A centrifugal fan impeller

A centrifugal fan and impeller technology, applied in the field of power machinery, can solve the problems of increased production cost, poor processing technology, easy falling off of ceramic blocks, etc., to improve energy conversion efficiency, uniform load pressure distribution, and increase impact resistance. effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

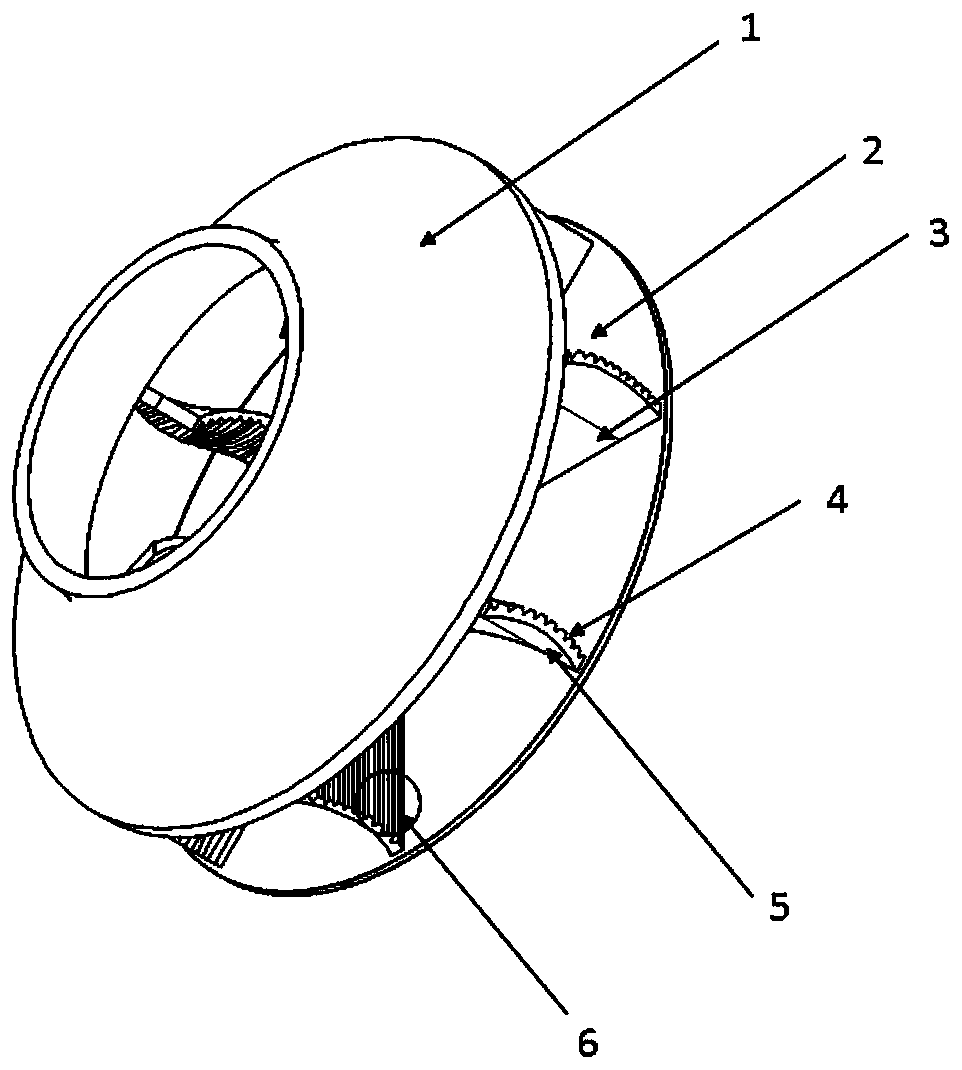

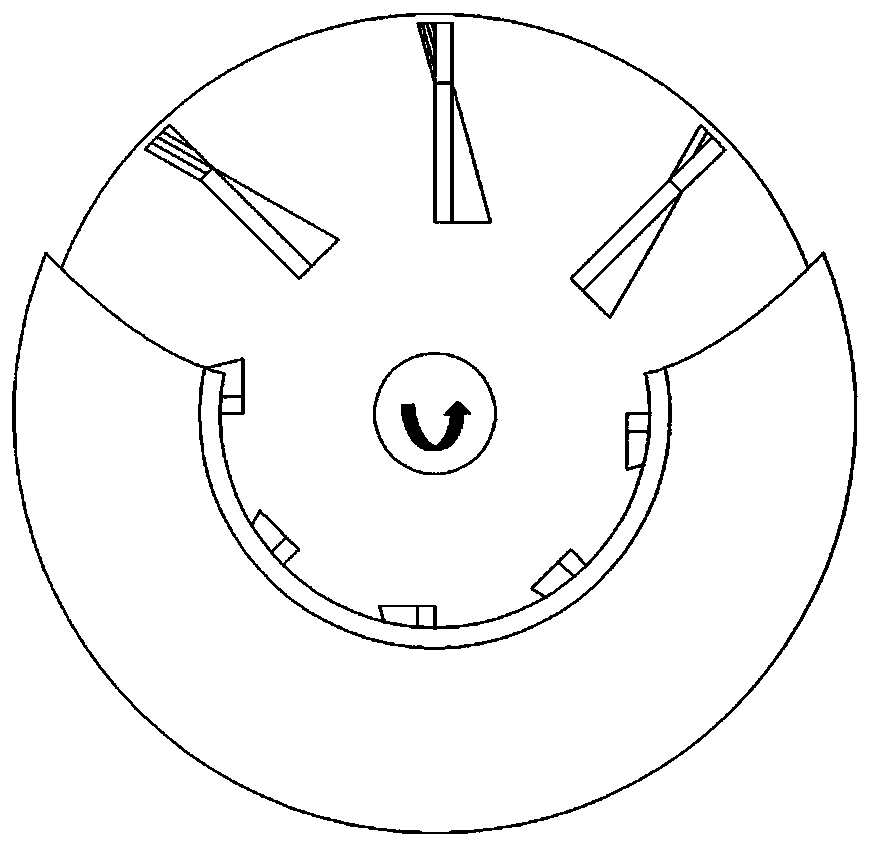

[0034] The invention provides a centrifugal fan impeller, such as Figure 1-3 As shown, the impeller includes a front disk 1, a rear disk 2 and blades 3, wherein the blade 3 has a blade pressure surface 4 and a blade suction surface 5, and its upper and lower end surfaces are fixed and formed by welding with the front disk 1 and the rear disk 2 respectively. There are a plurality of blades 3 inside, and the plurality of blades 3 are arranged in the impeller at intervals along the circumference of the impeller, and the height of the entire impeller is B2.

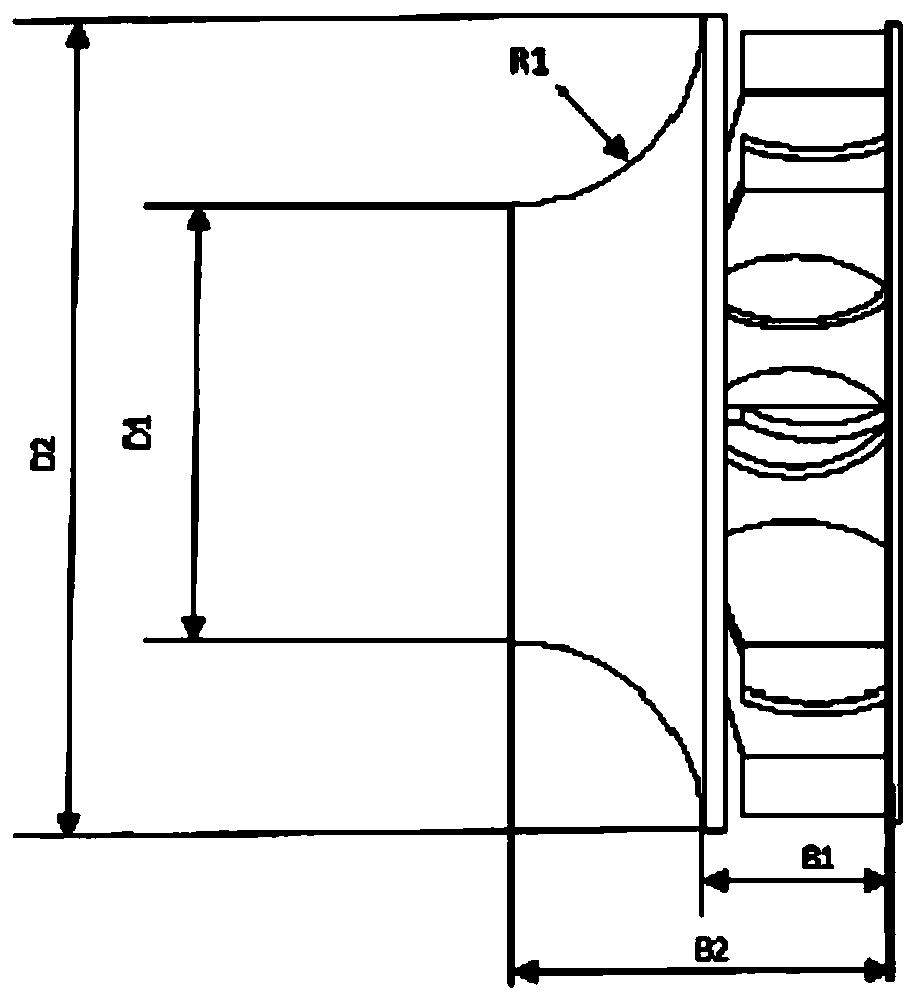

[0035] Such as image 3 , 4 As shown, the front disc 1 is a ring structure with a bell mouth shape, and the inner diameter of the ring is D1, wherein the value range of D1 is 500mm-2000mm; the section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com