Adsorption type refrigeration system based on enhanced mass transfer

An adsorption refrigeration and adsorption bed technology, which is applied in refrigerators, refrigeration components, adsorption machines, etc., can solve the problems of large adsorption refrigeration units, difficult vacuum maintenance, and decreased system stability, etc., to improve the cycle adsorption. volume and thermal conductivity, compact structure, reducing the effect of pipeline connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be further described below in conjunction with specific embodiments and drawings, but the implementation of the present invention is not limited thereto.

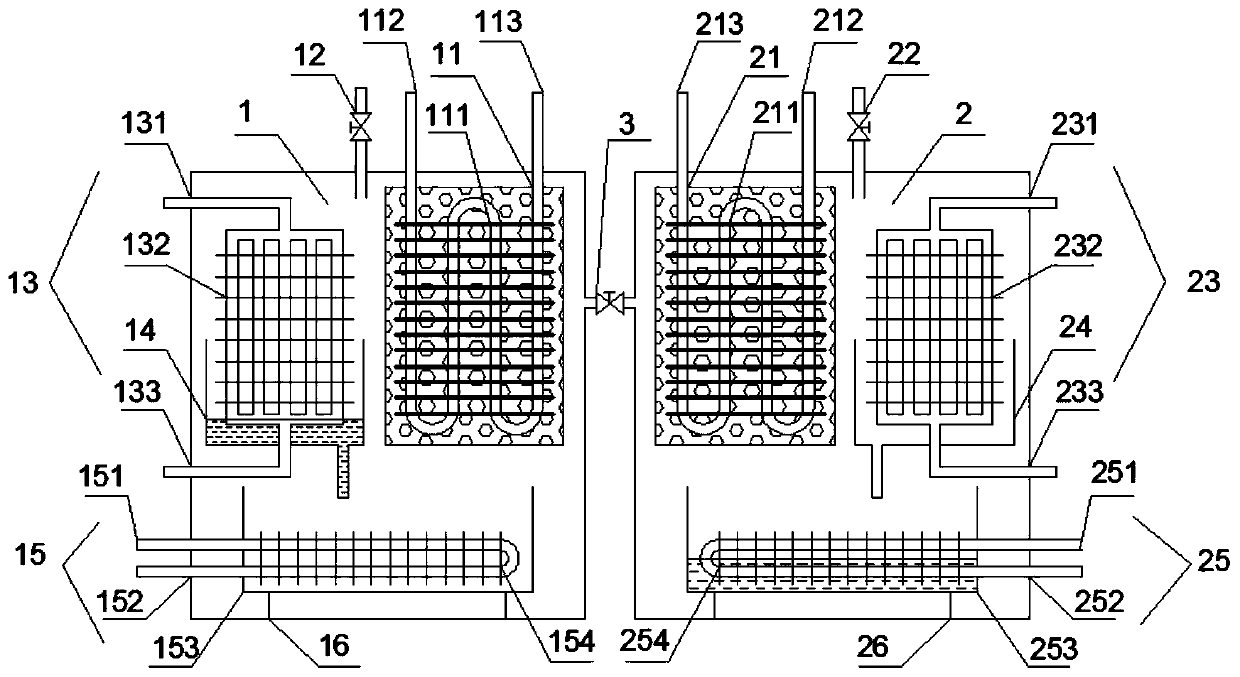

[0029] combine figure 1 , this implementation case describes the adsorption refrigeration system in detail, its structure includes: two independent chambers of the first working chamber 1 and the second working chamber 2, the first working chamber 1 and the second working chamber 2 pass through the vacuum valve 3 connect. The vacuum valve 3 is used to complete the mass transfer process between the first working chamber and the second working chamber.

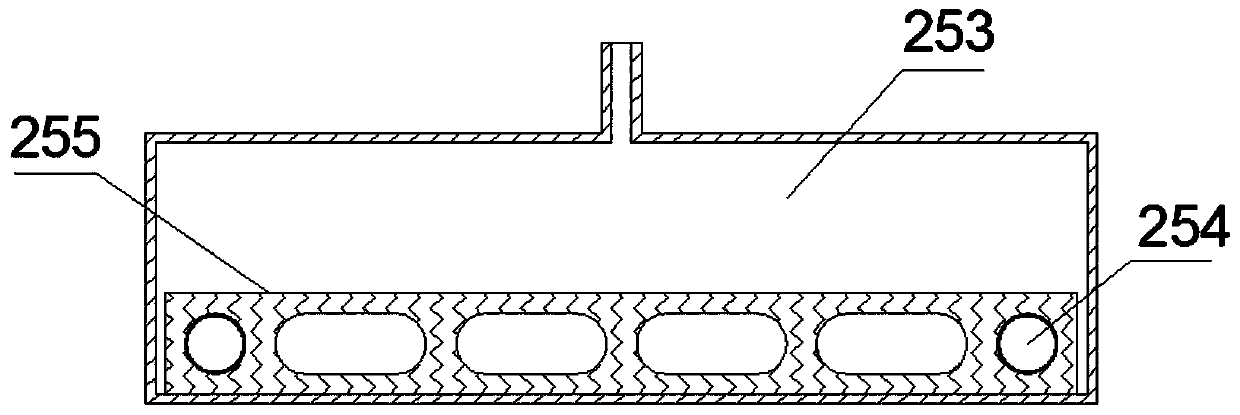

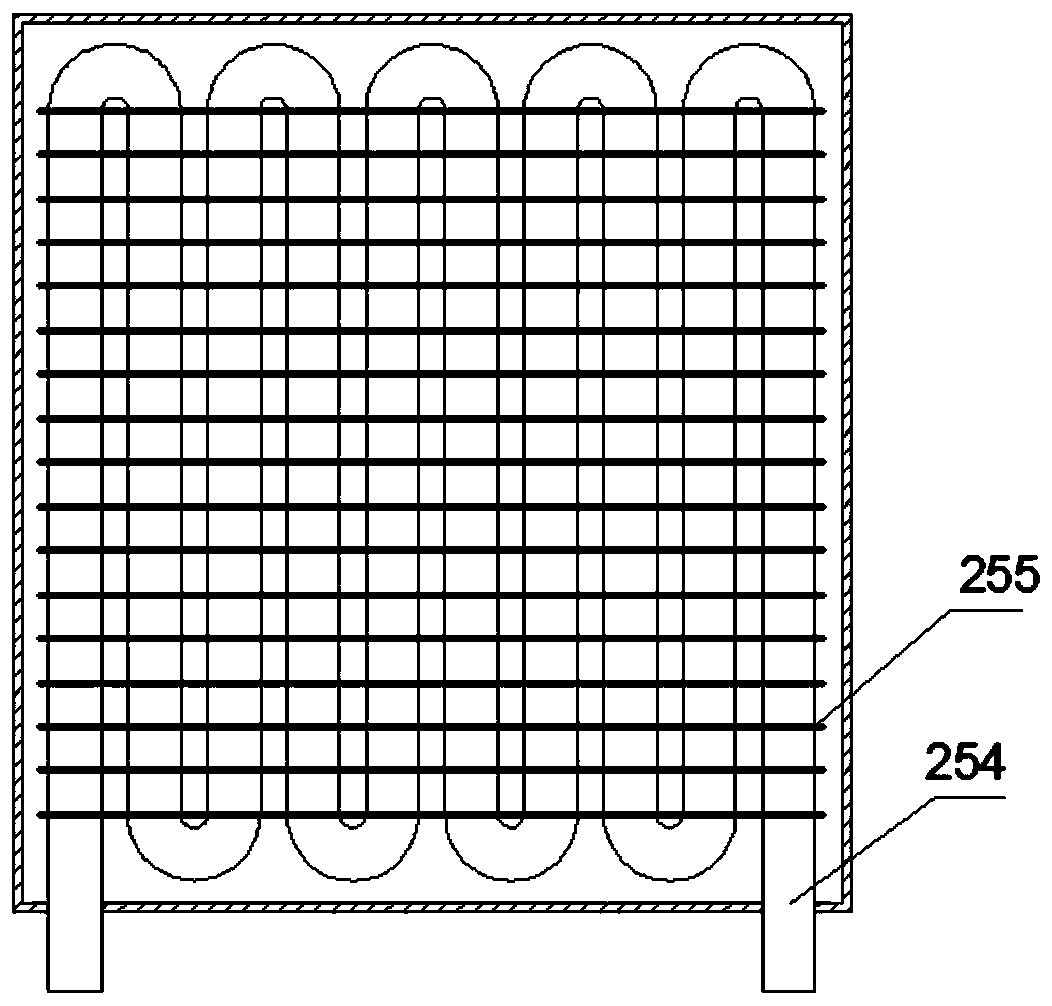

[0030] The first working chamber 1 comprises a first adsorption bed 11, a first condenser 13, a first liquid reservoir 14 and a first evaporator 15, and the first condenser 13 is arranged on the left side of the first adsorption bed 11 in the horizontal direction On the side, the first liquid receiver 14 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com