Vibration total heat exchanger for enhancing heat transfer

A total heat exchanger and heat transfer technology, applied in the directions of household heating, heating methods, household heating, etc., can solve the problems of rising cost and price of heat exchangers, increased fluid pressure loss, and increased installation weight, etc. Less internal support, less wind pressure loss, and less resistance along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

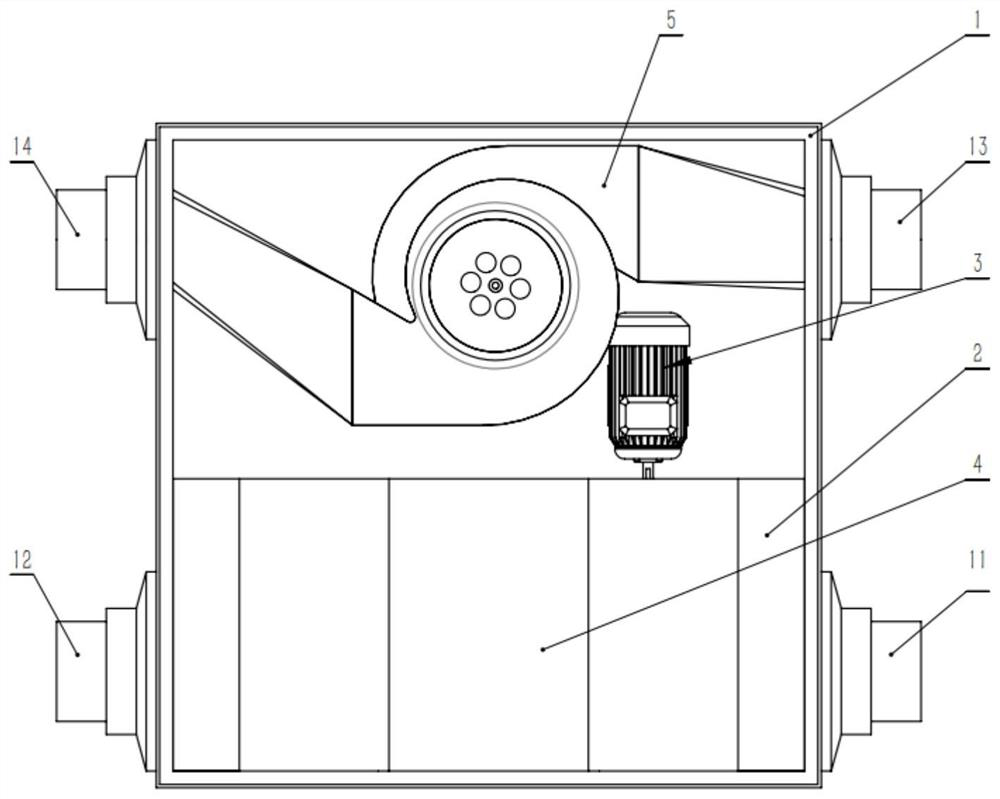

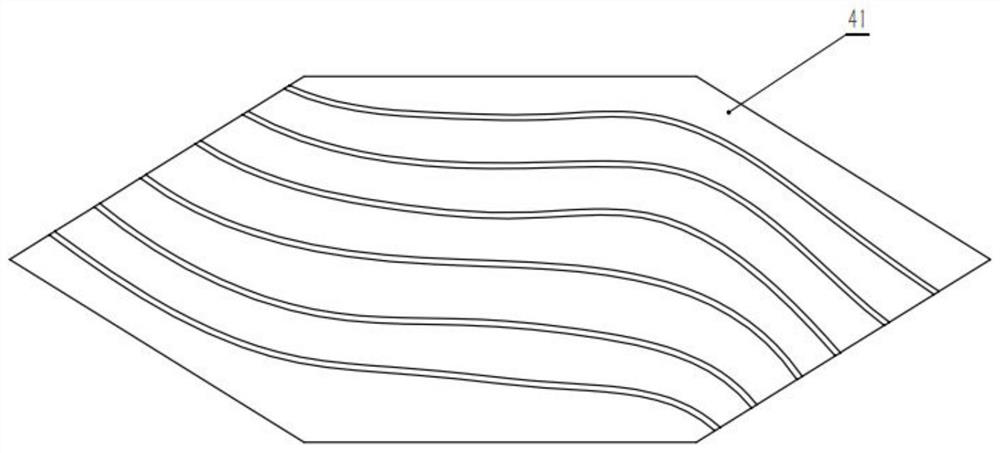

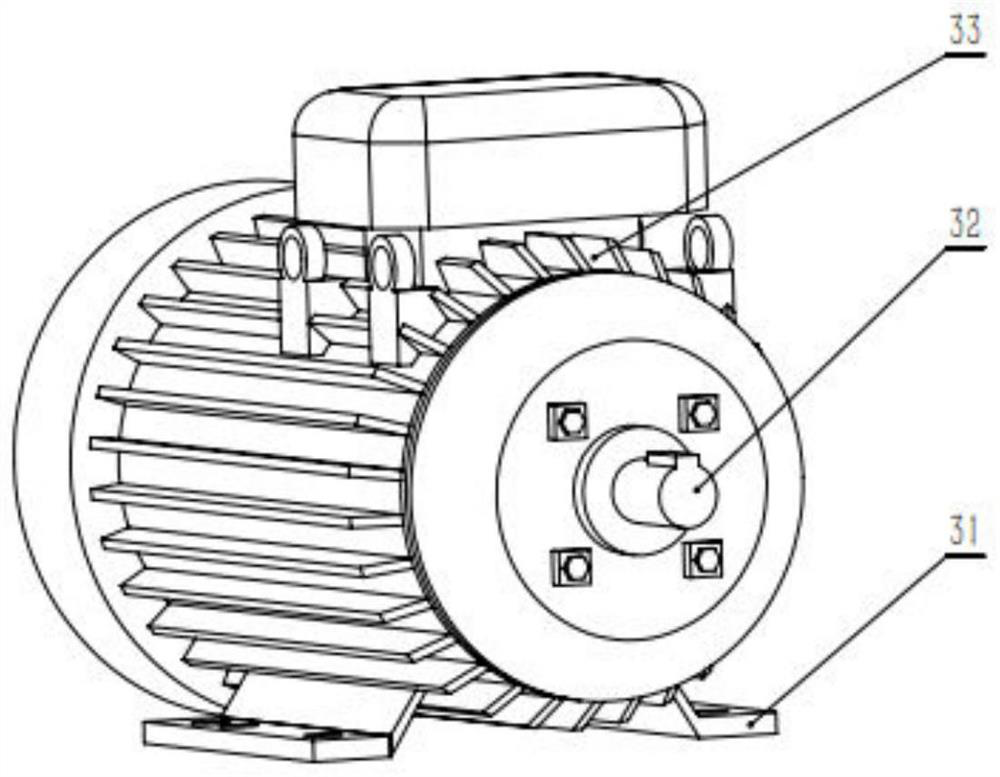

[0021] Such as Figure 1-4 As shown, a vibrating total heat exchanger that enhances heat transfer includes a noise reduction casing 1, an outdoor air inlet 11, an indoor air outlet 14, an indoor air inlet 12, an outdoor air outlet 13, a filter screen 2, and a heat exchange core 4 and a double-layer fan 5; the noise reduction casing 1 is provided with a sound insulation layer; the outdoor air inlet 11 and the indoor air outlet 14 are all located on the right side of the noise reduction casing 1, and the indoor air outlet 14 is located at the outdoor air inlet The top of the air inlet 11; the indoor air inlet 12 and the outdoor air outlet 13 are located on the left side of the noise reduction casing 1, and the outdoor air outlet 13 is located above the indoor air inlet 12; and in the present embodiment, the filter screen 2 The quantity is 1 pair, the pair of filter screens 2 are not in contact with each other, and the pair of filter screens 2 are fixedly connected to the noise r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com