Micro-channel anode water mist removing device

A technology of micro-channel and water mist, which is applied in the direction of electrode structure and electrostatic separation, can solve the problems of unsatisfactory dust removal effect of electrostatic precipitator, large resistance along the process of adsorbing charged particles, and adsorption of cathode and anode together. The effect of low production cost and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

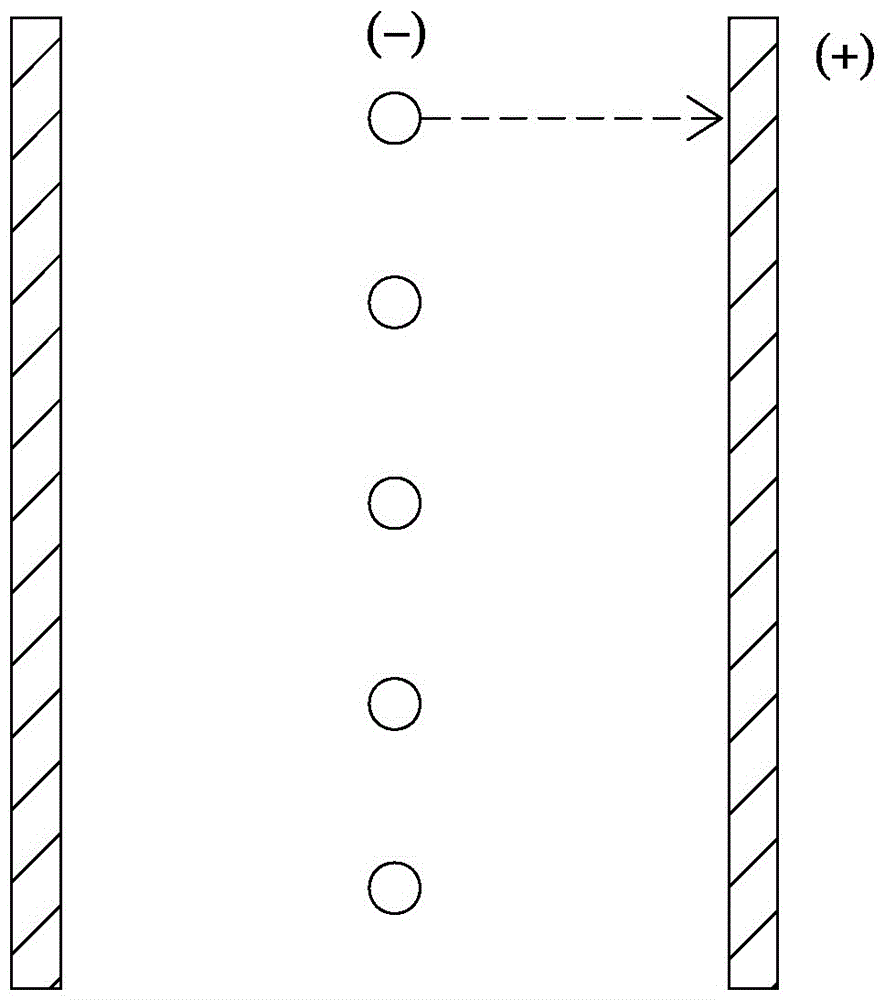

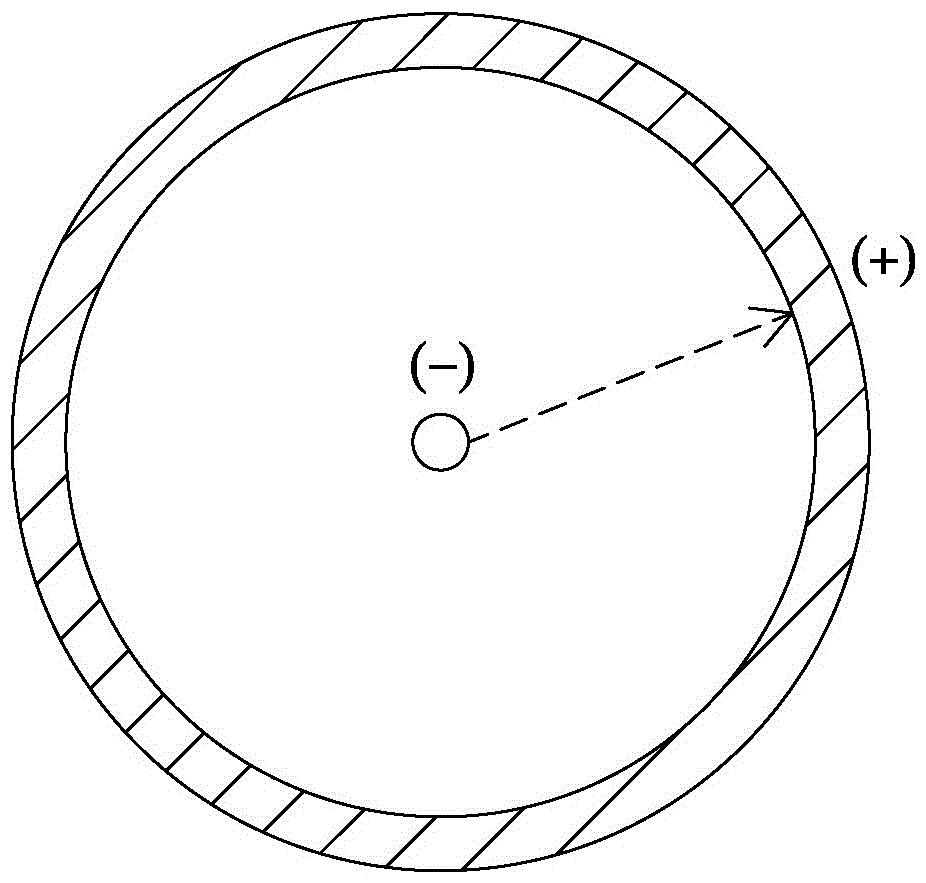

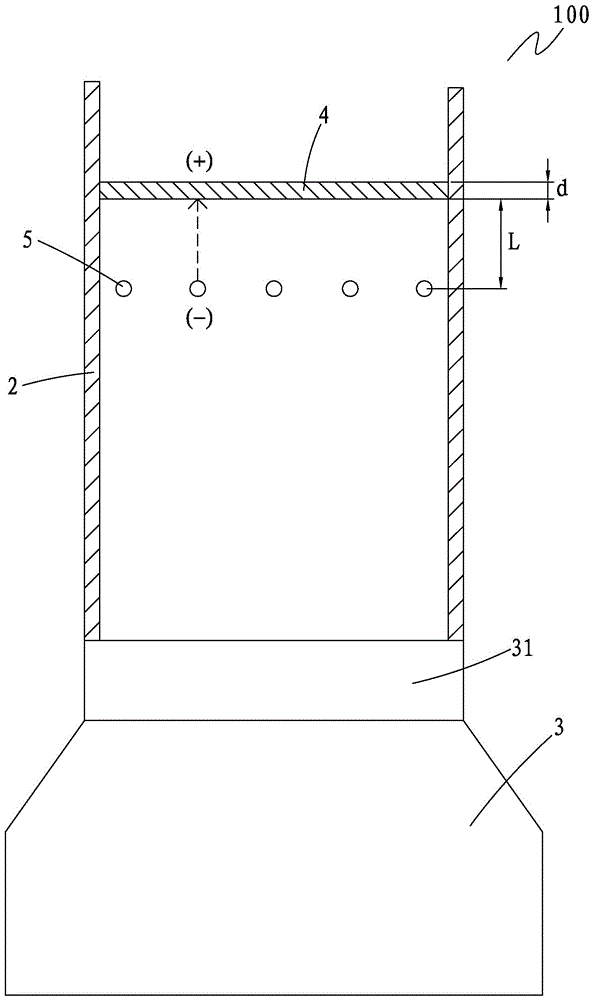

[0032] Please refer to Figure 3 to Figure 5 As shown, a microchannel anode water mist removal device 100 includes a high-voltage electrostatic power supply 1, a columnar cylinder 2, a device 3 for centralized discharge of water mist, a screen anode plate 4, and several cathode wires 5; The wire mesh anode plate 4 is an anode plate with micro-channels 42 formed by interweaving and stacking several metal wires 41; the columnar cylinder 2 communicates with the water mist outlet 31 of the equipment 3 for centralized water mist discharge; The mesh anode plate 4 is arranged laterally inside the columnar body 2; each of the cathode lines 5 is arranged laterally inside the columnar body 2, and the cathode line 5 is located on the inside of the wire mesh anode plate 4. Below: the negative pole of the high-voltage electrostatic power supply 1 is connected to the cathode line 5 , and the positive pole is connected to the screen anode plate 4 .

[0033] The voltage provided by the high-...

specific Embodiment 2

[0035] The difference from the first embodiment is that in the second embodiment, the voltage provided by the high-voltage electrostatic power supply 1 is 20KV; the diameter of the metal wire 41 is 1 mm; the wire mesh anode plate 4 and the cathode wire The distance L between 5 is 100 mm; the diameter of the microchannel 42 is 2.5 mm; the thickness d of the screen anode plate 4 is 20 mm.

specific Embodiment 3

[0037] Different from the specific embodiment one, in the specific embodiment three, the voltage provided by the high-voltage electrostatic power supply 1 is 16KV; the diameter of the metal wire 41 is 0.4mm; the wire mesh anode plate 4 and the cathode The distance L between the wires 5 is 60 mm; the diameter of the microchannel 42 is 1.2 mm; the thickness d of the wire mesh anode plate 4 is 10 mm.

[0038] In summary, the present invention has the following beneficial effects: 1. The distance between the screen anode plate and the cathode line is short, which can greatly reduce the resistance along the water mist particles, increase the adsorption speed, reduce time consumption, and only It is necessary to provide a micro voltage of 10 ~ 20KV to meet the adsorption requirements, which can reduce the consumption of electric energy; 2. The wire mesh anode plate is arranged horizontally inside the cylindrical cylinder, so that the charged air containing the water mist factor needs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The way to | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com