Liquid sucking core component of AMTEC (alkali metal thermoelectric converter) and manufacturing method thereof

A liquid-absorbing core and converter technology, which is applied in capacitor parts, temperature-sensitive equipment, etc., can solve the problems of high resistance along the process, increased manufacturing processes and steps, and interruption of alkali metal liquids, etc., so as to reduce the resistance along the process. The effect of reducing the production process and simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

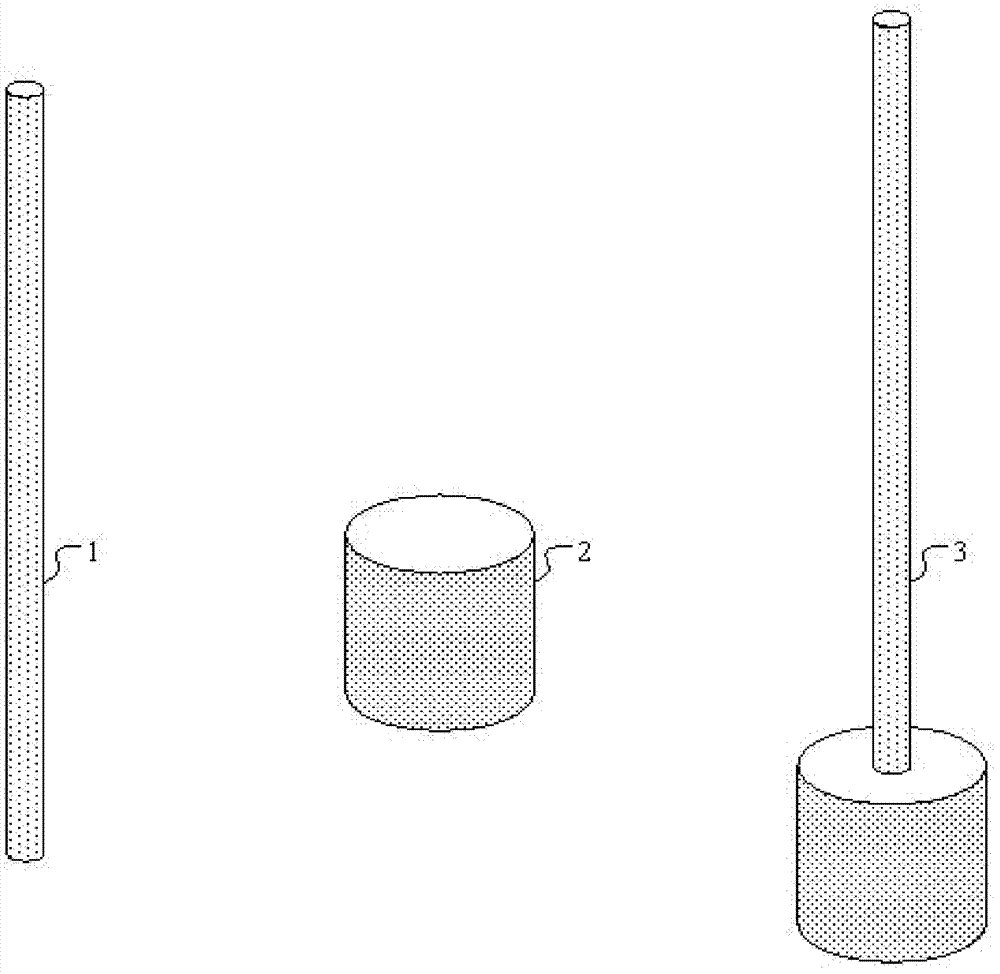

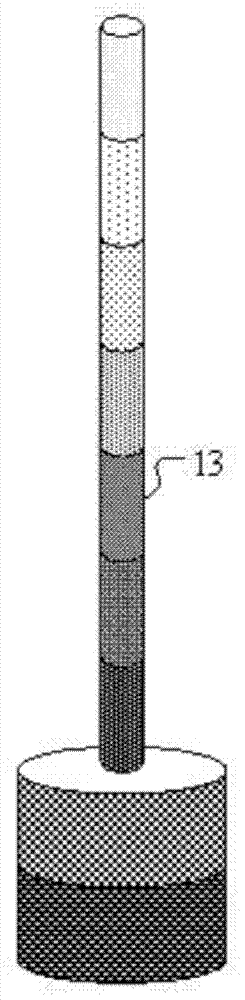

[0015] The invention provides a method for integrally manufacturing a liquid-absorbing core assembly of an alkali metal thermoelectric converter. The specific implementation method will be described below with reference to the accompanying drawings.

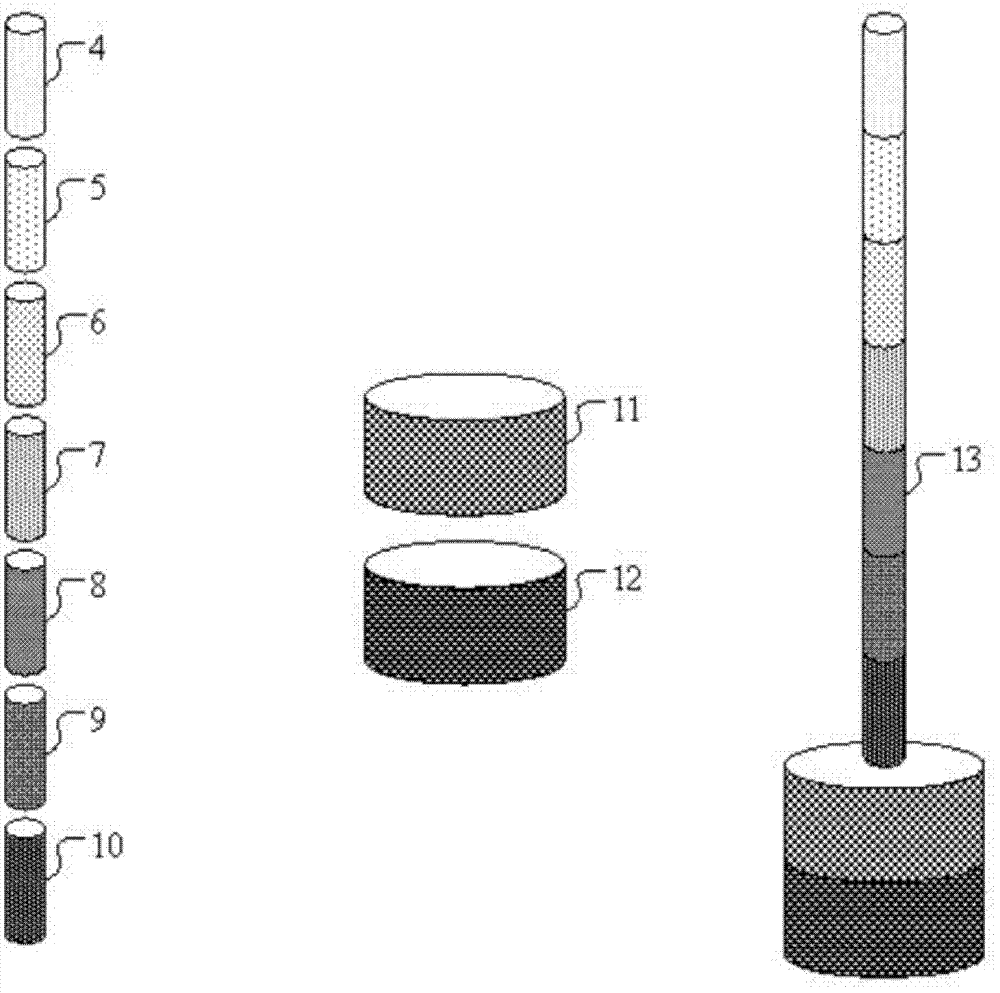

[0016] image 3 As shown, seven pieces of 10 mm in length, different pore diameters, and press-formed columnar metal powder blocks 4 to 10 are used to make the liquid-absorbing core part, and two 10-mm-length, different pore diameters, pressed and formed blocks are used to make the evaporator part. Columnar metal powder blocks 11 to 12; the apertures of the nine metal powder blocks are different from each other, and the apertures of the nine metal powder blocks decrease sequentially from the metal powder block 4 to the metal powder block 12, put the nine m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com