Spherical ball expander

A technology of spherical balls and expanders, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as failure to carry out large-scale commercial production, stay in the theoretical and experimental stage, and imperfect structural design, etc., to achieve Save settings, compact structure, and small clearance volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

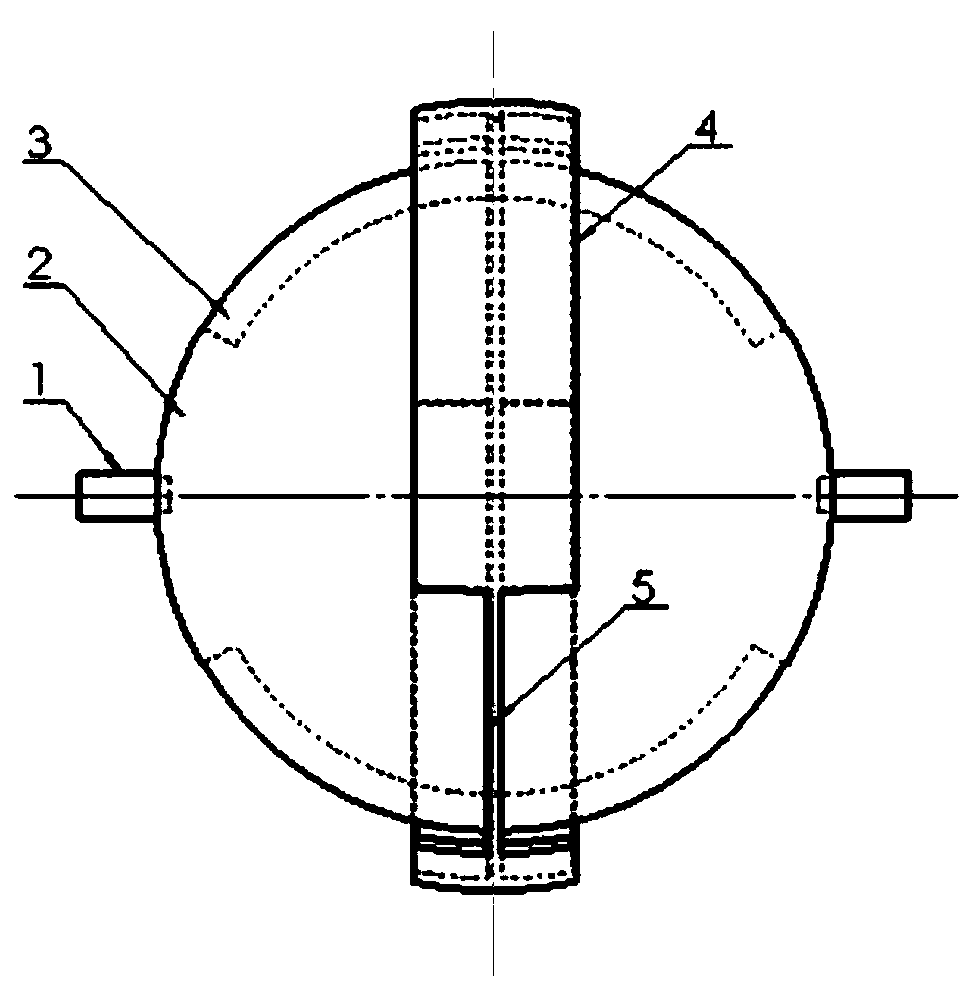

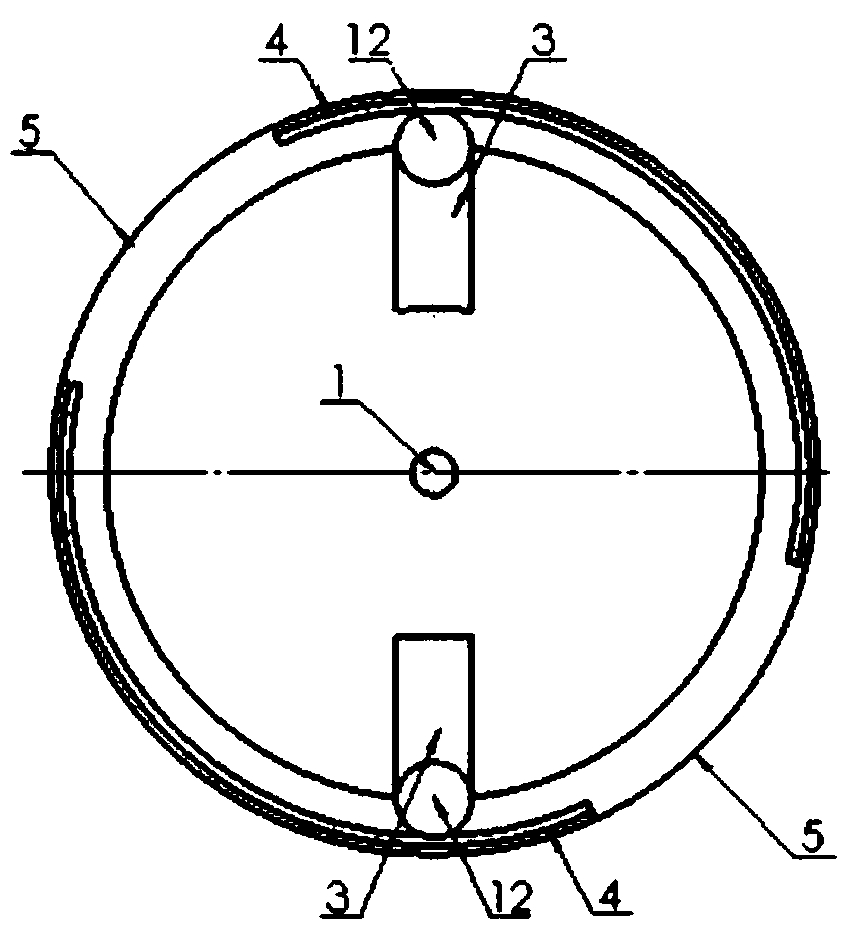

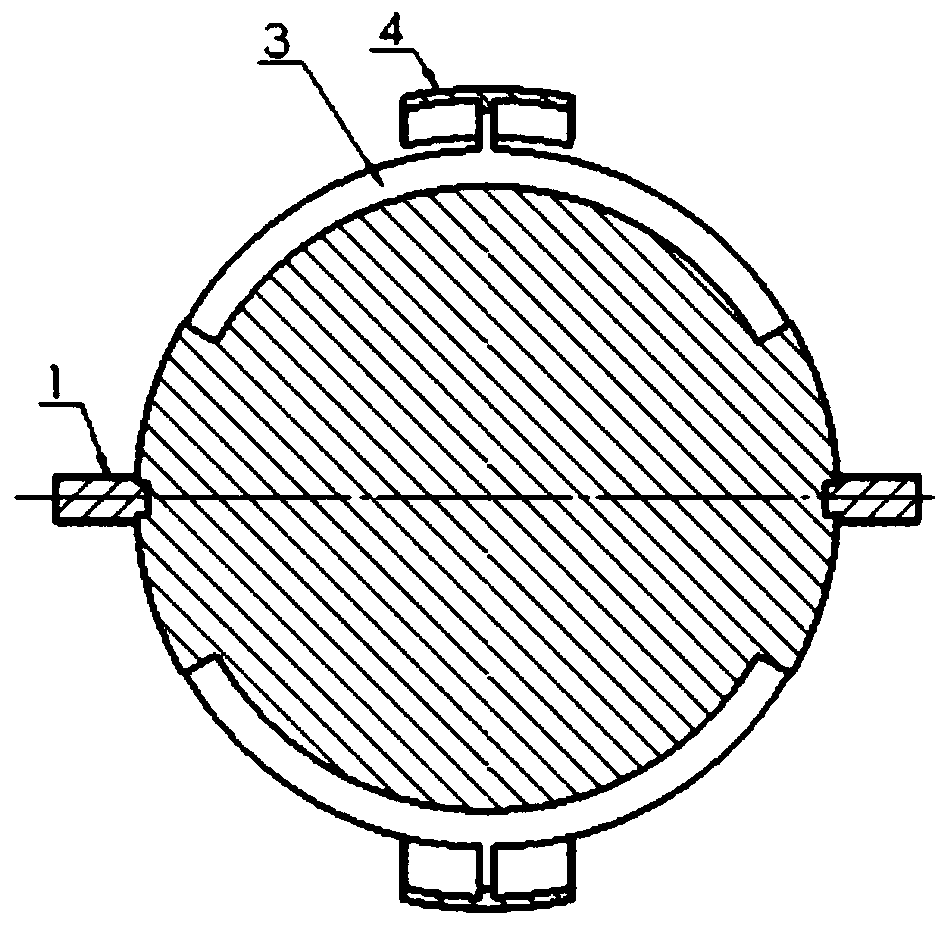

[0034] Such as Figure 1-16 As shown, the spherical ball expander includes a spherical shaft 1, a spherical body 2, a spherical arc groove 3, a T-shaped convex ring 4, a rectangular convex ring 5, a shaft hole 6, a spherical shell 7, a spherical T-shaped concave ring 8, and a spherical shell ring Groove 9, air inlet 10, ball 11, convex ring notch 12, spherical shell groove intersection 13, exhaust port 14.

[0035] The sphere 2 is concentric with the spherical shell 7, and the outer diameter of the sphere 2 is slightly smaller than the inner diameter of the spherical shell 7 so that the sphere 2 can rotate in the spherical shell 7.

[0036] Such as Figure 1-Figure 4 As shown, the outer surface of the sphere 2 is provided with two symmetrical sphere arc grooves 3 and a sphere protruding ring perpendicular to the sphere arc groove 3, the sphere protruding ring is two sphere T-shaped protruding rings 4 and two sphere rectangular protruding rings 5 Integral convex rings of alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com