Condenser assembly for refrigerator, refrigerator refrigeration system and refrigerator

A technology for condenser components and refrigeration systems, applied in refrigeration components, evaporators/condensers, refrigerators, etc., can solve the problems of increasing the volume of condensers, waste of pipes and auxiliary materials, and large occupied volume, and achieve reduction Effects of resistance, promotion of turbulent state, and improvement of heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

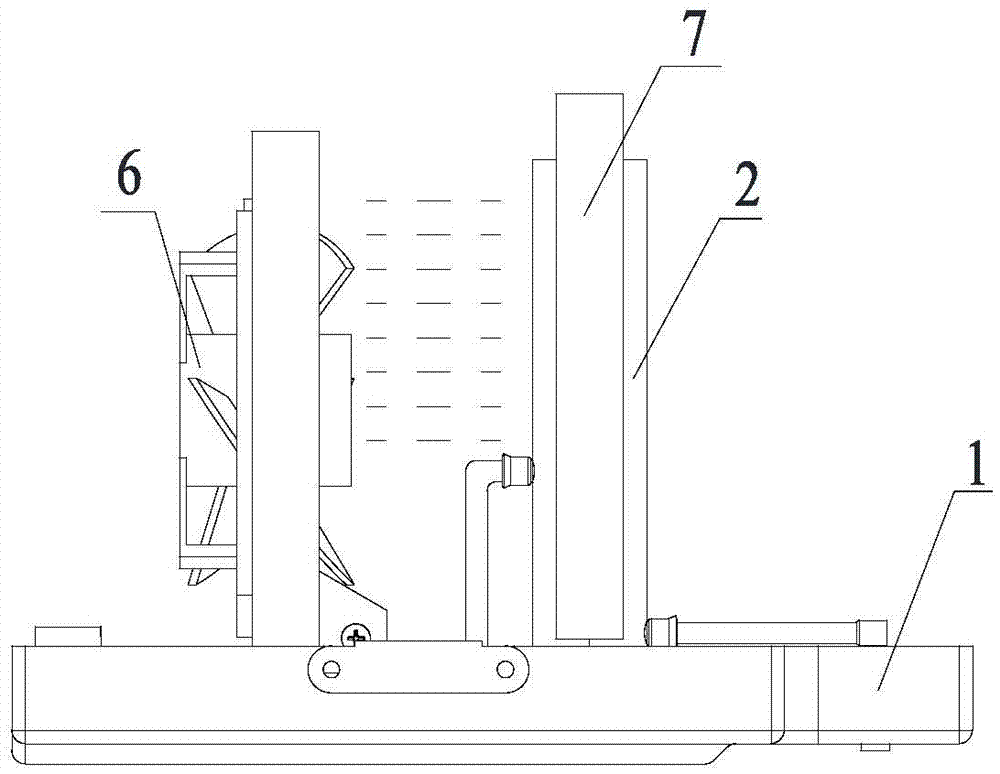

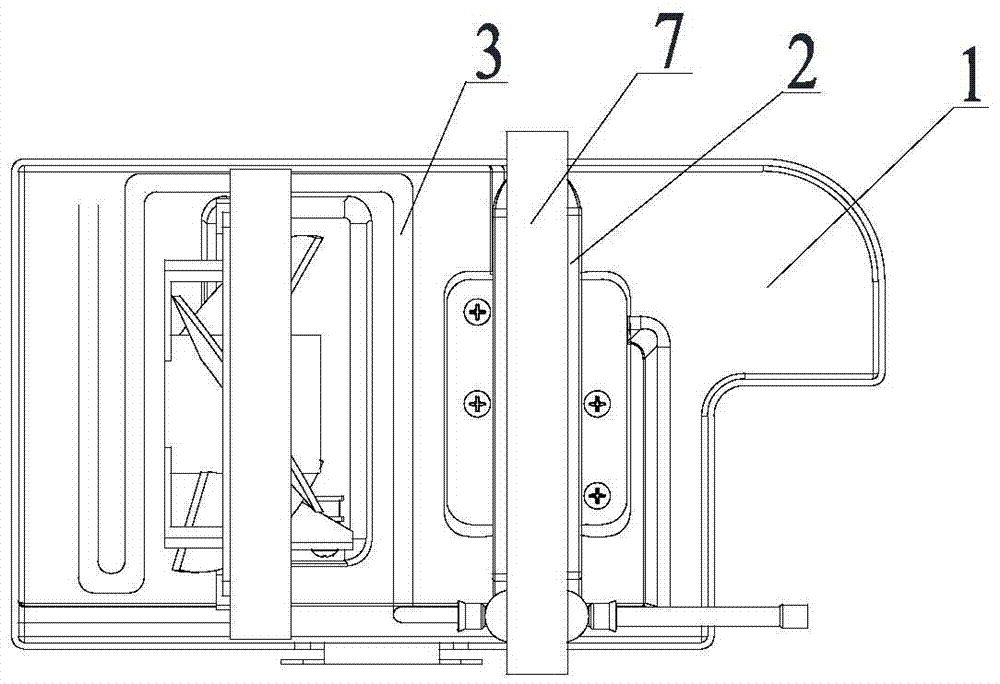

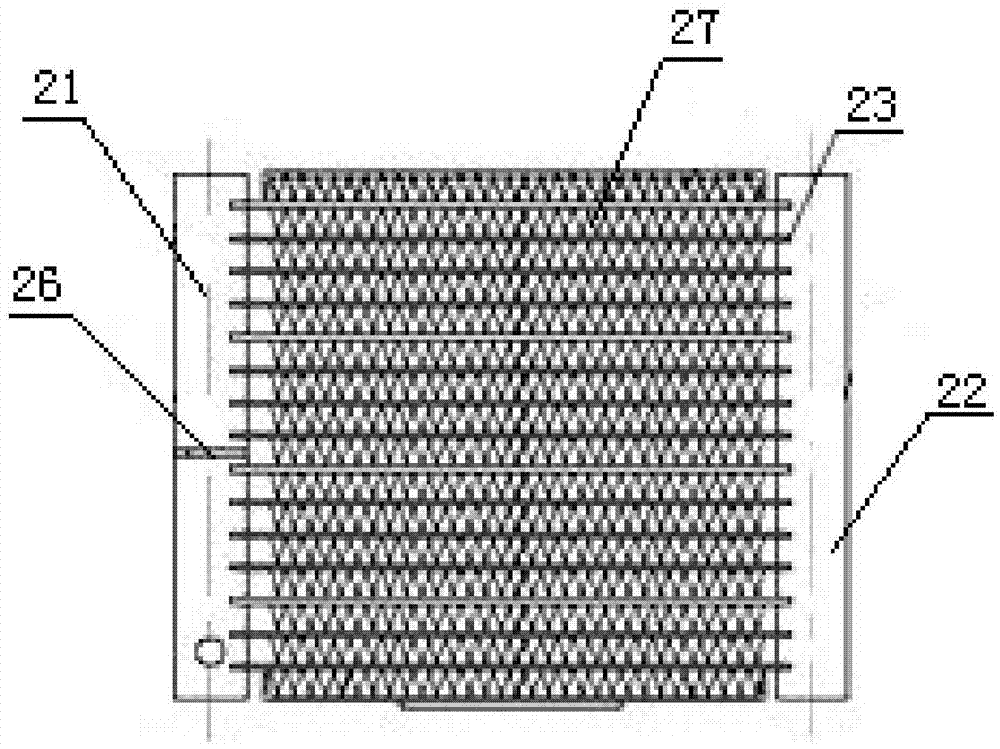

[0034] Embodiments of the present invention provide a condenser assembly for a refrigerator, such as Figure 1 to Figure 4 As shown, it includes a water receiving tray 1 and a parallel flow condenser 2 arranged on the water receiving tray 1; the parallel flow condenser 2 includes a first header 21, a second header 22, and a parallel flow condenser 2 arranged in parallel on the first header A plurality of flat tubes 23 between the flow tube 21 and the second header 22, at least a separator 26 is arranged in the first header 21, a plurality of microchannels are arranged inside the flat tubes 23, and a plurality of microchannels are arranged between the flat tubes 23. There are fins 27 , and the first header 21 , the second header 22 , the partition plate and the flat tube 23 form a circulation channel connected in sequence from end to end for the circulation of refrigerant.

[0035] In this embodiment, the gaseous refrigerant enters the first header 21 from the air inlet assembl...

Embodiment 2

[0046] This embodiment provides a refrigerator refrigeration system, such as Figure 6 As shown, it includes a compressor 4, a refrigerator assembly according to Embodiment 1, a capillary tube 8 and an evaporator 9, the compressor 4, the parallel flow condenser 2 in the condenser assembly, the capillary tube 8 and the evaporator 9 in sequence connected.

[0047] As a further embodiment, an anti-condensation tube 10 and a filter 11 are sequentially arranged on the communication channel between the parallel flow condenser 2 and the capillary tube 8 .

[0048] Furthermore, it also includes a control valve 12 arranged between the filter and the capillary, the number of the capillary is at least 2, and at least 2 capillary are arranged in parallel, the control valve 12 is used to control the opening of one of the capillary 8, the control valve 12 is preferably an electric valve. The control valve 12 can control the refrigerant to enter one of the capillary tubes according to the s...

Embodiment 3

[0052] This embodiment provides a refrigerator, which includes the refrigeration system for the refrigerator described in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com