Flare gas system baffle molecular sealer

A technology of molecular sealer and baffle, which is applied in the field of process equipment, can solve the problems of poor reliability and heavy weight, and achieve the effects of preventing liquid accumulation, light weight and smooth fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

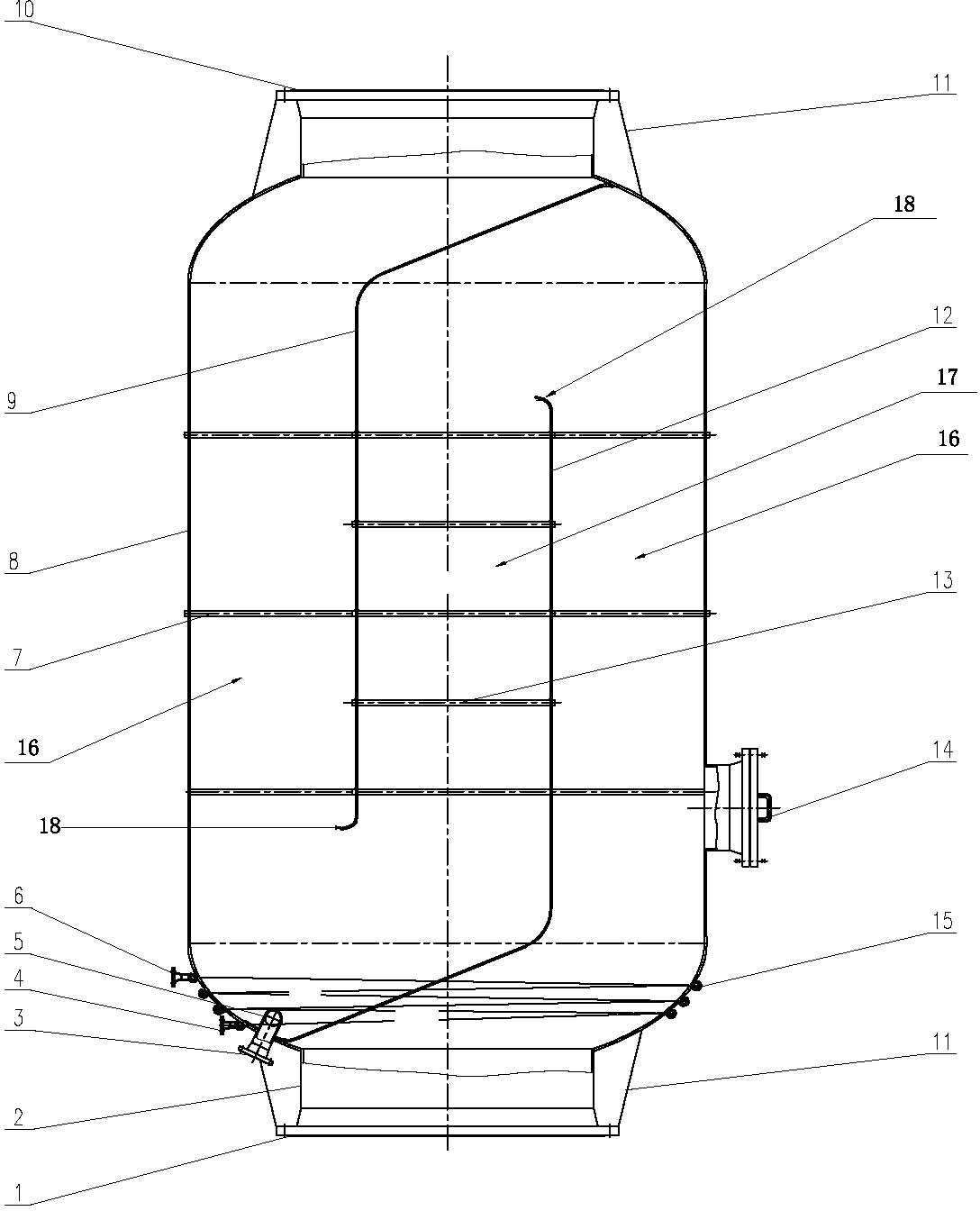

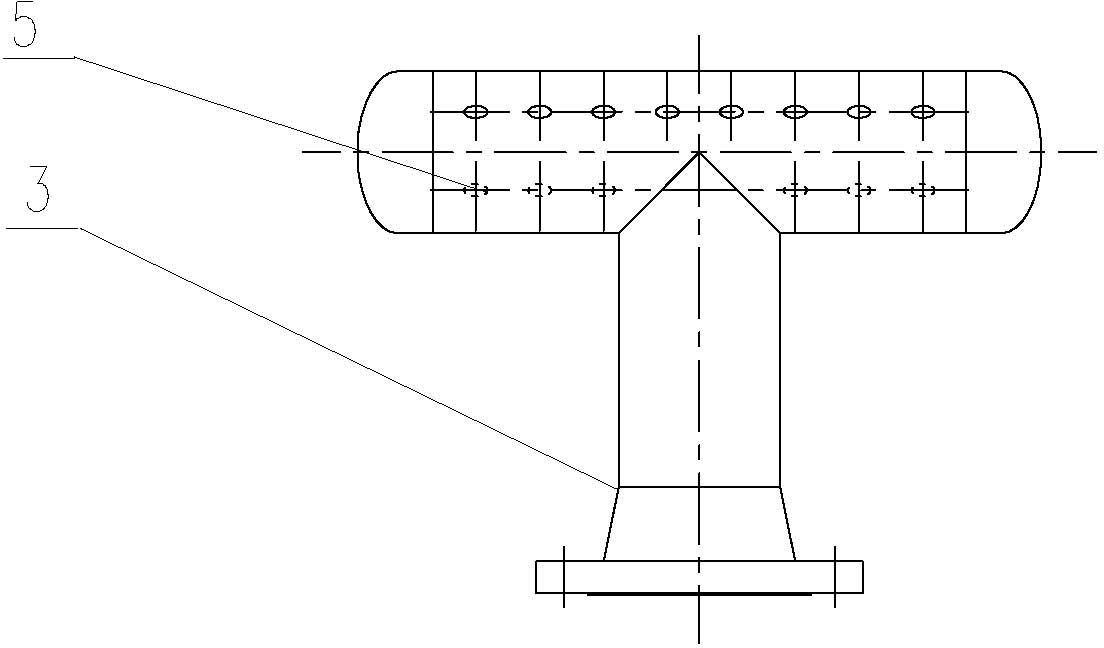

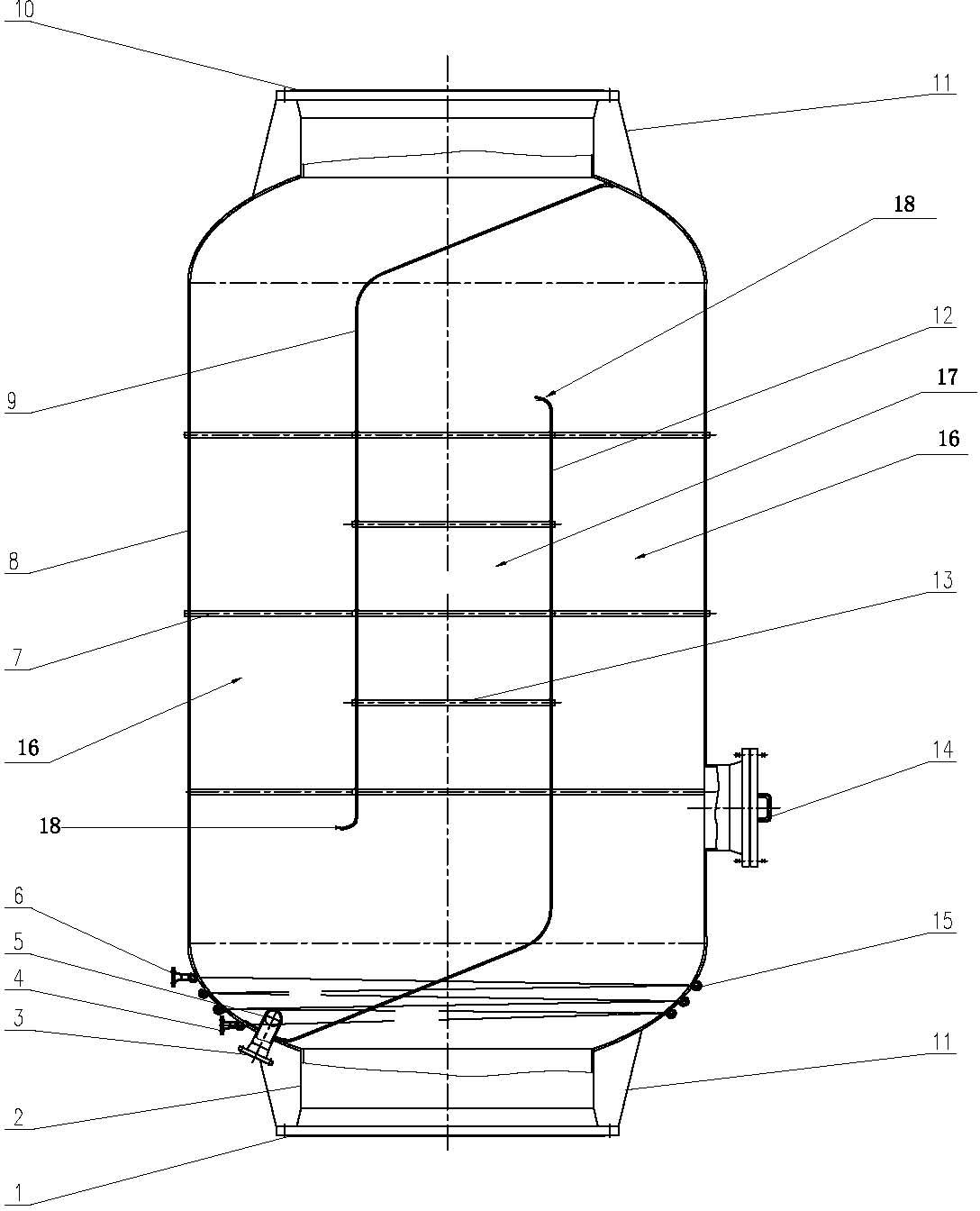

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as Figure 1-2 shown.

[0024] A baffle molecular sealer for a flare gas system, which includes a housing 8, an inlet flange 1 is installed at the lower end of the housing 8, and an outlet flange 10 is installed at the other end of the housing 8, between the inlet flange 1 and the housing 8 A stiffener plate 11 is installed between them, and a stiffener plate 11 is installed between the outlet flange 10 and the shell 8. A manhole 14 for maintenance is installed on the middle and lower part of the shell. Heating coil 15, steam condensing pipe 4 and steam inlet pipe 6 are installed, such as figure 1 As shown, an upward upward baffle 12 is installed at the entrance of the lower end of the housing 8, and the upward baffle 12 consists of an upwardly inclined arc plate connected to the entrance of the lower end of the housing 8 at one end an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com