A kind of methanol production method and production equipment thereof

A production method and technology for production equipment, applied in the field of methanol production methods and production equipment, can solve the problems of poor inorganic sulfur desulfurization effect, affecting the decomposition and removal of organic sulfur, etc., so as to avoid uneven desulfurization, accelerate contact time, and increase turbulence. Effects of flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

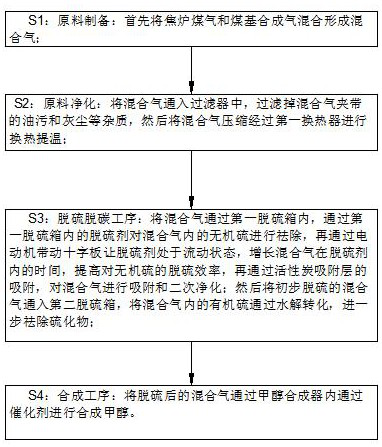

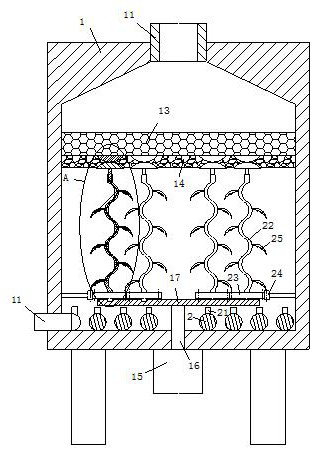

[0032] Such as Figure 1 to Figure 7 As shown, in the methanol production method described in the present invention, the steps of the methanol production method are as follows: S1: raw material preparation: firstly, coke oven gas and coal-based synthesis gas are mixed to form a mixed gas; S2: raw material purification: Pass the mixed gas into the filter to filter out impurities such as oil and dust carried by the mixed gas, and then compress the mixed gas through the first heat exchanger for heat exchange and temperature increase; S3: desulfurization and decarbonization process: pass the mixed gas through the first heat exchanger In a desulfurization box 1, the inorganic sulfur in the mixed gas is removed through the desulfurizing agent in the first desulfurizing box 1, and then the cross plate 17 is driven by the motor 15 to keep the desulfurizing agent in a flowing state, increasing the time of the mixed gas in the desulfurizing agent , to improve the desulfurization efficie...

Embodiment 2

[0042] Such as Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention, a layer of rubber layer 35 is attached to the top of the first arc-shaped block 28; during operation, in order to prevent the first arc-shaped block 28 and the activated carbon adsorption layer from A large collision noise occurs between 13, and a layer of rubber layer 35 is fixed on the first arc-shaped block 28, which can effectively reduce the generation of noise through the buffer of rubber layer 35, and will not cause damage to the activated carbon adsorption layer 13 .

[0043]Working principle: The mixed gas entering from the air guide pipe 11 will pass into the spiral pipe 2 and then be sprayed out through the air outlet pipe 21. Since the spiral pipe 2 occupies the entire bottom of the first desulfurization tank 1, the mixed gas introduced through the spiral pipe 2 can be evenly distributed. is distributed in the desulfurizing agent liquid, introduced into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com