bearing surface Solve problems such as sags to achieve the effects of strengthening rigidity, increasing cooling capacity, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

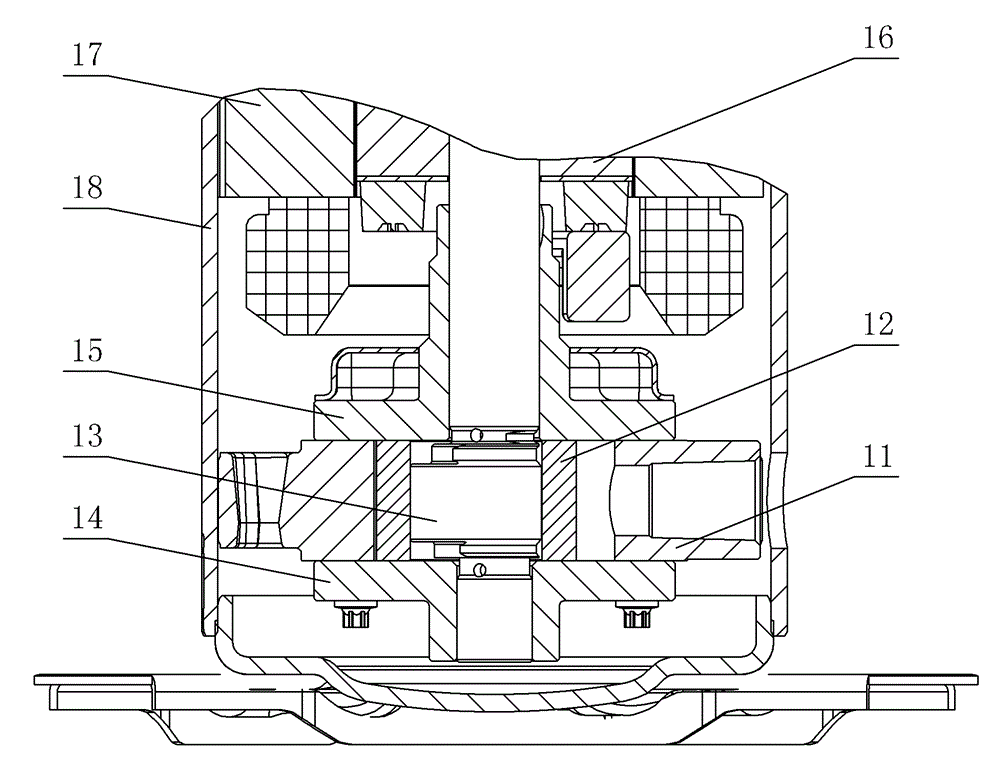

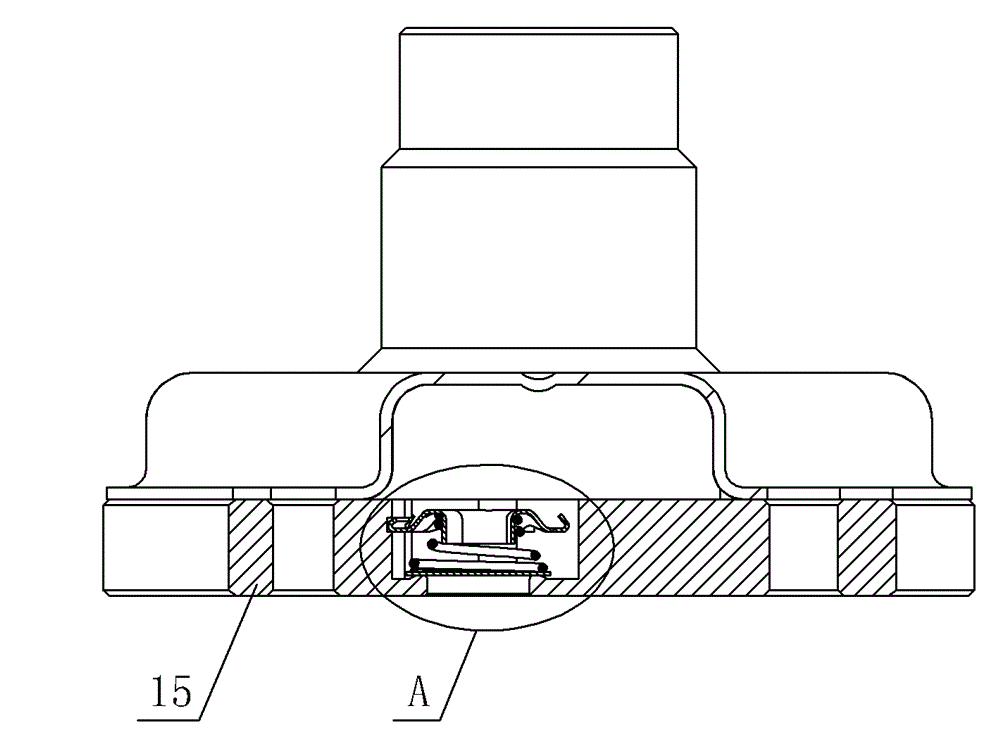

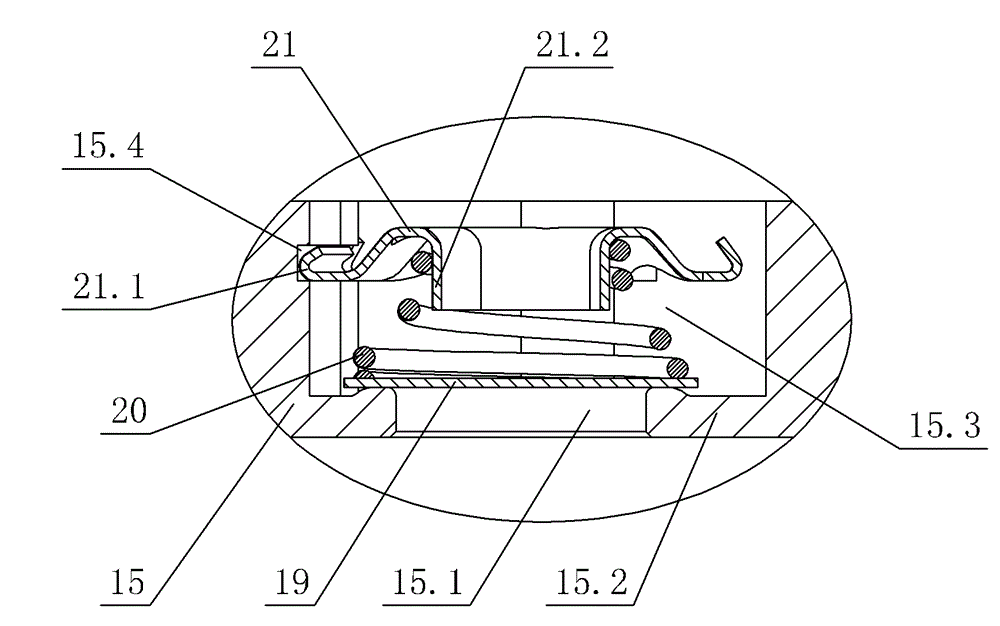

[0026] see Figure 1-Figure 13 , the exhaust device of this compressor, the compressor includes a compression assembly and a motor assembly arranged in a closed casing 18; the compression assembly includes a cylinder 11, a piston 12 arranged in the cylinder 11, and a drive piston 12 for eccentric rotation The eccentric crankshaft 13, the sliding vane arranged in the sliding vane groove of the cylinder 11, the main bearing 15 and the auxiliary bearing 14 respectively arranged on both sides of the cylinder 11; one end of the sliding vane is in contact with the outer circumference of the piston 12; the motor assembly includes a stator 17 And the rotor 16, the stator 17 is fixed on the inner wall of the closed housing 18, and the rotor 16 is fixed on the eccentric crankshaft 13. The exhaust device includes a bearing valve seat 15.2 arranged on the main bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com