Automatic elbow inserting machine

An elbow, automatic technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient insertion of the elbow, high maintenance cost, difficult control, etc., and achieves fast working speed and high degree of automation. , arrange high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

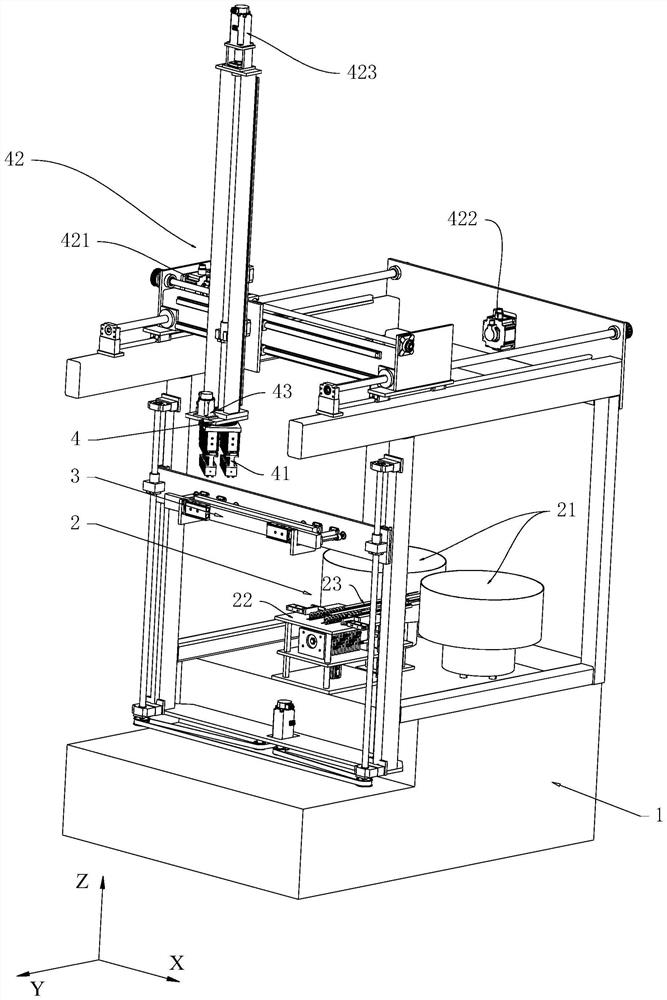

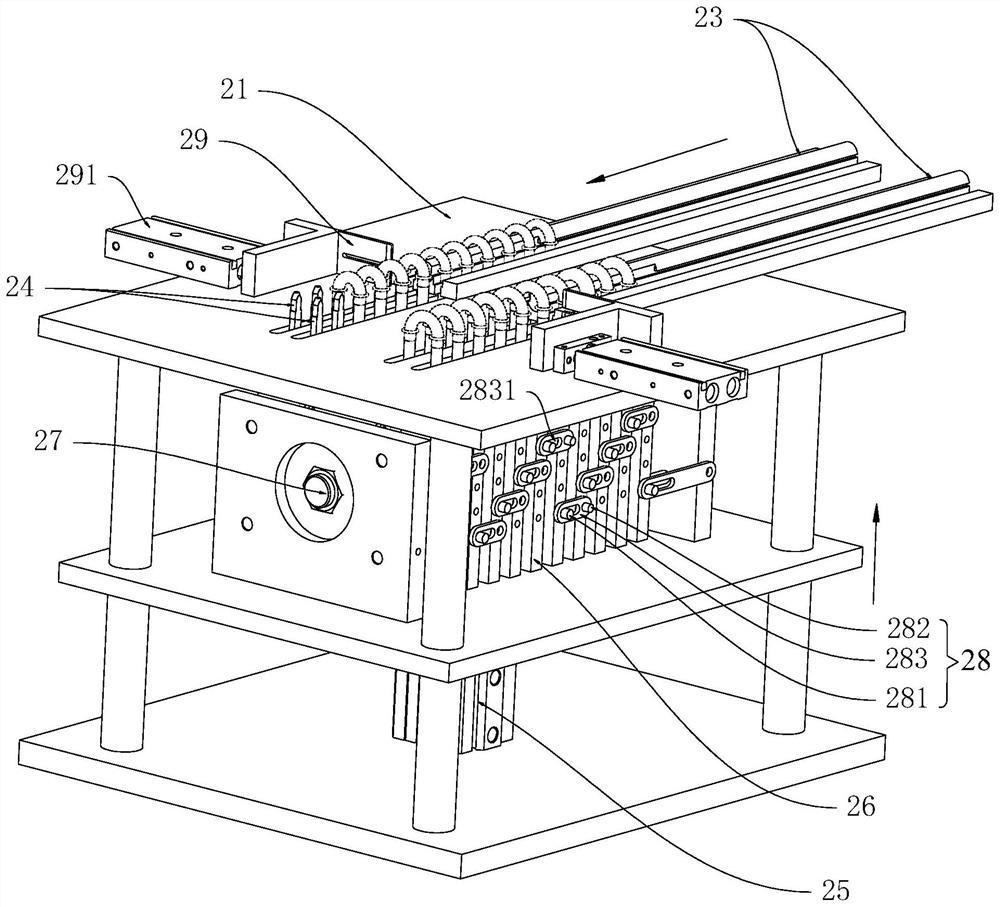

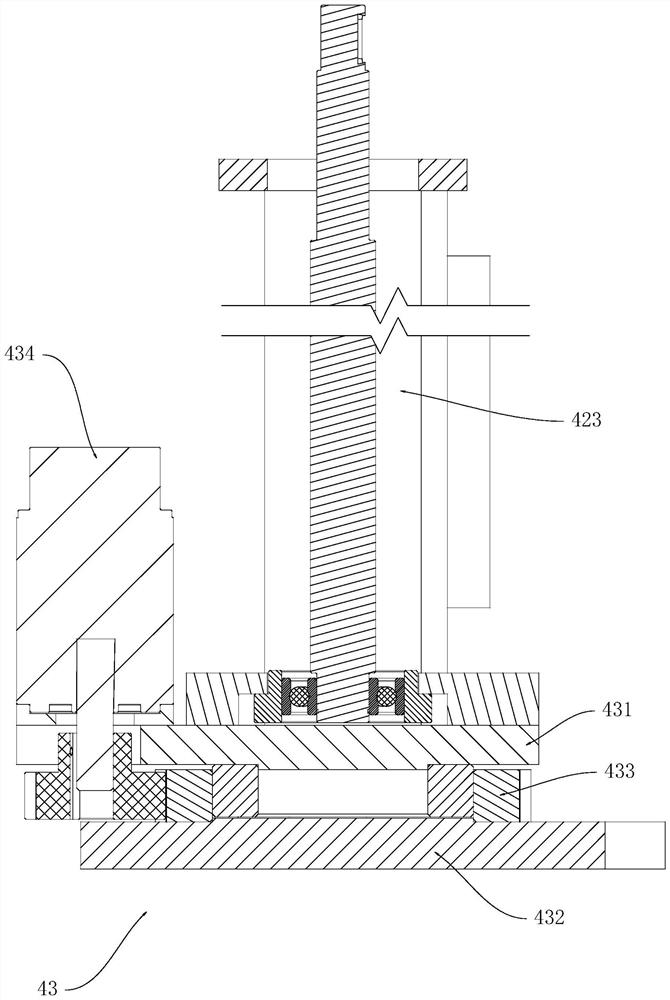

[0029] Such as Figure 1 to Figure 5 The shown automatic elbow inserting machine includes a frame 1, and the frame 1 is provided with a distributing mechanism 2 capable of arranging the elbows of the heat exchange tubes and dividing the distance between them, and a fixing mechanism for fixing the heat exchanger. Mechanism 3, and the take-up and intubation mechanism 4 for taking out the elbow of the heat exchange tube and inserting it on the heat exchanger. The present invention works like this, the material distribution mechanism 2 arranges the elbows neatly and divides the distance, the feeding and intubation mechanism 4 moves to the material distribution mechanism 2, and takes away a plurality of elbows at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com