Multi-layer vertical flow methane biological oxidation device

A biological oxidation and methane technology, applied in chemical instruments and methods, separation of dispersed particles, air quality improvement, etc., can solve the problems of easy short flow of methane biological oxidation device, poor oxygen free diffusion ability, high density of filling medium, etc., to achieve Effects of reducing global warming potential, facilitating flow, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

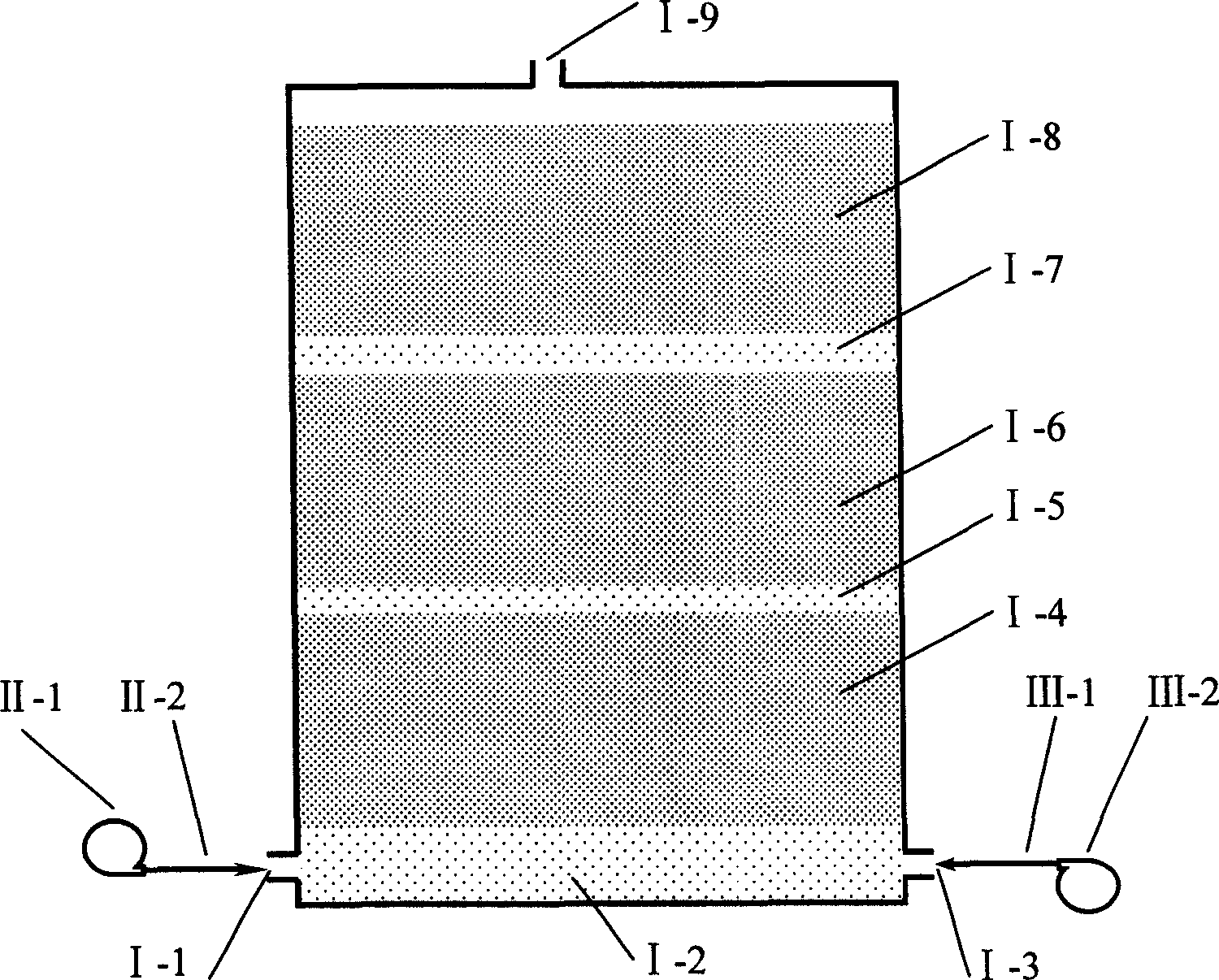

[0015] Fig. 1 shows the schematic structure of the present invention. It can be seen from Figure 1 that the multi-layer vertical flow methane biooxidation device includes: a reactor, a methane supply system and an air supply system. Specifically, the reactor consists of methane inlet I-1, gas distribution layer I-2, air inlet I-3, filling medium I-4, gas distribution layer I-5, filling medium I-6, cloth Air layer I-7, filling medium I-8 and exhaust port I-9 constitute. The air distribution layer I-2, the air distribution layer I-5 and the air distribution layer I-7 are lightweight porous ceramsite. Filling medium I-4, filling medium I-6 and filling medium I-8 are mixtures of forest soil surface loam containing methane-oxidizing bacteria and pores and lightweight porous ceramsite (the mixing ratio is 1:1). The methane supply system consists of blower II-1 and gas pipeline II-2. The air supply system consists of fan III-1 and air pipe III-2.

[0016] The course of work of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com