Method for changing kitchen garbage into fertilizer

A kitchen waste conversion technology, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of restricting the composting process, serious odor pollution, and slow temperature rise, so as to reduce the generation of leachate and achieve considerable economic benefits. Benefits, simple operation

Active Publication Date: 2012-12-19

CHINA AGRI UNIV

View PDF3 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

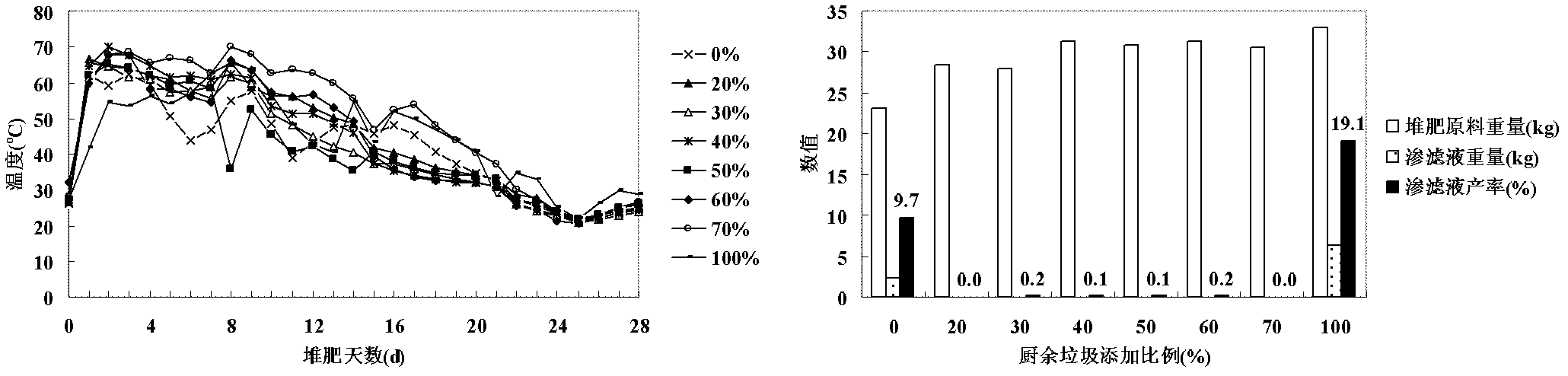

However, due to the high water content of kitchen waste itself, and the water generated by the decomposition of organic matter fills the compost body, the temperature rises slowly during the composting process, a large amount of leachate is produced, and the odor pollution is serious, which greatly restricts the composting process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0042] 1. Composting method

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

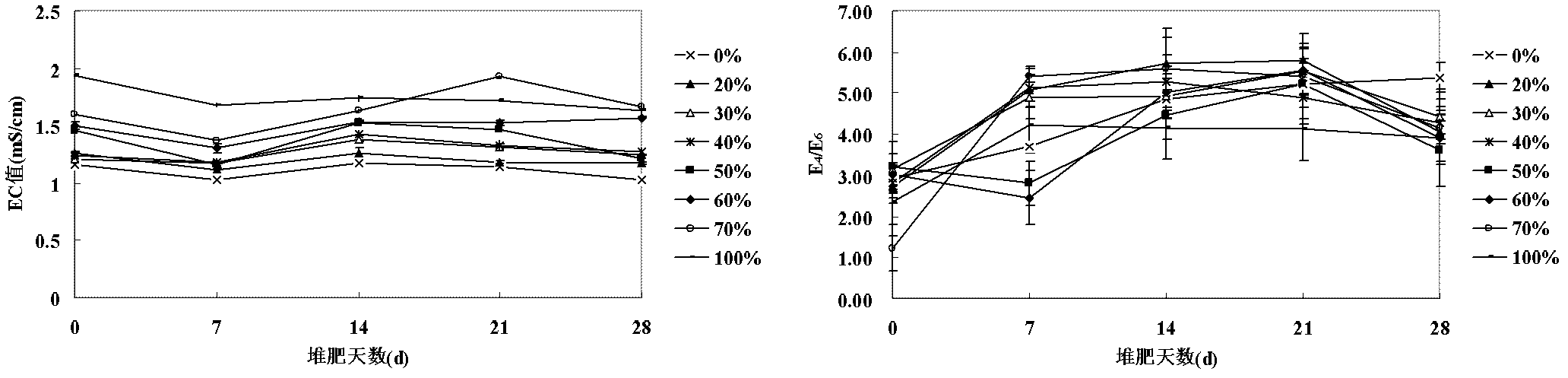

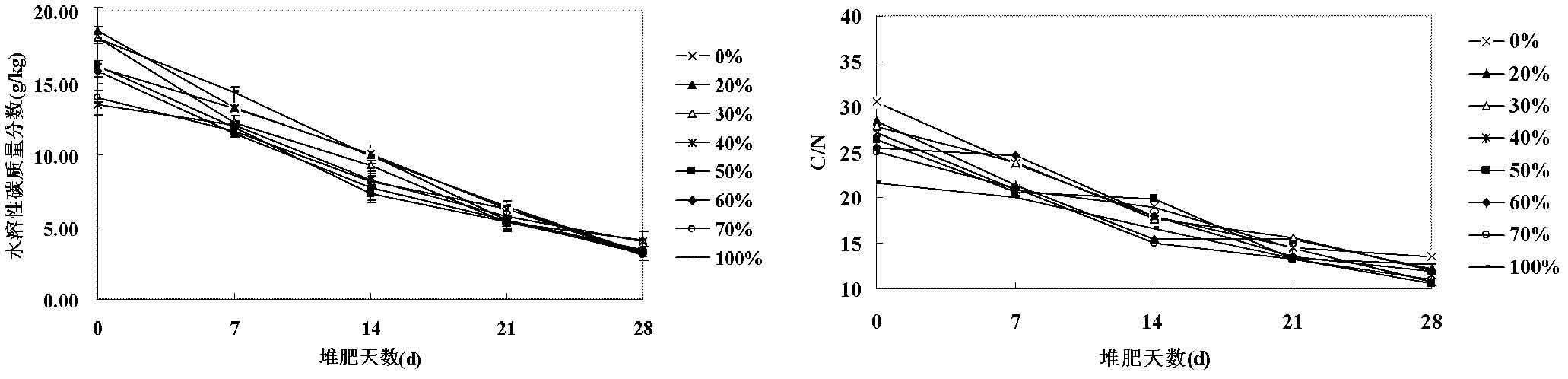

The invention discloses a method for changing kitchen garbage into a fertilizer. The method provided by the invention comprises the following steps of: mixing livestock manure, crop straw and kitchen garbage to obtain a mixture; and fermenting the mixture to obtain the fertilizer. An appropriate proportion of kitchen garbage is added into pig manure and straw which are used as main materials of compost, thus solving problems of unventilated defect, slow heating and generation of a lot of leachate and the like by individually composting. It shows through a fermenter composting test that heating speed of compost can be accelerated by the addition of residual kitchen garbage into straw and pig compost and simultaneously the generation of leachate can be greatly minimized. Germination rate indexes of residual kitchen garbage compost products added in any proportion are all greater than 80%, and the compost products all reach the putrescibility standard. Considering temperature, leachate, putrescibility and odor discharge together as a whole, the percentage of the added residual kitchen garbage is supposed to be controlled within 30% to 60%. In addition, by the adoption of the method, delivering quantity of house refuse can be effectively minimized, resources are saved, generation of malodorous gases is controlled, and the goal of energy saving and emission reduction is realized.

Description

technical field [0001] The invention relates to a method for converting kitchen waste into fertilizer. Background technique [0002] Kitchen waste is waste from residents' living process. In recent years, with the rapid development of my country's economy and the improvement of people's living standards, the generation of kitchen waste has continued to increase, and the environmental pollution problems caused by it have become increasingly serious. How to effectively deal with kitchen waste has become a major issue that must be faced at home and abroad. environmental conundrum. [0003] At present, the relatively mature kitchen waste treatment technologies at home and abroad mainly include the following methods: 1. Landfill. Landfill can reduce waste, but kitchen waste is mainly composed of carbohydrates, vegetable leaves, and fruit peels, with high water content, and landfill is prone to produce a large amount of leachate, which seriously pollutes groundwater; 2. Incinerat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C05F17/00C05F15/00

CPCY02W30/40

Inventor 李国学高丹张玮张红玉

Owner CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com