Electrochemistry pole plate for processing electroplating wastewater

An electroplating wastewater and electrochemical technology, which is applied in the direction of electrochemical water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of affecting the efficiency of electrochemical equipment to treat wastewater, affecting the effect of electrochemical treatment, and not being able to obtain effective Utilize and other problems to achieve the effect of increasing the wastewater treatment capacity, shortening the residence time, and enhancing the turbulent state of the water body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

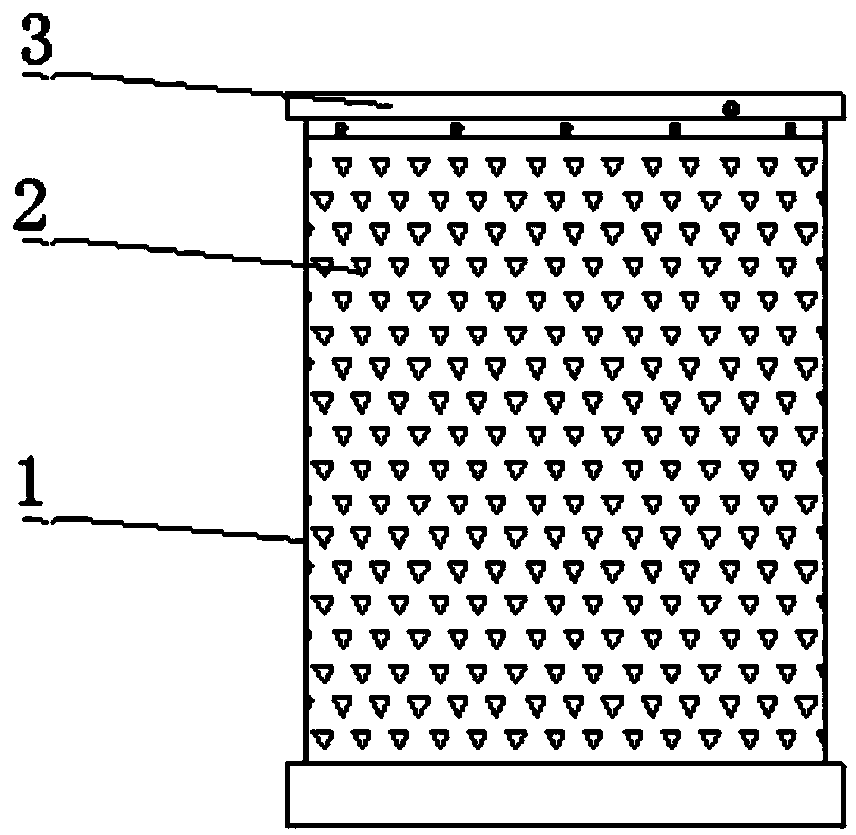

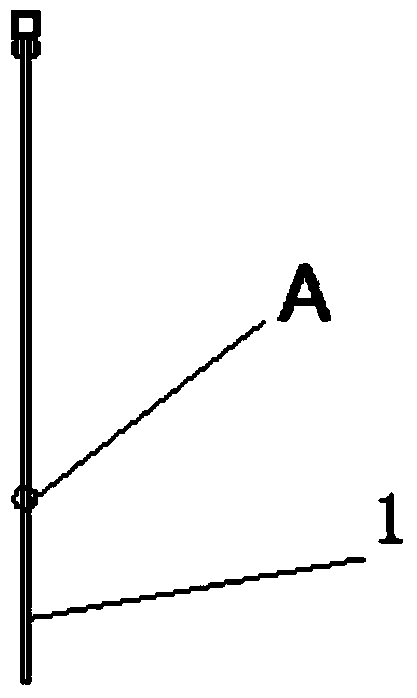

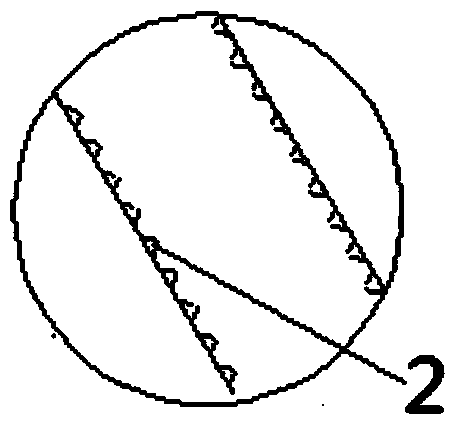

[0026] see figure 1 , 2 And 3, the electrochemical pole plate used to treat electroplating wastewater includes a pole plate body 1; several rows of pits 2 are arranged on the surface of the pole plate body 1; the diameter of the pits 2 is 5mm, and the depth is 2mm The distance between the center points of two adjacent pits 2 is 20 mm; the distance between the pits 2 on both sides of the plate body 1 and the side of the plate body 1 is 45-55 mm; The density on 1 is 0.1—0.17 pieces / cm 2 . One end of the pole plate body 1 is provided with a conductive rod 3 .

Embodiment 2

[0028] With the electrochemical pole plate described in Example 1, the electrochemical treatment equipment of copper-containing industrial wastewater in an electroplating enterprise is transformed, and the design treatment capacity of this wastewater treatment equipment is 50m 3 / h, the main pollutants to be treated are copper, lead, chromium and zinc. The original treatment equipment uses flat flat ordinary carbon steel plates as soluble plates. The surface of the plates is not treated, and the plates are directly connected to the power supply with copper plates. During the operation of the original equipment: the energy consumption per ton of water is high, the effective utilization rate of the plates is not high, the replacement cycle of the plates is short, and the weight of the scrapped plates is large. After the transformation of the present invention, the wastewater treatment equipment has been significantly improved. After one year of operation, the system has a stable ...

Embodiment 3

[0032] see Figure 4 with 5 , the electrochemical plate used to treat electroplating wastewater includes a plate body 1; the surface of the plate body 1 is provided with some rows of pits 2 and some rows of holes 4, and the ratio of the number of pits 2 to holes 4 is 3—5:1; the diameter of the pit 2 is 5mm, and the depth is 2mm; the distance between the center points of two adjacent pits 2 is 20mm; the diameter of the hole 4 is 4—8mm; two adjacent holes 4 The distance between the center points is 60mm; the distance between the pits 2 on both sides of the plate body 1 and the side of the plate body 1 is 45-55mm; the holes 4 on both sides of the plate body 1 and the side of the plate body 1 The distance is 45-55mm; the density of the pits 2 on the plate body 1 is 0.1-0.17 / cm 2 ; The density of the holes 4 on the plate body 1 is 0.03-0.05 / cm 2 . One end of the pole plate body 1 is provided with a conductive rod 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com